EOS StainlessSteel PH1

Material Data Sheet

EOS StainlessSteel PH1

EOS StainlessSteel PH1 is a pre-alloyed stainless steel in fine powder form. The chemistry of EOS StainlessSteel PH1 conforms to the compositions of DIN 1.4540 and UNS S15500. This kind of steel is characterized by having good corrosion resistance and excellent mechanical properties, especially in the precipitation hardened state. This type of steel is widely used in variety of engineering applications requiring high hardness, strength and corrosion resistance. This material is ideal for many part-building applications (DirectPart) such as functional metal prototypes, small series products, individualised products or spare parts. Standard processing parameters use full melting of the entire geometry with 20 µm layer thickness. Using standard parameters the mechanical properties are fairly uniform in all directions. Parts made from EOS StainlessSteel PH1 can be machined, spark-eroded, welded, micro shot-peened, polished and coated if required.

- High strength and hardness

- Corrosion resistant

- For mildly corrosive environments

- Engineering applications including functional prototypes, small series products, individualised products or spare parts

- Parts requiring high corrosion resistance, sterilisability, etc.

- Parts requiring particularly high hardness and strength

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

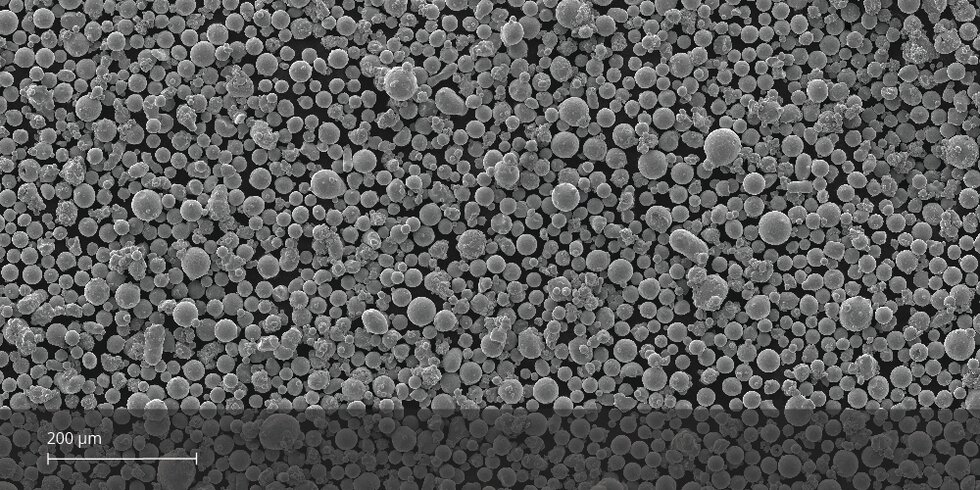

POWDER PROPERTIES

The chemistry of EOS StainlessSteel PH1 conforms to the compositions of DIN 1.4540 and UNS S15500.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Cr | 14.0 | 15.5 |

| Ni | 3.5 | 5.5 |

| Cu | 2.5 | 4.5 |

| Mn | 0.0 | 1.0 |

| Si | 0.0 | 1.0 |

| C | 0.0 | 0.07 |

| Mo | 0.0 | 0.5 |

| Nb | 0.15 | 0.45 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 20 - 65 μm | |

|---|---|---|

HEAT TREATMENT

Hardening of EOS StainlessSteel PH1 done using modified H900 heat treatment

Soaking time at precipitation hardening temperature 525°C elongated for 4 hours