EOS Titanium Ti64 Grade 23

Material Data Sheet

EOS Titanium Ti64 Grade 23

EOS Titanium Ti64 Grade 23 is a Ti6Al4V alloy with lower amount of oxygen and iron compared to the standard Ti64 alloy. The material is well-known for having excellent mechanical properties: low density with high strength and excellent corrosion resistance. EOS Titanium Ti64 Grade 23 is a titanium alloy powder intended for manufacturing parts on EOS metal systems with EOS DMLS processes.

Compared to Ti64, Ti64ELI has better elongation and toughness, but lower strength. Generally, Ti64ELI alloys are considered to be biocompatible and have low specific weight compared to CoCr alloys.

Parts built with EOS Titanium Ti64 Grade 23 powder can be machined, shot peened and polished in as manufactured and heat treated states. Due to the layerwise building method, the parts have a certain anisotropy. Heat treatment is recommended to reduce internal stresses and increase ductility.

EOS Titanium Ti64 Grade 23 powder can be used on the EOS M 290 with a 40 μm and 80 μm process and on the EOS M 400-4 with an 80 μm process.

- Low weight combined with high strength

- Excellent corrosion resistance

- High fatigue resistance compared to other lightweight alloys

- The parts fulfill chemical requirements for Grade 23 alloy

- Medical components

- Implants

- Other industrial applications where low weight in combination with high strength are required

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

EOS Titanium Ti64 Grade 23 powder is classified as Grade 23 titanium alloy according to ASTM B348. The chemical composition is in compliance with standards ASTM F136, ASTM F3001, and ASTM F3302.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Ti | Balance | |

| Al | 5.5 | 6.5 |

| V | 3.5 | 4.5 |

| O | 0.0 | 0.13 |

| N | 0.0 | 0.05 |

| C | 0.0 | 0.08 |

| H | 0.0 | 0.012 |

| Fe | 0.0 | 0.25 |

| Y | 0.0 | 0.005 |

| Other Elements Each | 0.0 | 0.1 |

| Other Elements Total | 0.0 | 0.4 |

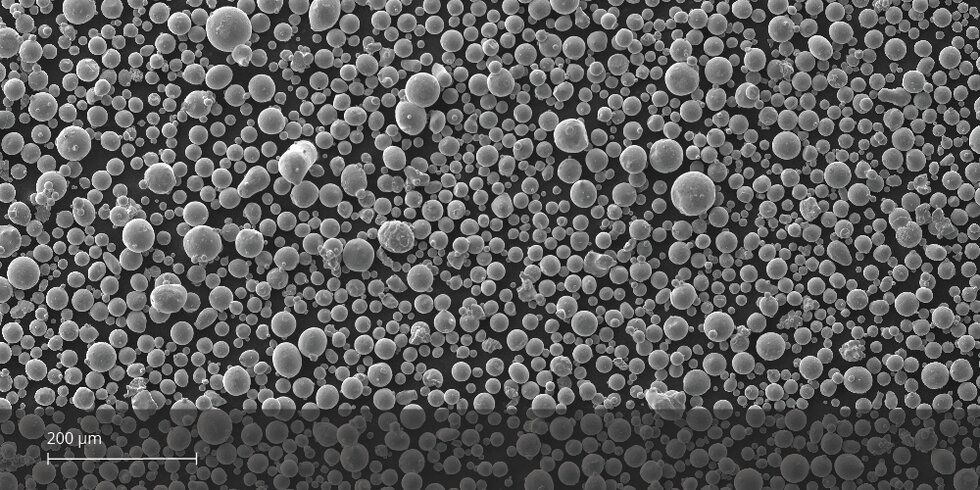

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 20 - 80 μm | |

|---|---|---|

SEM micrograph of EOS Titanium Ti64 Grade 23 powder

HEAT TREATMENT

As manufactured microstructure for additively manufactured Ti64 consists of fully acicular alpha prime (α‘) phase. Standard heat treatments for titanium do not necessarily produce desired microstructures due to this different starting microstructure. Heat treatment is recommended to relieve stresses and to increase ductility. Use of vacuum furnace is highly recommended to avoid the formation of alpha case on the surface of the parts.

120min (± 30 min) at 800 °C (± 10°C) measured from the part in vacuum (1.3x10-3-1.3x10-5 mbar) followed by slow cooling under vacuum or argon.

Material mechanical properties are relatively insensitive to changes in heating and cooling rates, but longer treatment times may result in decreased strength and increased elongation.

Parts heat treated according to the recommended heat treatment have a microstructure consisting of fine alpha + beta (α + β) phase.