EOS Aluminium Al5X1

Material Data Sheet

EOS Aluminium Al5X1

High Strength & High Elongation Aluminium for AM

EOS Aluminium Al5X1 is a heat-treatable aluminium alloy designed for AM to offer a compelling combination of high strength and high elongation. Al5X1 exhibits excellent mechanical properties with a strength above 400 MPa and an elongation exceeding 13% after heat treatment. The recommended single-step heat treatment does not require a water quench and enables robust part production.

- Excellent combination of strength & elongation

- Good corrosion resistance

- Parts can be anodized

- Aerospace

- Automotive

- Marine

- Lightweight designs

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

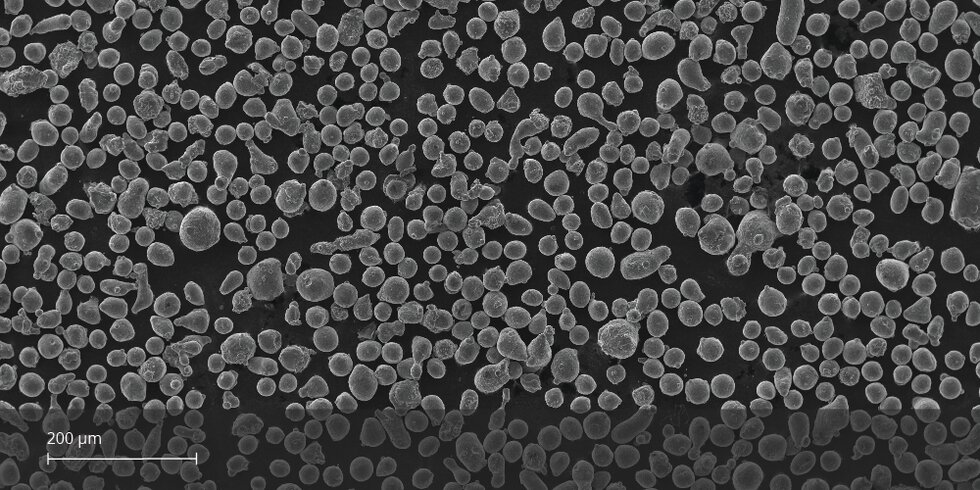

POWDER PROPERTIES

The chemical composition of EOS Aluminium Al5X1 is specially designed for AM. Powder composition values shown below are typical.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Al | Balance | |

| Mg | 2.5 | 4.2 |

| Zr | 0.6 | 1.8 |

| Mn | 0.1 | 1.0 |

| Fe | 0.0 | 1.0 |

| Si | 0.0 | 1.0 |

| Ti | 0.0 | 1.0 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 20 - 63 μm | |

|---|---|---|

SEM micrograph of EOS Aluminium Al5X1 powder

HEAT TREATMENT

Heat treatment procedure

Direct ageing heat treatment

6 hours at 400 °C. Immediate gas quenching (air cooling with maximal air flow).

Preferred inert atmosphere during furnace treatment.

EOS Aluminium Al5X1 for EOS M 290 | 40 µm

EOS M 290 - 40 µm - TRL 3

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | Al5X1_040_CoreM291_100 |

| Software Requirements |

EOSPRINT 2.11 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | 4.8 mm³/s |

Chemical and Physical Properties of Parts

The chemical properties of the parts are the same as that of the powder.

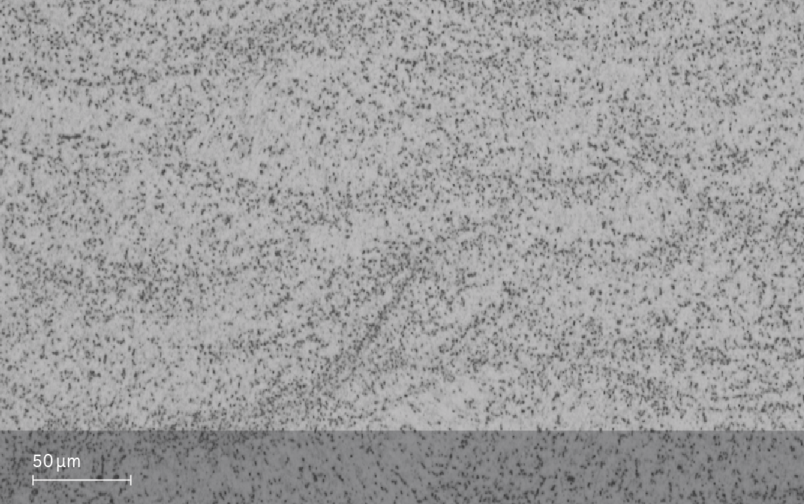

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | 0.15 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

Mechanical Properties

Mechanical Properties Heat Treated

| ASTM E8 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 380 | 415 | 14.5 | - | - | - |

| Horizontal | 385 | 415 | 14.5 | - | - | - |

ASTM E8, strain rate 0.00762 mm/s

Mechanical Properties As Manufactured

| Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 240 | 310 | 23 | - | - | - |

| Horizontal | 260 | 310 | 23 | - | - | - |

Hardness

| Heat Treated | |

|---|---|

| Value | 127 |

| Unit | HBW 2.5/62.5 |

| Heat Treated | |

|---|---|

| Value | 71 |

| Unit | HRB |

| As Manufactured | |

|---|---|

| Value | 86 |

| Unit | HBW 2.5/62.5 |

| As Manufactured | |

|---|---|

| Value | 40 |

| Unit | HRB |

Thermal Conductivity

| ASTM E1461-13 | Orientation | [W/m*K] |

|---|---|---|

| Heat Treated | Vertical | 132 |

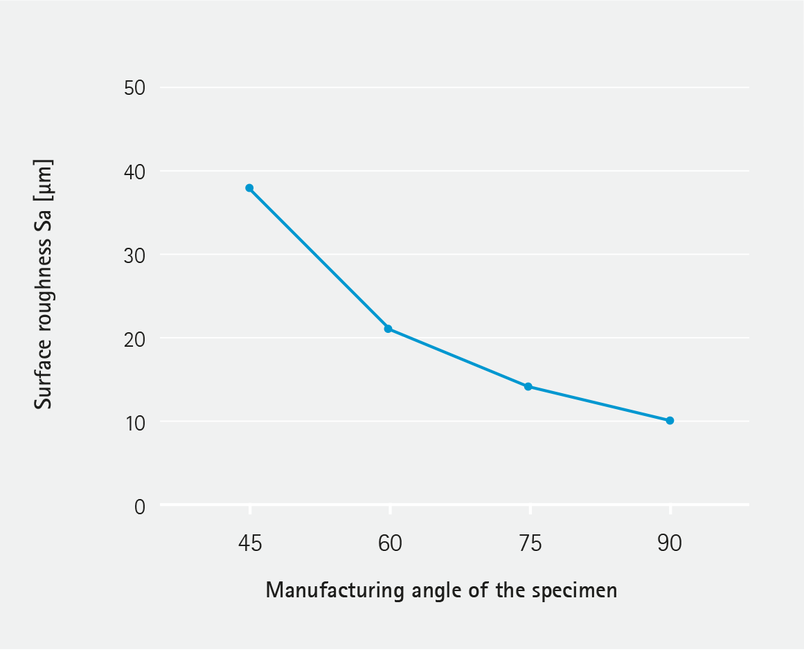

Surface Roughness

Specific heat capacity at 25°C

| AST E1269-11 Heat Treated | |

|---|---|

| Value | 0.87 |

| Unit | J/g/°C |

Anodization

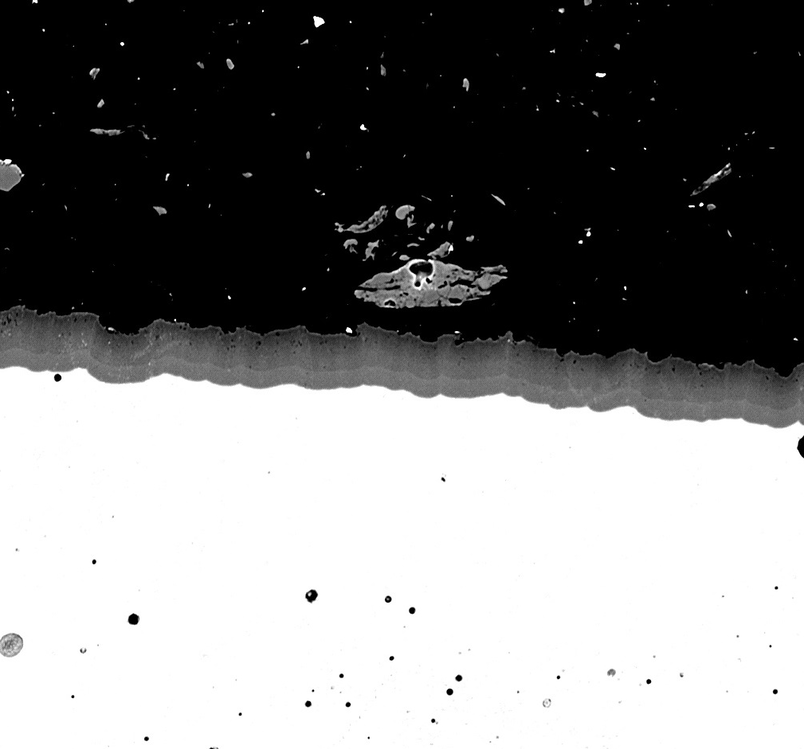

SEM image of the anodizing layer.

Anodized according to Mil-A-8625 Type III

Thickness of anodization layer

depends on used anodization

process.

Electrical Conductivity

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| As Manufactured | 40 µm | | Vertical | 23 |

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| Heat Treated | 40 µm | | Vertical | 34 |