EOS Aluminium AlF357

Material Data Sheet

EOS Aluminium AlF357

Light Weight & Corrosion Resistance

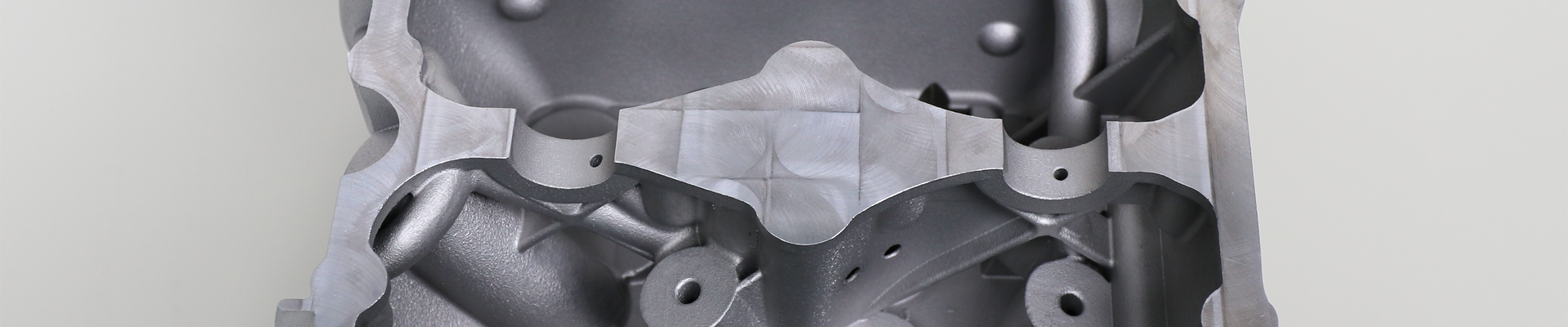

EOS Aluminium AlF357 is an ideal material for applications requiring a combination of low weight and mechanical/thermal load endurance. It is a beryllium free derivative of the A357 (AlSi7Mg0.6) alloy. Parts built of EOS Aluminium AlF357 can be machined, shot-peened and polished in the as-built or heat treated state. For this product, a T6-like heat treatment may be utilized to enhance the overall mechanical properties.

- Light-weight

- Corrosion resistance

- High dynamic load bearing capacity

- Aerospace industry applications

- Defense and automotive industries

- Structural components requiring high strength

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

Chemical composition of the EOS Aluminium AlF357 powder is in compliance with SAE AMS 4289 standard.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Al | Balance | |

| Si | 6.5 | 7.5 |

| Fe | 0.0 | 0.1 |

| Cu | 0.0 | 0.2 |

| Mn | 0.0 | 0.1 |

| Mg | 0.4 | 0.7 |

| Zn | 0.0 | 0.1 |

| Ti | 0.04 | 0.2 |

| Be | 0.0 | 0.002 |

| Other Elements Each | 0.0 | 0.05 |

| Other Elements Total | - | 0.15 |

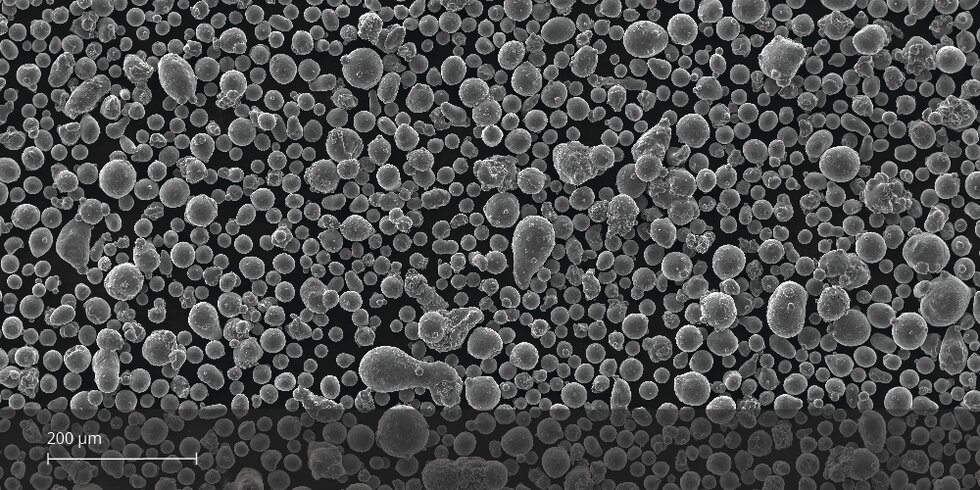

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 20 - 90 μm | |

|---|---|---|

SEM micrograph of EOS Aluminium AlF357 powder

HEAT TREATMENT

Laser melting process comprises extremely fast melting and re-solidification. Due to the layerwise manufacturing method, the parts exhibit anisotropic properties depending on the building direction. Suitable heat treatments can be used to meet the needs of various applications, e.g. to reduce the anisotropy. Conventionally cast components of this type of aluminum alloy are often heat treated using a T6 cycle consisting of solution annealing, quenching and age hardening. A T6-like heat treatment has been specifically developed to increase the ductility and yield strength, and to reduce the anisotropy of the built parts, consisting of the following cycles:

Solution Annealing: 30 minutes at 540 °C (±6 °C) measured from the part, followed by instant quenching in water at room temperature.

Aging: 6 hours at 165 °C (±6 °C) measured from the part, followed by air cooling. This step is carried out with a maximum delay of 40 hours after the solution annealing. The mechanical properties for the heat treated condition have been attained through the described heat treatment procedure.

EOS Aluminium AlF357 for EOS M 290 | 30 µm

EOS M 290 - 30 µm - TRL 7

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | AlF357_030_M291_100 |

| Software Requirements |

EOSPRINT 2.5 or newer EOSYSTEM 2.10 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Nitrogen |

| Sieve | 106 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 30 µm |

| Volume Rate | 5.8 mm³/s |

Chemical and Physical Properties of Parts

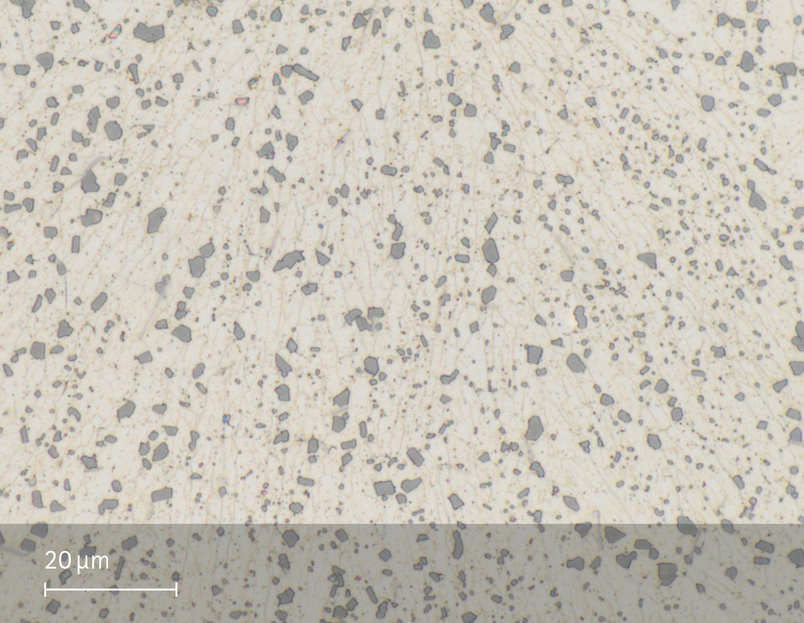

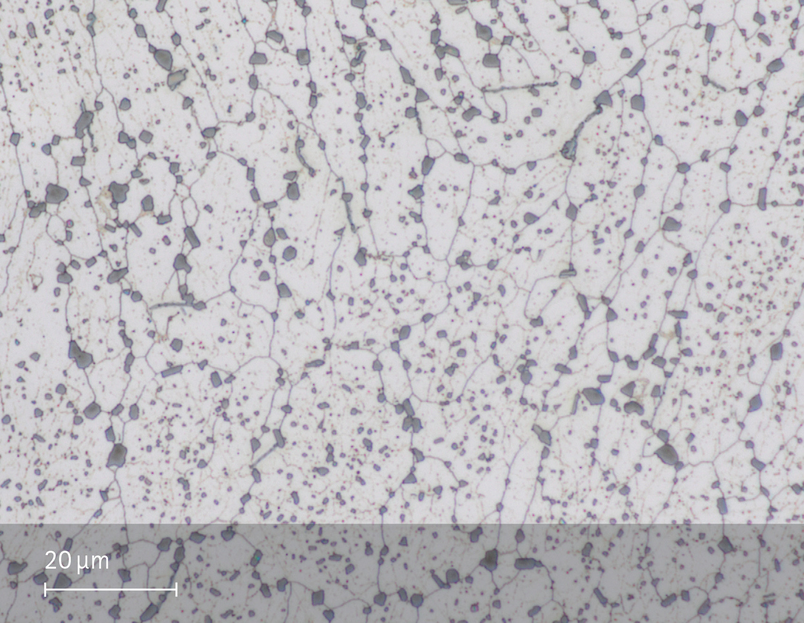

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 30 µm | 0.03 % | 20 |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

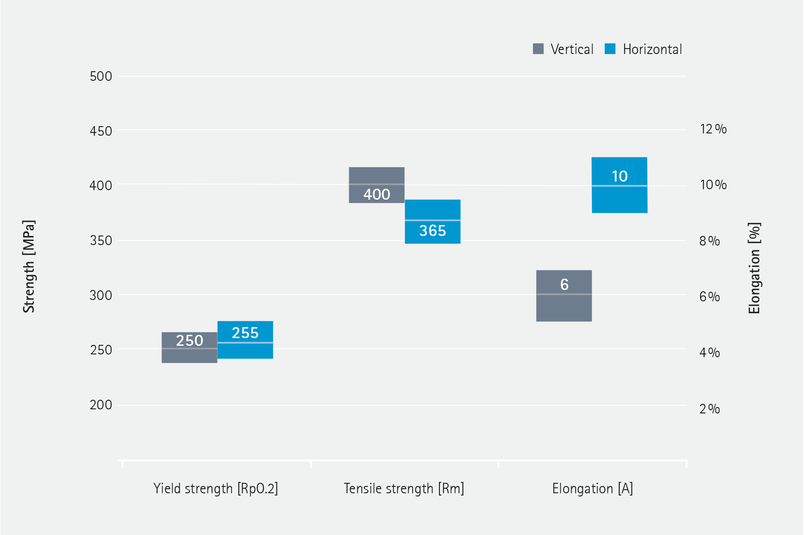

Mechanical Properties As Manufactured

| EN 2002-001 2005 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 250 | 400 | 6 | - | - | - |

| Horizontal | 255 | 365 | 10 | - | - | - |

EN 2002-001 2005 on round specimen machined according to standard Annex C

Mechanical Properties Heat Treated

| EN 2002-001 2005 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 265 | 330 | 11.5 | - | - | - |

| Horizontal | 270 | 340 | 11.5 | - | - | - |

Laser melting process comprises extremely fast melting and re-solidification.

Due to the layerwise manufacturing method, the parts exhibit anisotropic properties depending on

the building direction. Suitable heat treatments can be used to meet the needs of various applications, e.g. to

reduce the anisotropy. Conventionally cast components of this type of aluminum alloy are often heat treated using a T6 cycle consisting of solution annealing, quenching and age hardening. A T6-like heat treatment has been specifically developed to increase the ductility and yield strength, and to reduce the anisotropy of the built parts, consisting of the following cycles:

Solution Annealing:

30 minutes at 540 °C (±6 °C) measured from the part, followed by instant quenching in water at room temperature.

Aging:

6 hours at 165 °C (±6 °C) measured from the part, followed by air cooling.

This step is carried out with a maximum delay of 40 hours after the solution annealing.

The mechanical properties for the heat treated condition have been attained through the described heat treatment procedure.

Thermal Conductivity

| EN ISO 22007-2 | Orientation | [W/m*K] |

|---|---|---|

| As Manufactured | Vertical | 140 |

| As Manufactured | Horizontal | 140 |

Hot Disk slab method (xy-plane) and Hot Disk 1D-method (Z-direction)

| EN ISO 22007-2 | Orientation | [W/m*K] |

|---|---|---|

| Heat Treated | Vertical | 150 |

| Heat Treated | Horizontal | 150 |

T6 Heat Treatment

Hot Disk slab method (xy-plane) and Hot Disk 1D-method (Z-direction)

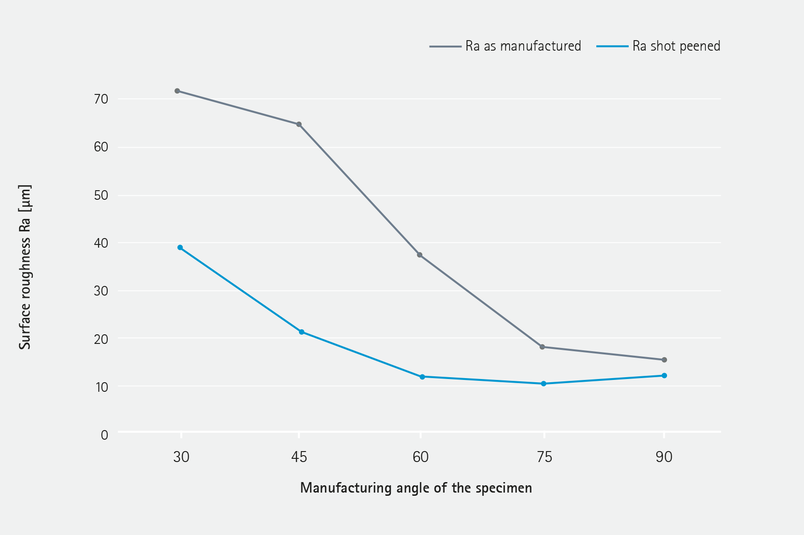

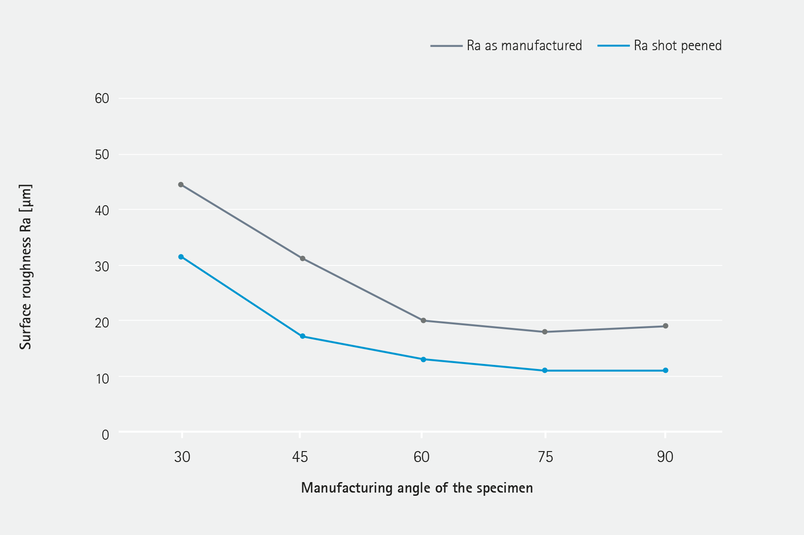

Surface Roughness

Electrical Conductivity

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| As Manufactured | 30 µm | Default | Horizontal | 28-36 |

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| Heat Treated | 30 µm | Default | Horizontal | 35-40 |

T6 Heat Treatment

Electrical conductivity measured according to ASTM E1004 Standard Test Method for Determining Electrical Conductivity

Using the Electromagnetic (Eddy Current) Method.

EOS Aluminium AlF357 for EOS M 400 | 60 µm

EOS M 400 - 60 µm - TRL 7

| System Setup | EOS M 400 |

|---|---|

| EOS Material set | AlF357_060_FlexM400_100 |

| Software Requirements |

EOSPRINT 1.6 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | Standard |

| Inert gas | Nitrogen |

| Sieve | 106 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 60 µm |

| Volume Rate | 17 mm³/s |

Chemical and Physical Properties of Parts

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 60 µm | 0.16 % | 30 |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

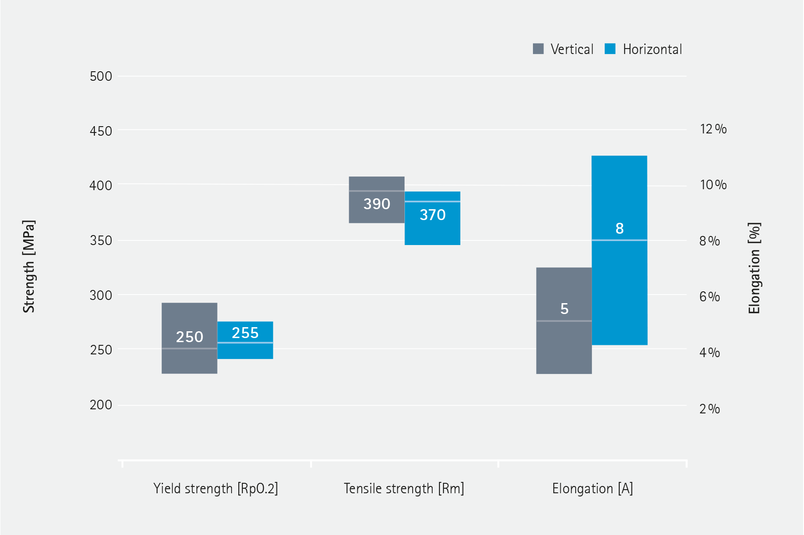

Mechanical Properties As Manufactured

| EN 2002-001 2005 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 250 | 390 | 5 | - | - | - |

| Horizontal | 255 | 370 | 8 | - | - | - |

EN 2002-001 2005 on round specimen machined according to standard Annex C

Mechanical Properties Heat Treated

| EN 2002-001 2005 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 265 | 330 | 11.5 | - | - | - |

| Horizontal | 270 | 340 | 11.5 | - | - | - |

Laser melting process comprises extremely fast melting and re-solidification.

Due to the layerwise manufacturing method, the parts exhibit anisotropic properties depending on

the building direction. Suitable heat treatments can be used to meet the needs of various applications, e.g. to

reduce the anisotropy. Conventionally cast components of this type of aluminum alloy are often heat treated using a T6 cycle consisting of solution annealing, quenching and age hardening. A T6-like heat treatment has been specifically developed to increase the ductility and yield strength, and to reduce the anisotropy of the built parts, consisting of the following cycles:

Solution Annealing:

30 minutes at 540 °C (±6 °C) measured from the part, followed by instant quenching in water at room temperature.

Aging:

6 hours at 165 °C (±6 °C) measured from the part, followed by air cooling.

This step is carried out with a maximum delay of 40 hours after the solution annealing.

The mechanical properties for the heat treated condition have been attained through the described heat treatment procedure.

Thermal Conductivity

| EN ISO 22007-2 | Orientation | [W/m*K] |

|---|---|---|

| As Manufactured | Vertical | 140 |

| As Manufactured | Horizontal | 140 |

Hot Disk slab method (xy-plane) and Hot Disk 1D-method (Z-direction)

| EN ISO 22007-2 | Orientation | [W/m*K] |

|---|---|---|

| Heat Treated | Vertical | 150 |

| Heat Treated | Horizontal | 150 |

T6 Heat Treatment

Hot Disk slab method (xy-plane) and Hot Disk 1D-method (Z-direction)

Surface Roughness

Electrical Conductivity

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| As Manufactured | 60 µm | | Horizontal | 28-36 |

Electrical conductivity measured according to ASTM E1004 Standard Test Method for Determining Electrical Conductivity

Using the Electromagnetic (Eddy Current) Method.

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| Heat Treated | 60 µm | | Horizontal | 35-40 |

T6 Heat Treatment