EOS Aluminium AlSi10Mg

Material Data Sheet

EOS Aluminium AlSi10Mg

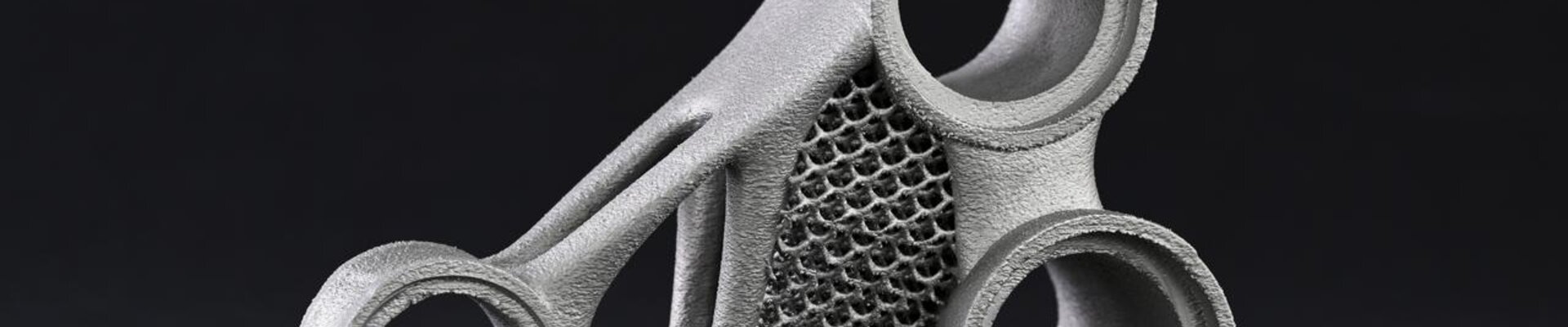

Good Strength & Dynamic Load Bearing Capacity

EOS Aluminium AlSi10Mg is a widely used alloy that combines light weight and good mechanical properties. Different heat treatments can be applied to modify properties for example to increase ductility and conductivity. The material has good thermal and electrical conductivity especially after heat treatment. In addition, gas tight parts can be manufactured with EOS Aluminium AlSi10Mg.

- Good strength, hardness and dynamic properties

- High corrosion resistance

- Good thermal and electrical conductivity

- Properties can be modified with heat treatments

- General engineering components and parts subject to high loads

- Lightweight designs

- Aerospace and automotive components

- Substitution of cast AlSi10Mg parts

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

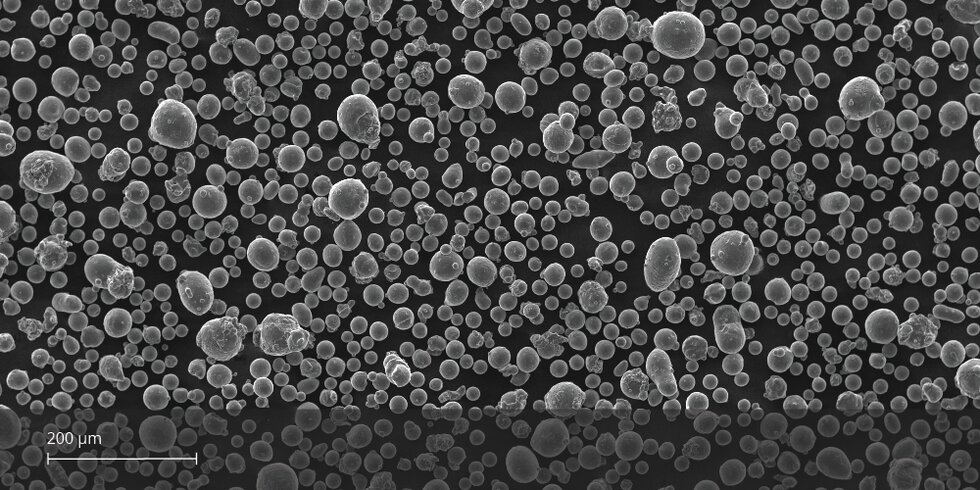

POWDER PROPERTIES

The chemical composition of the EOS Aluminium AlSi10Mg powder is in compliance with the DIN EN 1706 (EN AC—43000) and ASTM F3318 standard.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Al | Balance | |

| Si | 9.0 | 11.0 |

| Fe | 0.0 | 0.55 |

| Cu | 0.0 | 0.05 |

| Mn | 0.0 | 0.45 |

| Mg | 0.2 | 0.45 |

| Ni | 0.0 | 0.05 |

| Zn | 0.0 | 0.1 |

| Pb | 0.0 | 0.03 |

| Sn | 0.0 | 0.05 |

| Ti | 0.0 | 0.15 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 25 - 70 μm | |

|---|---|---|

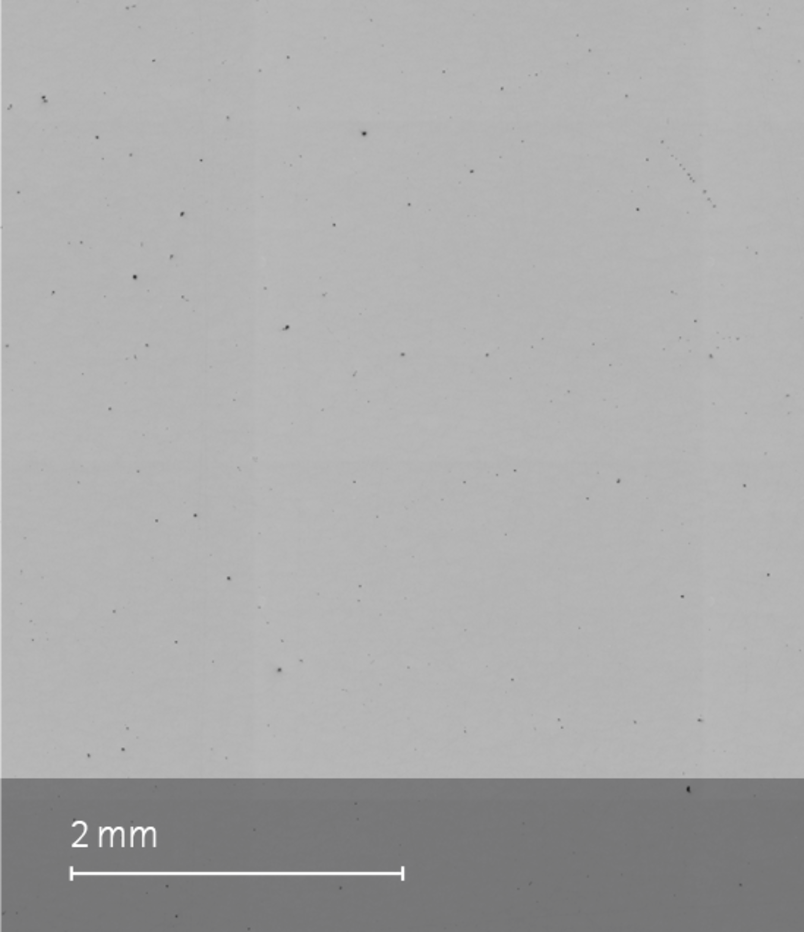

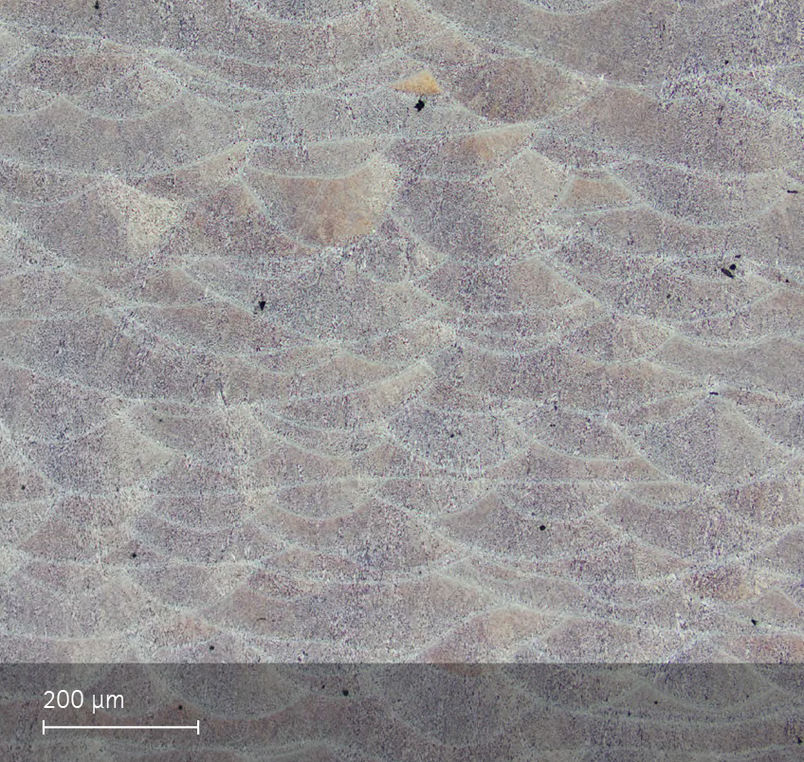

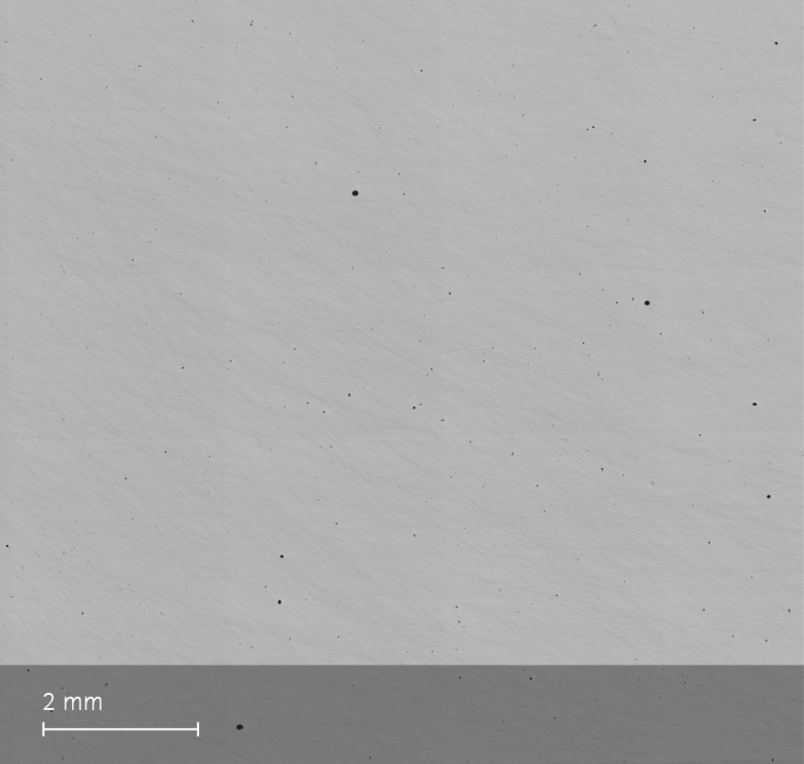

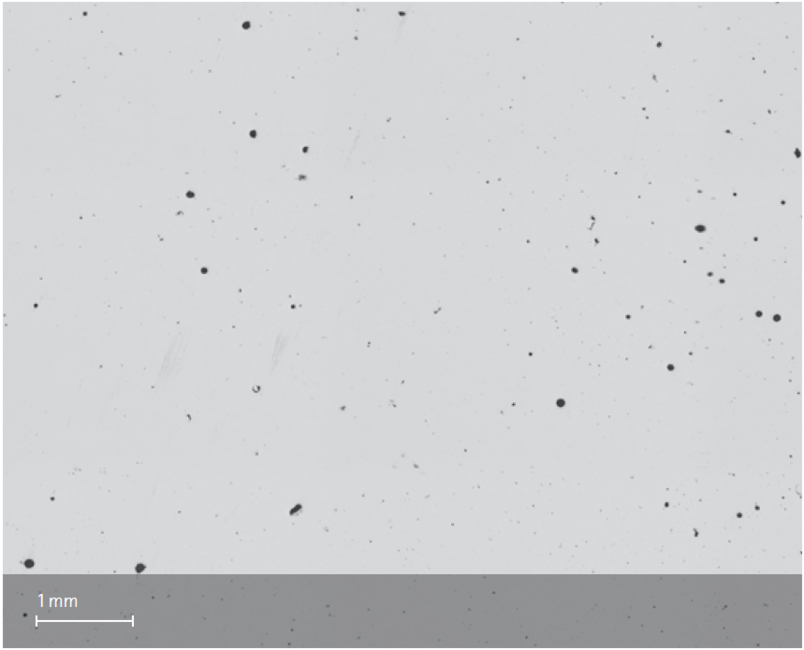

SEM micrograph of EOS Aluminium AlSi10Mg powder

HEAT TREATMENT

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40% shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment). An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing

30 minutes in 530 °C followed by immediate quenching to water.

Aging

Artificial aging of 6 hours in 165 °C followed by cooling in air.

EOS Aluminium AlSi10Mg for EOS M 290 | 30 µm

EOS M 290 - 30 µm - TRL 9

Process Information Metal

High performance process with smooth and shiny surfaces. Process is developed to have high density

with smooth vertical surfaces. T6 heat treatment enables excellent elongation with moderate strength and reduced anisotropy.

Main Characteristics:

→ Good mechanical properties and low amount of defects.

→ Shiny and smooth surfaces on vertical areas.

→ Mechanical properties can be modified with heat treatment.

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | AlSi10Mg_FlexM291 2.01 |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 35 °C |

| Nozzle | Standard |

| Inert gas | Argon |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 30 µm |

| Volume Rate | 5.1 mm³/s |

| Wall Thickness | 0.4 mm |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with DIN EN 1706 (EN AC—43000) and ASTM F3318-18 standards.

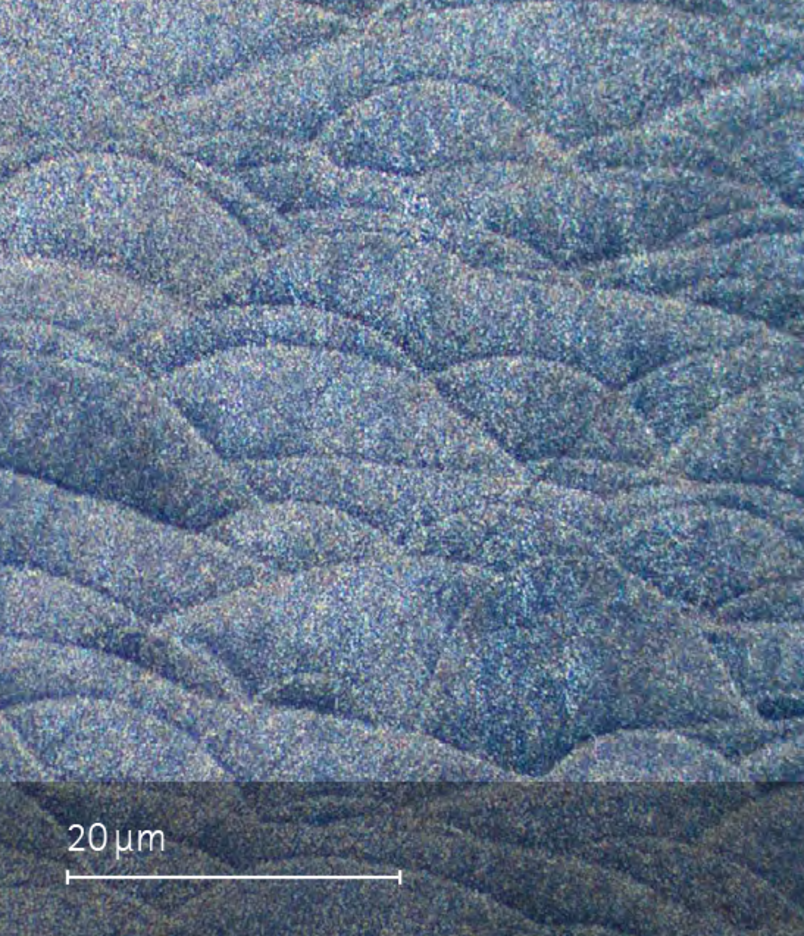

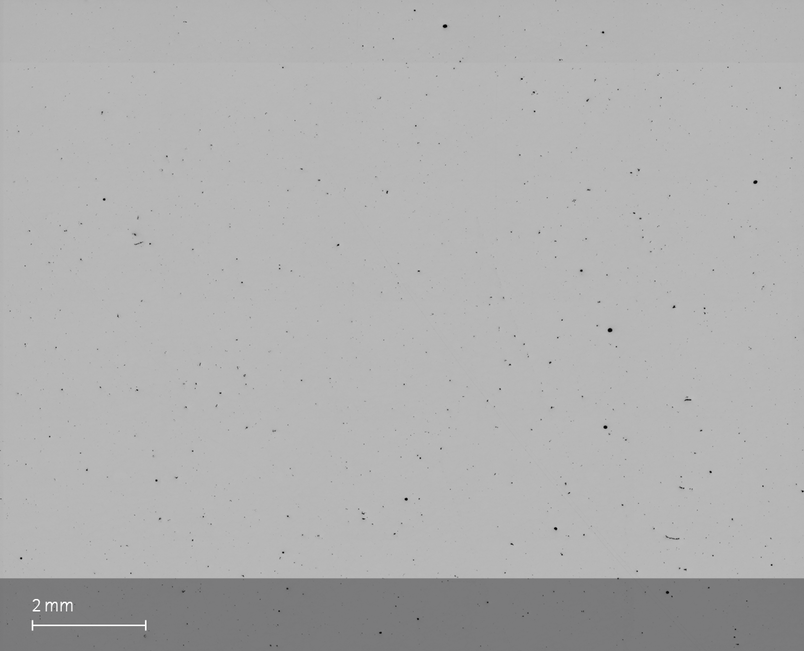

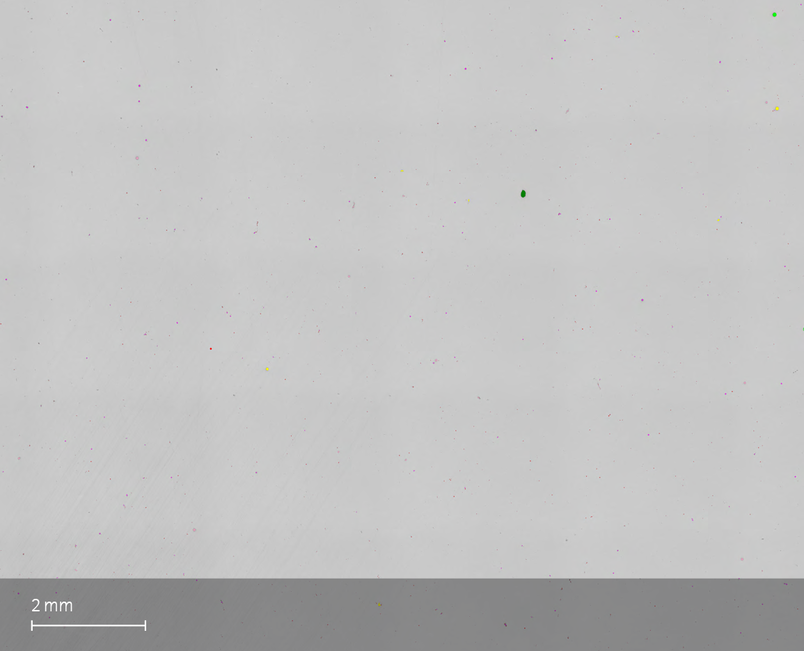

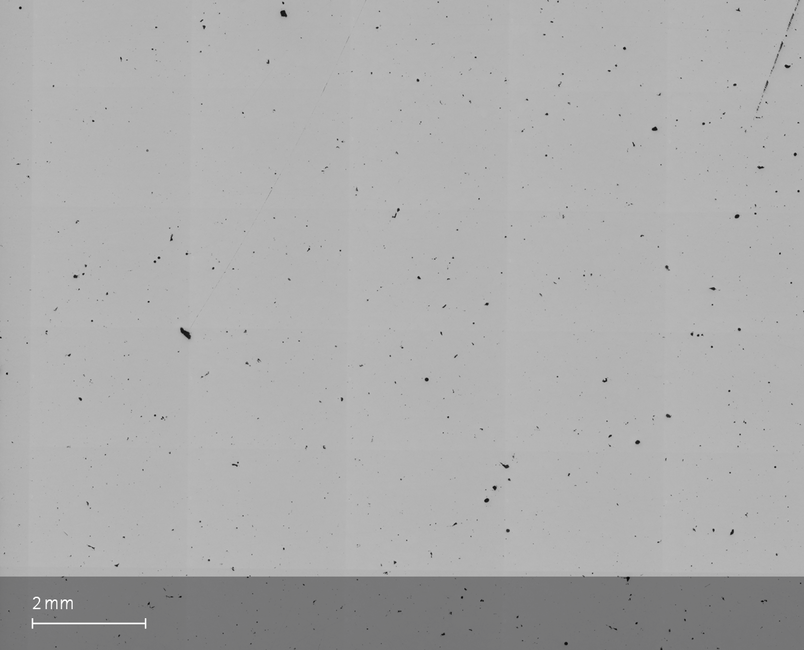

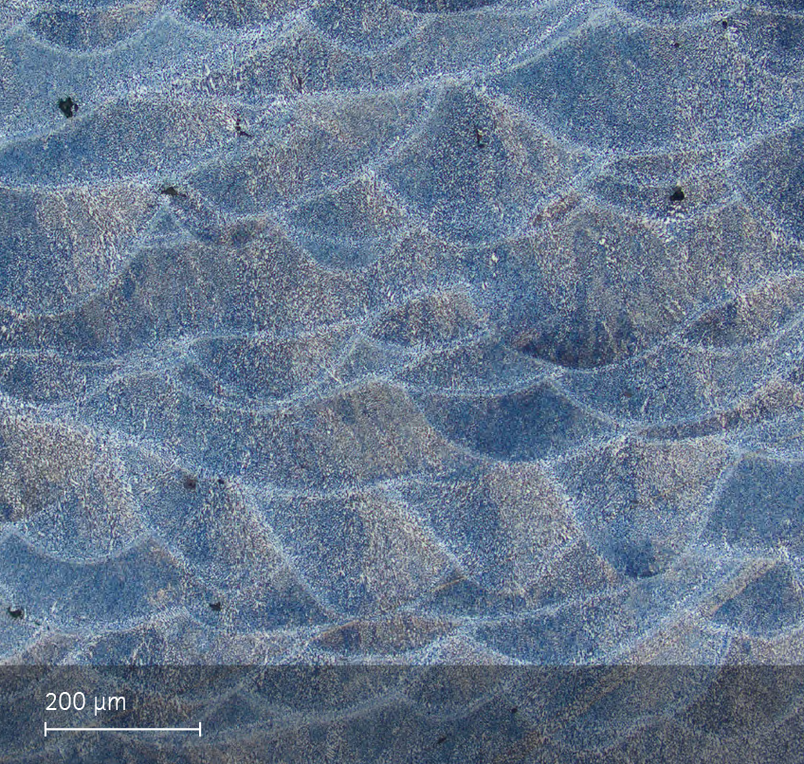

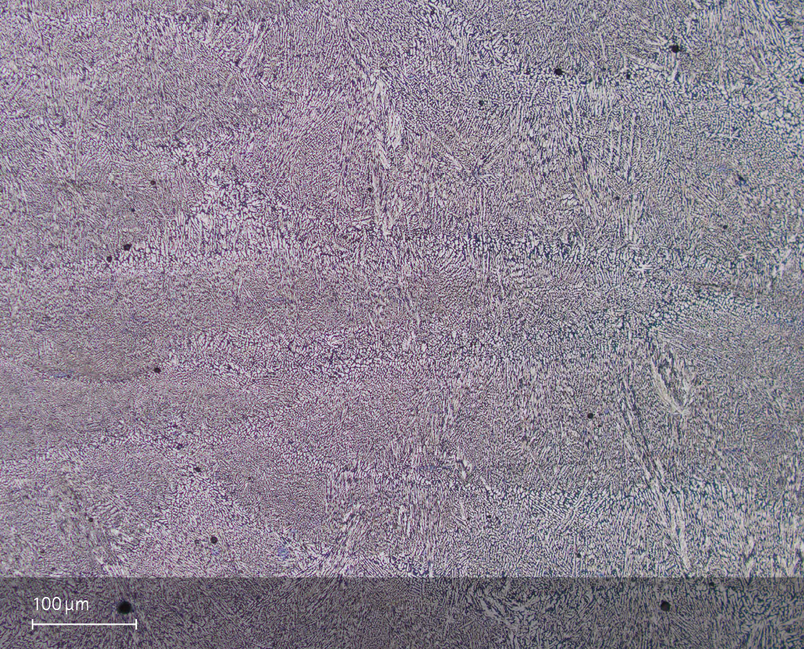

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 30 µm | 0.04 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 250 | 310 | 11 | - | - | - |

| Horizontal | 260 | 320 | 11 | - | - | - |

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40 % shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment).

An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing:

30 minutes in 530 °C followed by immediate quenching to water.

Aging:

Artificial aging of 6 hours in 165 °C followed by cooling in air.

In case higher build platform temperature is used it is strongly advised to perform EOS T6 heat treatment in order to obtain mechanical properties similar to those stated in the MDS.

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 233 | 466 | 6.3 | - | - | - |

| Horizontal | 270 | 461 | 10.2 | - | - | - |

Hardness

| EN ISO 6506 As Manufactured | |

|---|---|

| Value | 114 HBW |

| Unit | HBW2.5/62.5 |

| EN ISO 6506 Heat Treated | |

|---|---|

| Value | 105 |

| Unit | HBW 2.5/62.5 |

Fatigue

| As Manufactured | |

|---|---|

| Fatigue strength [MPa] | 110 |

HCF, ASTM E466-15, 20 million cycles, turned, fully reversed.

High cycle fatigue testing performed on machined vertical and horizontal samples. No heat treatment. A

luminum alloys do not have fatigue limit. Actual fatigue values depend on sample geometry and specially surface finish.

Thermal Conductivity

| EN ISO 22007-2 | Orientation | [W/m*K] |

|---|---|---|

| As Manufactured | Vertical | 100 |

| As Manufactured | Horizontal | 110 |

| EN ISO 22007-2 | Orientation | [W/m*K] |

|---|---|---|

| Heat Treated | Vertical | 165 |

| Heat Treated | Horizontal | 155 |

EOS T6 Heat treatement

| EN ISO 22007-2 | Orientation | [W/m*K] |

|---|---|---|

| Stress-relieved | Vertical | 160 |

| Stress-relieved | Horizontal | 165 |

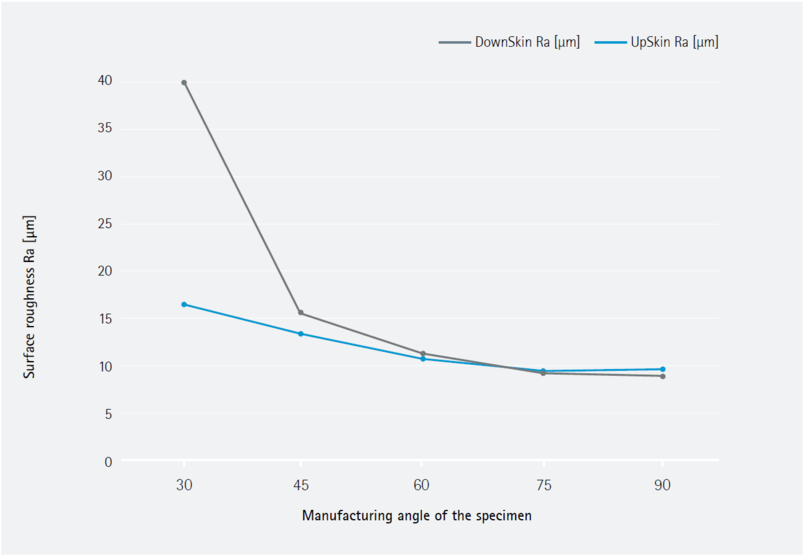

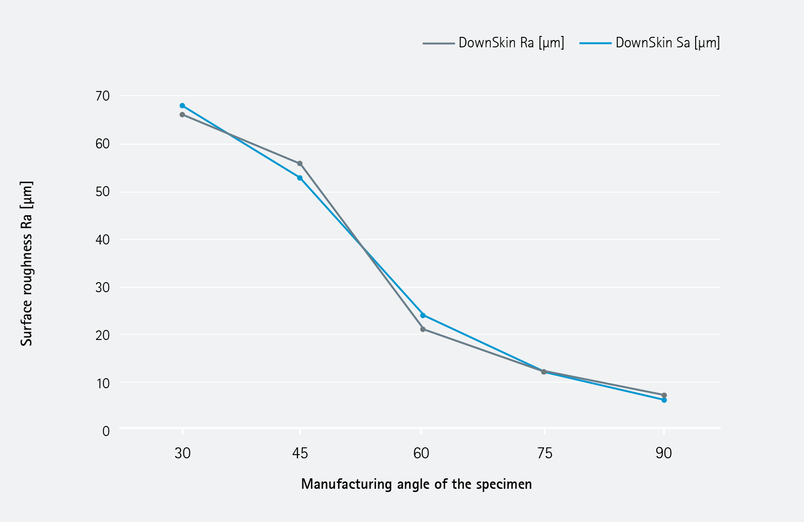

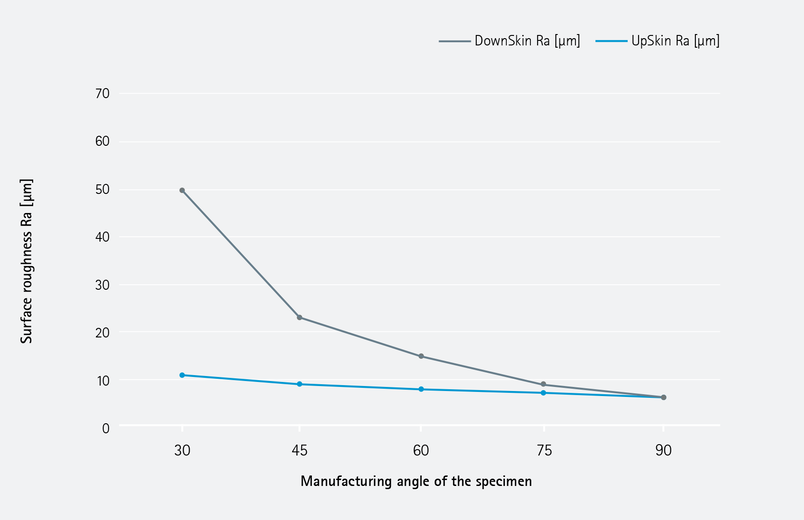

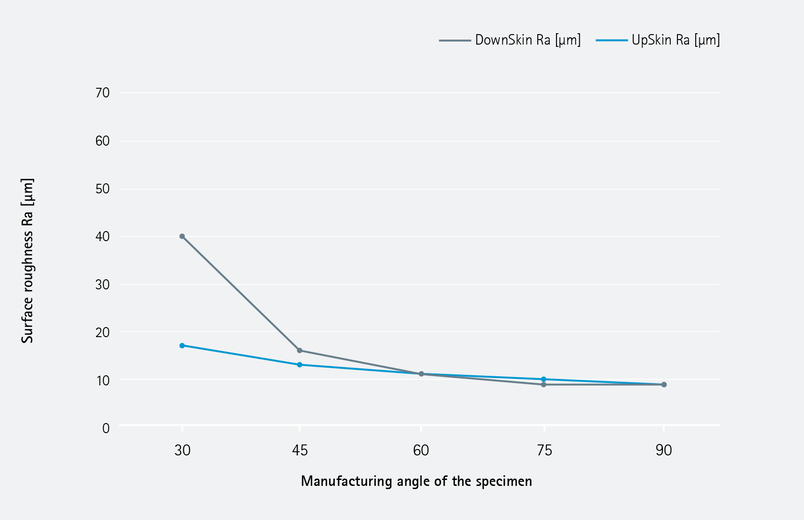

Surface Roughness

Typical gas tightness with helium leak test (2 mm wall thickness)

EN 13185:2001 |

|

|---|---|

| Value |

10*6 |

| Unit |

mbar l/s |

Electrical Conductivity

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| As Manufactured | 30 µm | | Horizontal | 25 |

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| Heat Treated | 30 µm | | Horizontal | 44 |

EOS T6 Heat treatement

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| Stress-relieved | 30 µm | | Horizontal | 44 |

Coefficient of Thermal Expansion

| ASTM E228 | Temperature |

|---|---|

| 20*10-6/K | 25 – 100 ºC |

| 22*10-6/K | 25 – 200 ºC |

| 27*10-6/K | 25 – 300 ºC |

EOS Aluminium AlSi10Mg for EOS M 290 | 60 µm

EOS M 290 - 60 µm - TRL 3

Process Information Metal

Higher productivity process can be used where mechanical requirements are less demanding but

where cost-efficiency is needed. The 60 μm EOS M 290 process has high resolution of fine features and buildabilty of thin walls.

Heat treatment can be used to affect mechanical properties.

Main Characteristics:

→ Increased productivity of aluminum parts with EOS M 290

→ Good mechanical properties

→ Good buildability of challenging geometries

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | AlSi10Mg_060_CoreM291_100 |

| Software Requirements |

EOSPRINT 2.6 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 100 °C |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 60 µm |

| Volume Rate | 10.5 mm³/s |

| Wall Thickness | 0.3 mm |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with DIN EN 1706 (EN AC—43000) and ASTM F3318-18 standards.

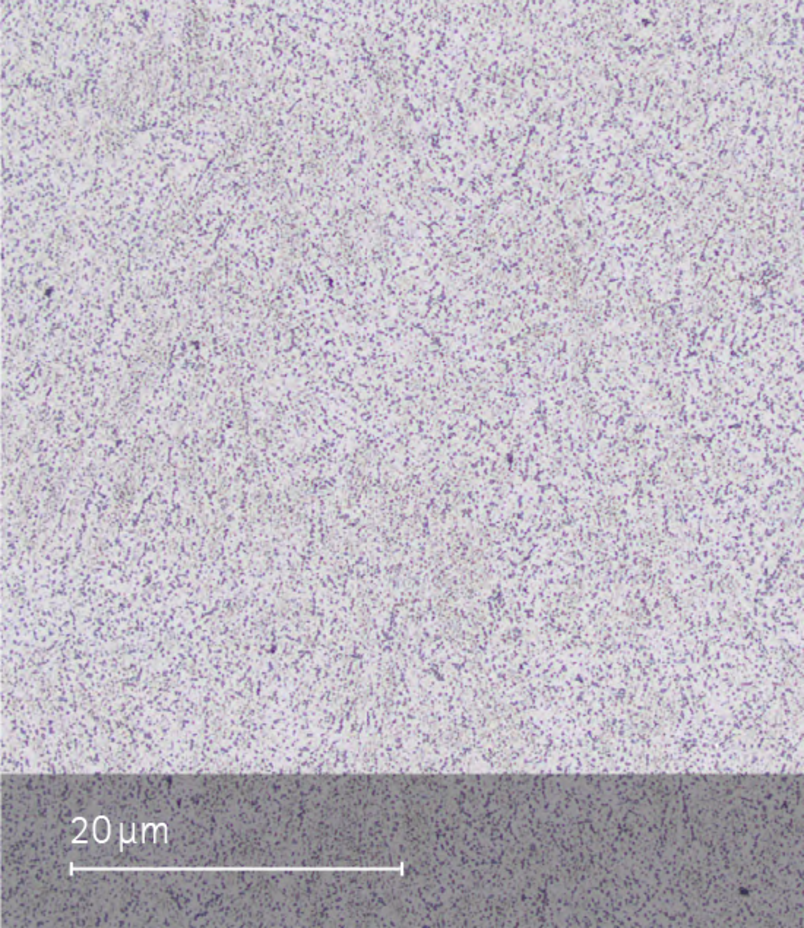

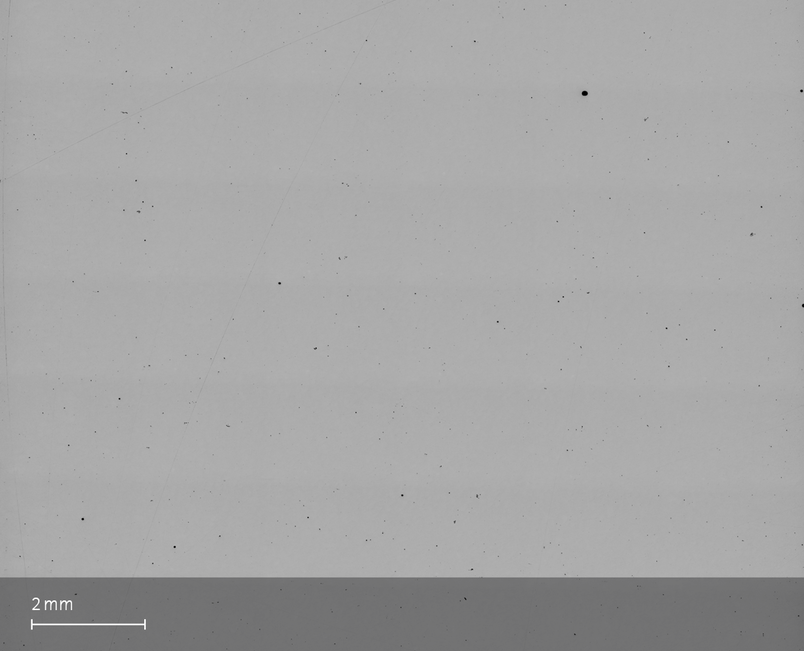

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 60 µm | 0.2 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 250 | 320 | 8 | - | - | - |

| Horizontal | 260 | 320 | 9 | - | - | - |

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40 % shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment).

An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing:

30 minutes in 530 °C followed by immediate quenching to water.

Aging:

Artificial aging of 6 hours in 165 °C followed by cooling in air.

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 240 | 440 | 4.5 | - | - | - |

| Horizontal | 250 | 440 | 7.5 | - | - | - |

Surface Roughness

EOS Aluminium AlSi10Mg for EOS M 300-4 | 60 µm

EOS M 300-4 - 60 µm - TRL 3

Process Information Metal

Process with high productivity and good mechanical properties.

Main Characteristics:

→ Good mechanical properties and high productivity combined

→ Heat treatment can be used to affect mechanical properties

| System Setup | EOS M 300-4 |

|---|---|

| EOS Material set | AlSi10Mg_060_CoreM304 |

| Software Requirements |

EOSPRINT 2.8 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 165 °C |

| Inert gas | Argon |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 60 µm |

| Volume Rate | up to 4 x 10.5 mm³/s |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with DIN EN 1706 (EN AC—43000) and ASTM F3318-18 standards.

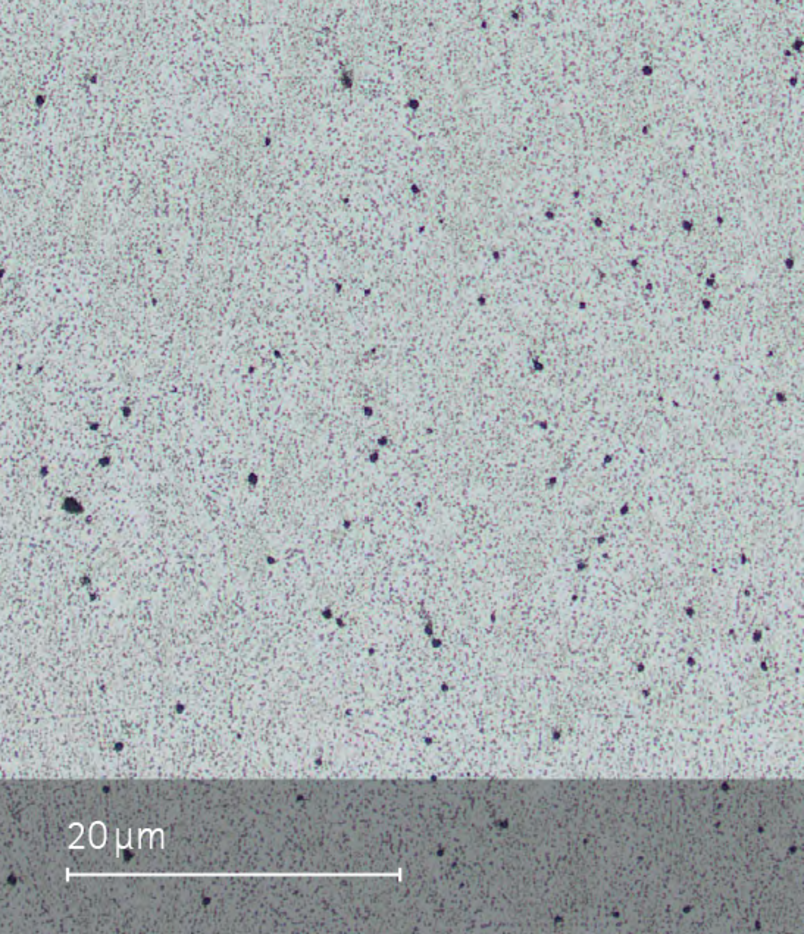

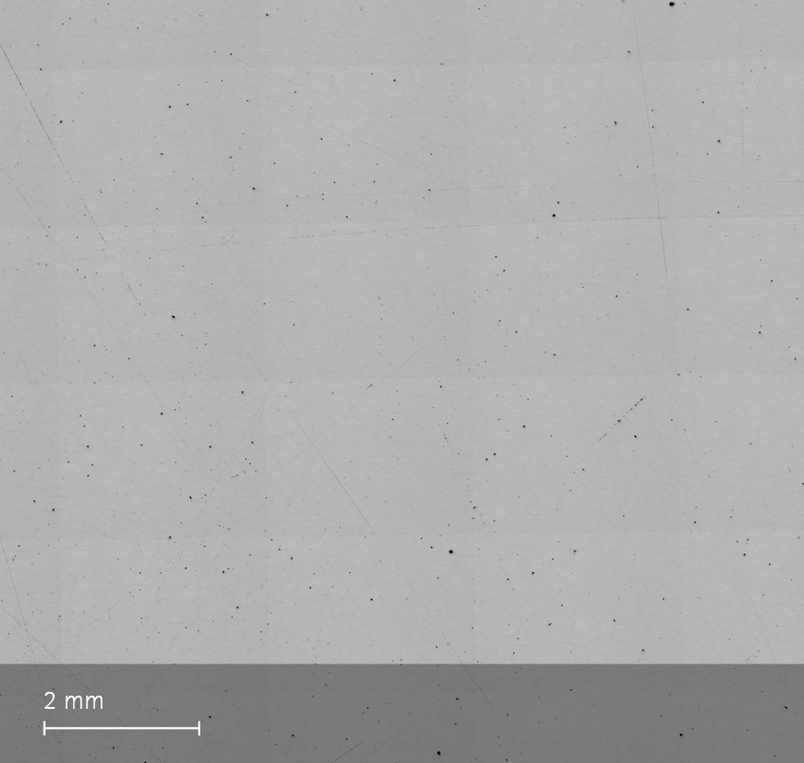

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 60 µm | 0.08 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 250 | 320 | 11 | - | - | - |

| Horizontal | 260 | 330 | 11 | - | - | - |

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40 % shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment).

An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing:

30 minutes in 530 °C followed by immediate quenching to water.

Aging:

Artificial aging of 6 hours in 165 °C followed by cooling in air.

In case higher build platform temperature is used it is strongly advised to perform EOS T6 heat treatment in order to obtain mechanical properties similar to those stated in the MDS.

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 210 | 400 | 4 | - | - | - |

| Horizontal | 230 | 370 | 7 | - | - | - |

EOS Aluminium AlSi10Mg for EOS M 400-1 | 90 µm

EOS M 400 - 90 µm - TRL 3

Process Information Metal

High productivity process with moderate mechanical properties. EOS T6 heat treatment is recommended for parts where higher elongation properties are required.

Main Characteristics:

→ High productivity

→ Moderate mechanical properties

→ Good buildability with uniform surface roughness

| System Setup | EOS M 400 |

|---|---|

| EOS Material set | AlSi10Mg_090_FlexM400 |

| Software Requirements |

EOSPRINT 2.6 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 165 °C |

| Nozzle | Standard |

| Inert gas | Nitrogen |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 90 µm |

| Volume Rate | 27.8 mm³/s |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with DIN EN 1706 (EN AC—43000) and ASTM F3318-18 standards.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 90 µm | 0.2 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 230 | 300 | 5 | - | - | - |

| Horizontal | 230 | 310 | 5 | - | - | - |

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40 % shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment).

An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing:

30 minutes in 530 °C followed by immediate quenching to water.

Aging:

Artificial aging of 6 hours in 165 °C followed by cooling in air.

In case higher build platform temperature is used it is strongly advised to perform EOS T6 heat treatment in order to obtain mechanical properties similar to those stated in the MDS.

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 240 | 380 | 2 | - | - | - |

| Horizontal | 260 | 400 | 3 | - | - | - |

EOS Aluminium AlSi10Mg for EOS M 400-4 | 30 µm

EOS M 400-4 - 30 µm - TRL 3

Process Information Metal

Earlier generation AlSi10Mg M400-4 process.

One-sided recoating enables optimizing powder usage in larger parts.

EOS T6 heat treatment is recommended for parts where higher elongation properties are required.

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | AlSi10Mg_030_FlexM404 |

| Software Requirements |

EOSPRINT 2.6 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 165 °C |

| Inert gas | Nitrogen |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 30 µm |

| Volume Rate | up to 4 x 7.4 mm³/s |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with DIN EN 1706 (EN AC—43000) and ASTM F3318-18 standards.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 30 µm | 0.15 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

Mechanical Properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 230 | 430 | 3 | - | - | - |

| Horizontal | 250 | 400 | 5 | - | - | - |

EOS Aluminium AlSi10Mg for EOS M 400-4 | 40 µm

EOS M 400-4 - 40 µm - TRL 5

Process Information Metal

High performance process with optimized quality and productivity. Good buildability with low surface

roughness. EOS T6 heat treatment is recommended for parts where higher elongation properties are required.

Main Characteristics:

→ High performance AlSi10Mg process for EOS M 400-4

→ Optimized combination of mechanical properties and productivity

→ Two-sided recoating reduces building time

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | AlSi10MgAr_040_CoreM404 |

| Software Requirements |

EOSPRINT 2.7 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 35 °C |

| Nozzle | Standard |

| Inert gas | Argon |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | up to 4 x 7 mm³/s |

| Wall Thickness | 0.3 mm |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with the DIN EN 1706 (EN AC—43000) standard.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | < 0.1 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 230 | 300 | 10 | - | - | - |

| Horizontal | 250 | 310 | 10 | - | - | - |

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40 % shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment).

An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing:

30 minutes in 530 °C followed by immediate quenching to water.

Aging:

Artificial aging of 6 hours in 165 °C followed by cooling in air.

In case higher build platform temperature is used it is strongly advised to perform EOS T6 heat treatment in order to obtain mechanical properties similar to those stated in the MDS.

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 230 | 450 | 5 | - | - | - |

| Horizontal | 250 | 440 | 8 | - | - | - |

Fatigue

| As Manufactured | |

|---|---|

| Fatigue strength [MPa] | 110 |

Method: HCF, ASTM E466-15, 10 million cycles, fully reversed

Aluminum alloys do not have fatigue limit. Actual fatigue values depend on sample geometry and specially surface finish. EOS uses machined (turned) samples in determining material properties. Typically EOS T6 heat treatment does not have significant effect on fatigue strength.

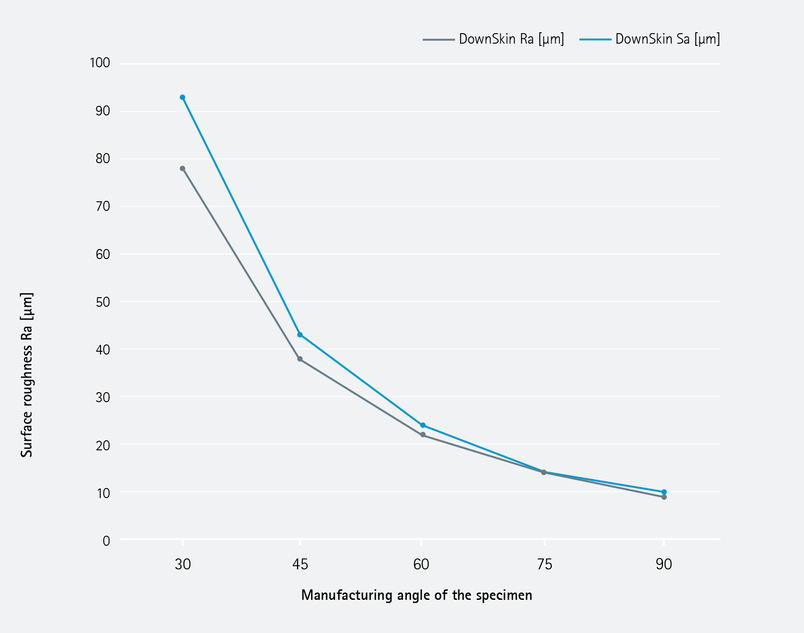

Surface Roughness

EOS Aluminium AlSi10Mg for EOS M 400-4 | 80 µm

EOS M 400-4 - 80 µm - TRL 5

Process Information Metal

This process parameter is developed specifically for fast and cost-efficient production of aluminum

parts with similar mechanical properties as conventionally produced casting parts. EOS T6 heat treatment is recommended for parts where higher elongation properties are required.

Main Characteristics:

→ Highest productivity of aluminum parts on the EOS M 400-4: Up to 261 cm3/h build rate

→ Excellent buildability for challenging parts

→ Two different parameter set options available for surface exposure

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | AlSi10Mg_080_HiProM404 |

| Software Requirements |

EOSPRINT 2.6 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 165 °C |

| Nozzle | Standard |

| Inert gas | Nitrogen |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 80 µm |

| Volume Rate | up to 4 x 18.1 mm³/s |

| Wall Thickness | 0.4 mm |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with DIN EN 1706 (EN AC—43000) and ASTM F3318-18 standards.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 80 µm | 0.5 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 210 | 300 | 6 | - | - | - |

| Horizontal | 220 | 310 | 8 | - | - | - |

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40 % shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment).

An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing:

30 minutes in 530 °C followed by immediate quenching to water.

Aging:

Artificial aging of 6 hours in 165 °C followed by cooling in air.

In case higher build platform temperature is used it is strongly advised to perform EOS T6 heat treatment in order to obtain mechanical properties similar to those stated in the MDS.

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 220 | 360 | 2 | - | - | - |

| Horizontal | 250 | 380 | 2 | - | - | - |

EOS Aluminium AlSi10Mg for EOS M 300-4 1kW | 80 μm

EOS M 300-4 1kW - 80 µm - TRL 3

Process Information Metal

1kW process with very high build rate to meet casting requirements. Low angle buildability and new supporting strategy enable low effort post processing.

Main Characteristics:

→ High productivity process with 1kW-laser

→ Buildability up to 20° angle

→ Easier to remove support strategy

→ Reduction in post processing

→ Good surface roughness

Typical applications:

→ General engineering components and parts subject to high loads

→ Casting parts

| System Setup | EOS M 300-4 1kW |

|---|---|

| EOS Material set | AlSi10Mg_080_HiProM314 |

| Required Software Plan | EOS BUILD |

| Software Requirements |

EOSPRINT 2.16 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 165 °C |

| Inert gas | Argon |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 80 µm |

| Volume Rate | up to 4 x 36 mm³/s |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with DIN EN 1706 (EN AC—43000) and ASTM F3318-18 standards.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 80 µm | 0.35 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 230 | 300 | 10 | - | - | - |

| Horizontal | 240 | 310 | 11 | - | - | - |

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40 % shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment).

An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing:

30 minutes in 530 °C followed by immediate quenching to water.

Aging:

Artificial aging of 6 hours in 165 °C followed by cooling in air.

In case higher build platform temperature is used it is strongly advised to perform EOS T6 heat treatment in order to obtain mechanical properties similar to those stated in the MDS.

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 150 | 290 | 5 | - | - | - |

| Horizontal | 140 | 240 | 9 | - | - | - |

Hardness

| EN ISO 6506 As Manufactured | |

|---|---|

| Value | 80 |

| Unit | HBS 1/10 |

| EN ISO 6506 Heat Treated | |

|---|---|

| Value | 95 |

| Unit | HBS 1/10 |

Surface Roughness

EOS Aluminium AlSi10Mg for EOS M 290 1kW | 80 μm

EOS M 290 1kW - 80 µm - TRL 3

Process Information Metal

1kW process with very high build rate to meet casting requirements. Low angle buildability and new supporting strategy enable low effort post processing.

Main Characteristics:

→ High productivity process with 1kW-Laser

→ Buildability up to 20° angle

→ Easier to remove support strategy

→ Reduction in post processing

→ Good surface roughness

| System Setup | EOS M 290 1kW |

|---|---|

| EOS Material set | AlSi10Mg_080_HiProM294 |

| Required Software Plan | EOS BUILD |

| Software Requirements |

EOSPRINT 2.16 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 125 °C |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 80 µm |

| Volume Rate | up to 36 mm³/s |

Chemical and Physical Properties of Parts

The chemical composition of the EOS Aluminium AlSi10Mg parts is in compliance with DIN EN 1706 (EN AC—43000) and ASTM F3318-18 standards.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 80 µm | 0.6 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 240 | 310 | 7 | - | - | - |

| Horizontal | 250 | 320 | 7 | - | - | - |

EOS T6 Heat Treatment

EOS has developed an AM optimized heat treatment procedure that is 40 % shorter than conventional T6 heat treatment procedures.

Solution annealing 30 min @ 530 °C, water quench. Artificial aging 6 h @ 165 °C, cooling in air. Parts to preheated oven. Maximum overheating 5 °C. Delay between SA and quenching maximum 30 s. Oven type & configuration may have impact on the mechanical properties. For complex and massive parts uniform heating and cooling needs to be arranged.

EOS T6 treatment is recommended to obtain controlled mechanical properties and lower variation in mechanical values (for example in long build jobs if heat transfer from parts is limited by low amount of support and after stress relief heat treatment).

An increase in porosity due to heat treatment is possible. A more detailed description of heat treatment is available upon request.

Solution Annealing:

30 minutes in 530 °C followed by immediate quenching to water.

Aging:

Artificial aging of 6 hours in 165 °C followed by cooling in air.

In case higher build platform temperature is used it is strongly advised to perform EOS T6 heat treatment in order to obtain mechanical properties similar to those stated in the MDS.

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 220 | 360 | 2 | - | - | - |

| Horizontal | 220 | 370 | 3 | - | - | - |

Hardness

| EN ISO 6506 As Manufactured | |

|---|---|

| Value | 110 |

| Unit | HB 1/10 |

Surface Roughness