EOS StainlessSteel 17-4PH

Material Data Sheet

EOS StainlessSteel 17-4PH

Precipitation hardening steels are widely used in engineering applications, which require corrosion resistance and strength. Parts built from EOS StainlessSteel 17-4PH can be machined, shot-peened and polished in as-built or heat treated states. Solution annealing together with ageing treatment are necessary in order to achieve proper hardness and mechanical properties (ASTM A564 – 13). Due to the layerwise building method, the parts have a certain anisotropy which can be eased by solution annealing.

- Corrosion resistance and strength

- Parts can be machined, shot-peened and polished in asbuilt or heat treated states

- Solution annealing together with aging treatment are necessary in order to achieve proper hardness and mechanical properties (ASTM A564-13)

- Chemical composition and part properties corresponding to 1.4542, UNS 17400 and ASTM A564M

- Acid and corrosion resistant engineering parts

- Medical instruments (surgical tools, orthopedic instrumentation)

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

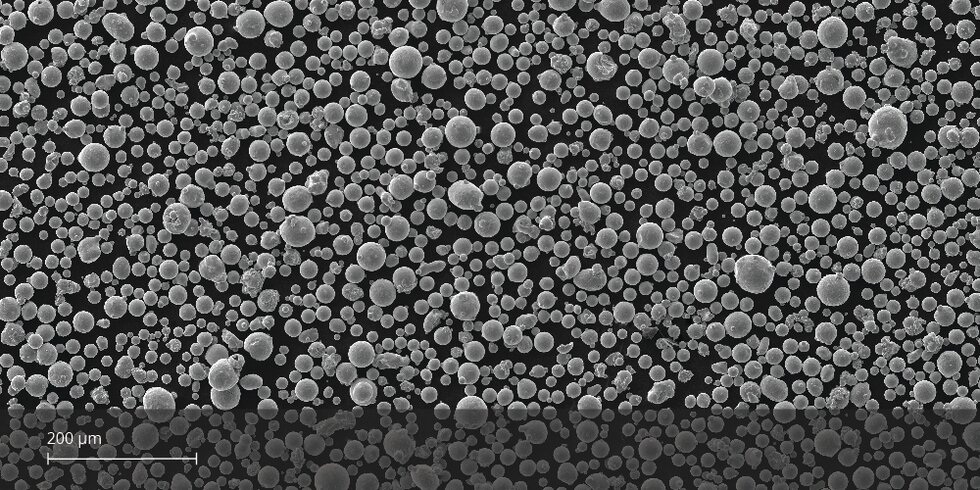

POWDER PROPERTIES

The chemical composition of parts is in compliance with standards “F899 – 12b Standard Specification for Wrought Stainless Steels for Surgical Instruments” and “A564M – 13 Standard Specification for Hot-Rolled and Cold-Finished AgeHardening Stainless Steel Bars and Shapes”. Composition complies the material composition in “powder properties” section. Part accuracy is adjustable by changing the “Beam Offset, X-, Y- and Z-Shrinkage”-parameters.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Cr | 15.0 | 17.5 |

| Ni | 3.0 | 5.0 |

| Cu | 3.0 | 5.0 |

| Si | 0.0 | 1.0 |

| Mn | 0.0 | 1.0 |

| C | 0.0 | 0.07 |

| P | 0.0 | 0.04 |

| S | 0.0 | 0.03 |

| Nb + Ta | 0.15 | 0.45 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 65 μm | |

|---|---|---|

HEAT TREATMENT

Vacuum H900 & Atmospheric HT procedures

Vacuum H900 heat treatment procedure

Solution annealing: Hold at 1040°C (1904°F) ±15°C (± 59°F) for 30 minutes, air cooling under 32°C (89°F).

Ageing: Hold at 480°C (896°F) for one hour, air cooling under 32°C (89°F).

Atmospheric HT procedure (preferred atmosphere: Argon)

Solution annealing: Hold at 1040°C (1904°F) ±15°C (± 59°F) for 30 minutes, air cooling under 32°C (89°F).

Ageing: Hold at 460°C (860°F) for one hour, air cooling under 32°C (89°F).

EOS StainlessSteel 17-4PH for EOS M 290 | 40/80 µm

EOS M 290 - 40 µm - TRL 3

Process Information Metal

This process product is optimized for flexible and fast production of 17-4PH parts with EOS M 290 system. The parameter set has three different layer thickness options that can all be utilized within the same build: 40µm, 80 µm and 40/80 µm Skin. For high productivity needs a 80 µm parameter set is included with a build rate more than double the long established 40 µm parameter set. Both can be used separately for different parts or combined by using 40/80 µm Skin with faster 80 µm for the core of the part and higher quality 40 µm building for the surface of the part with defined thickness. Sectionioning parts in vertical direction for different parameters is also possible.

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | 17-4PH_040_080_Core M291 |

| Required Software Plan | EOS BUILD |

| Software Requirements |

EOSPRINT 2.14 or newer |

| Recoater Blade | Ceramic |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40/80 µm |

| Volume Rate | 4.1-7.9 mm³/s |

| Typical Dimensional Change after HT [%] | +0.2 % |

Chemical and Physical Properties of Parts

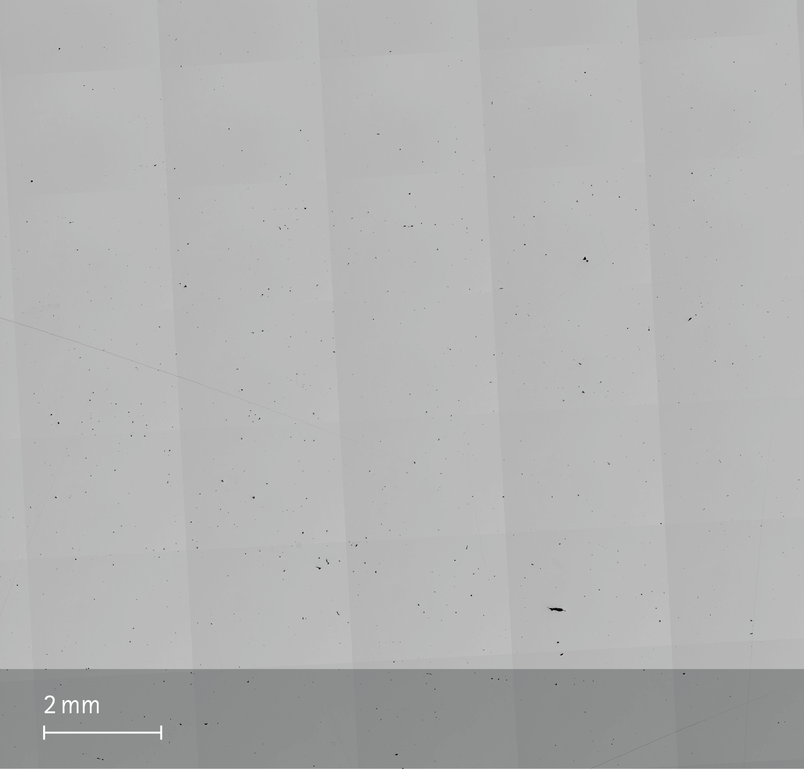

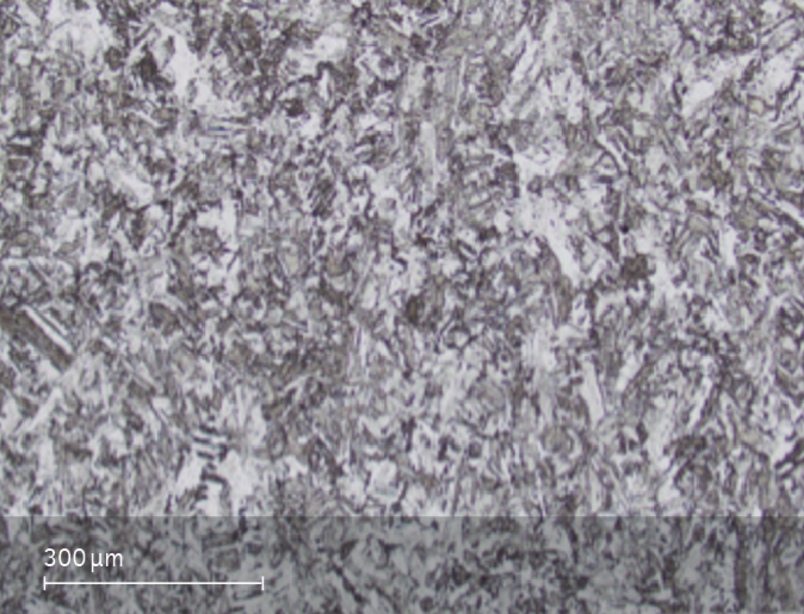

Etched micrograph of powder

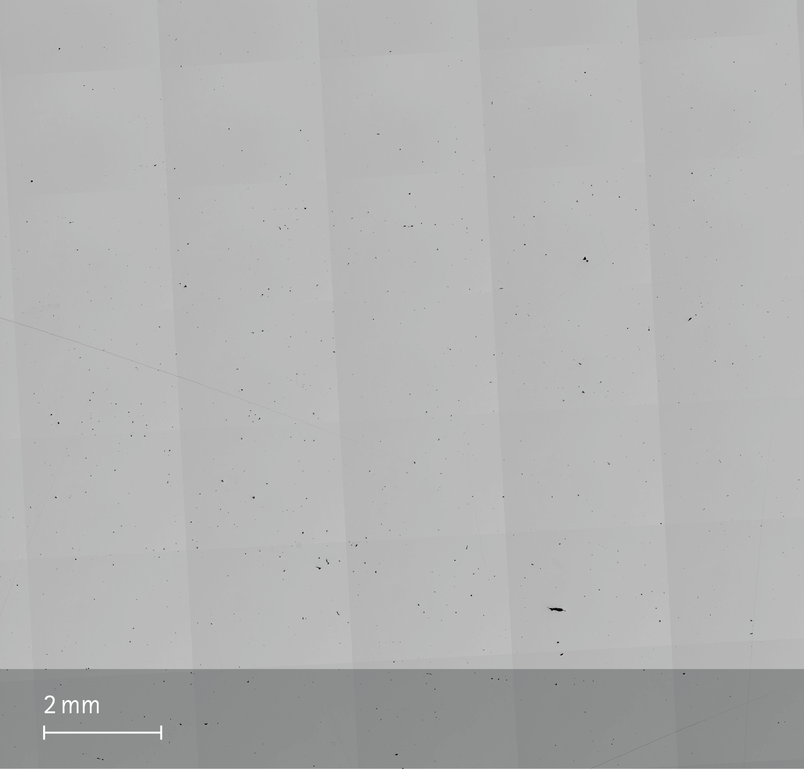

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | <0.1 % | - |

| Average Defect Percentage | 80 µm | <0.2 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 1240 | 1360 | 14 | - | - | - |

| Horizontal | 1240 | 1360 | 14 | - | - | - |

H900 Heat treatment

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 1240 | 1360 | 13 | - | - | - |

| Horizontal | 1230 | 1355 | 14 | - | - | - |

H900 Heat treatment

Impact Toughness

| EN ISO 148-1, Charpy-V Heat Treated | |

|---|---|

| Typical Impact Toughness [J] | 20 |

| Layer Thickness | 40 µm |

H900 Heat treatment

| Heat Treated | |

|---|---|

| Typical Impact Toughness [J] | 20 |

| Layer Thickness | 80 µm |

H900 Heat treatment

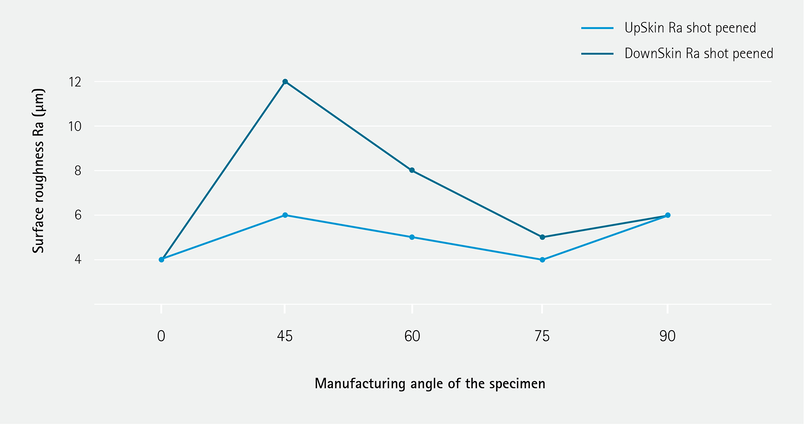

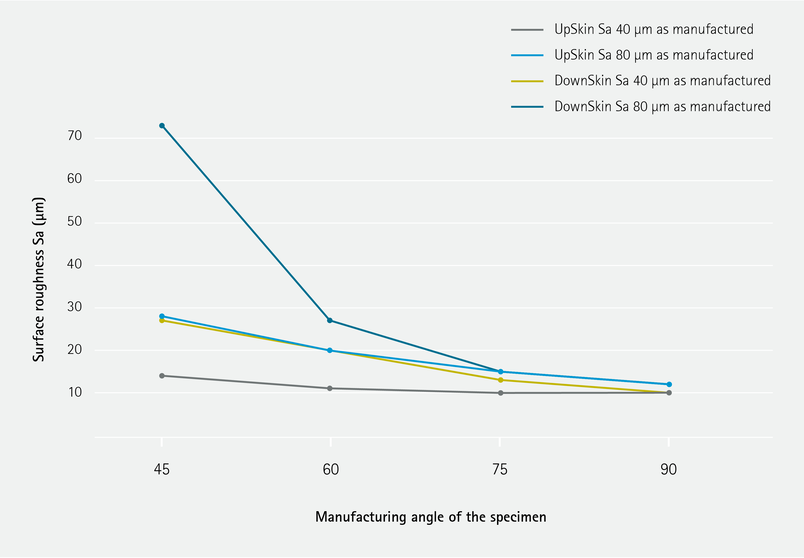

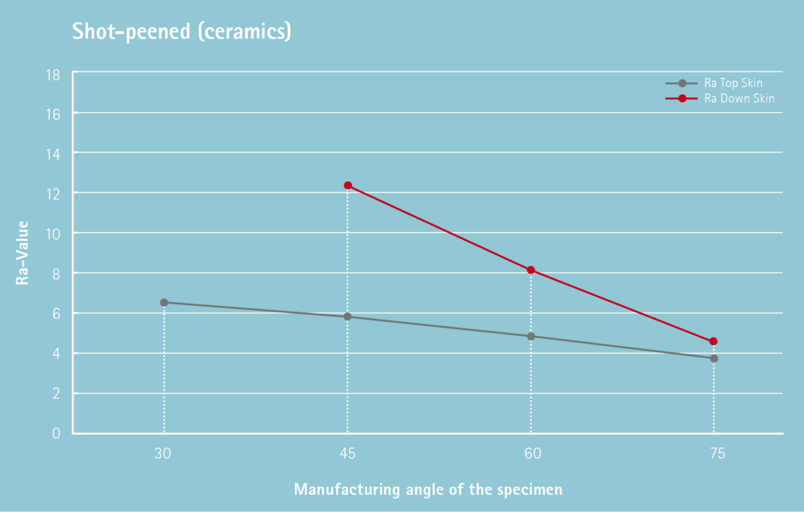

Surface Roughness

EOS StainlessSteel 17-4PH on EOS M 400-4 | 40/80 µm

EOS M 400-4 - 40 µm - TRL 3

Process Information Metal

This process product is optimized for flexible and fast production of 17-4PH parts with M 400-4 system. The parameter set has three different layer thickness options that can all be utilized within the same build: 40µm, 80 µm and 40/80 µm Skin. For high productivity needs a 80 µm parameter set is included with a build rate more than double the long established 40 µm parameter set. Both can be used separately for different parts or combined by using 40/80 µm Skin with faster 80 µm for the core of the part and higher quality 40 µm building for the surface of the part with defined thickness. Sectionioning parts in vertical direction for different parameters is also possible.

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | 17-4PH_040_080_Core M404 |

| Required Software Plan | EOS BUILD |

| Software Requirements |

EOSPRINT 2.14 or newer |

| Recoater Blade | Ceramic |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40/80 µm |

| Volume Rate | 4.1 -7.9 mm³/s |

| Typical Dimensional Change after HT [%] | +0.2 % |

Chemical and Physical Properties of Parts

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | <0.1 % | - |

| Average Defect Percentage | 80 µm | <0.2 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 1245 | 1350 | 13 | - | - | - |

| Horizontal | 1240 | 1360 | 13 | - | - | - |

H900 Heat treatment

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 1190 | 1350 | 14 | - | - | - |

| Horizontal | 1180 | 1360 | 14 | - | - | - |

H900 Heat treatment

Impact Toughness

| EN ISO 148-1, Charpy-V Heat Treated | |

|---|---|

| Typical Impact Toughness [J] | 20 |

| Layer Thickness | 40 µm |

H900 Heat treatment

| Heat Treated | |

|---|---|

| Typical Impact Toughness [J] | 20 |

| Layer Thickness | 80 µm |

H900 Heat treatment

Surface Roughness

EOS StainlessSteel 17-4PH for EOS M 290 | 40 µm

EOS M 290 - 40 µm - TRL 7

Process Information Metal

This process product is optimized for flexible and reliable production of 17-4PH parts with emphasis on quality.

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | 17-4PH_040_StainlessM291 |

| Software Requirements |

EOSPRINT 1.5 or newer |

| Recoater Blade | Ceramic |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | 3.3 mm³/s |

| Typical Dimensional Change after HT [%] | +0.2 % |

Chemical and Physical Properties of Parts

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | - | 0.03 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 1250 | 1340 | 13.5 | - | - | - |

| Horizontal | 1235 | 1335 | 14 | - | - | - |

H900 Heat treatment

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 860 | 920 | 20 | - | - | - |

| Horizontal | 890 | 860 | 20 | - | - | - |

Hardness

| EN ISO 6508 Heat Treated | |

|---|---|

| Value | 42 |

| Unit | HRC |

| EN ISO 6508 As Manufactured | |

|---|---|

| Value | 24 |

| Unit | HRC |

Surface Roughness

EOS StainlessSteel 17-4PH for EOS M 300-4 | 40 µm

EOS M 300-4 - 40 µm - TRL 3

| System Setup | EOS M 300-4 |

|---|---|

| EOS Material set | 17-4PH_040_CoreM304 |

| Software Requirements |

EOSPRINT 2.11 or newer |

| Recoater Blade | Ceramic |

| Build Platform Temperature | 80 °C |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | up to 4 x 3.32 mm³/s |

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | - | 0.014 % | - |

Mechanical Properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 947 | 1052 | 15.7 | - | - | - |

| Horizontal | 941 | 1015 | 16.8 | - | - | - |

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 1240 | 1371 | 10.5 | - | - | - |

| Horizontal | 1207 | 1349 | 10.7 | - | - | - |