EOS Titanium Ti64

Material Data Sheet

EOS Titanium Ti64

EOS Titanium Ti64 has a chemical composition corresponding to ASTM F1472 and ASTM F2924. Ti64 is well-known light alloy, characterized by having excellent mechanical properties and corrosion resistance combined with low specific weight. Ti64 material is ideal for many high performance applications. Parts built with EOS Titanium Ti64 powder can be machined, shot-peened and polished in as-built and heat treated states. Due to the layerwise building method, the parts have a certain anisotropy.

- Excellent mechanical properties and corrosion resistance

- Low weight & biocompatibility

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

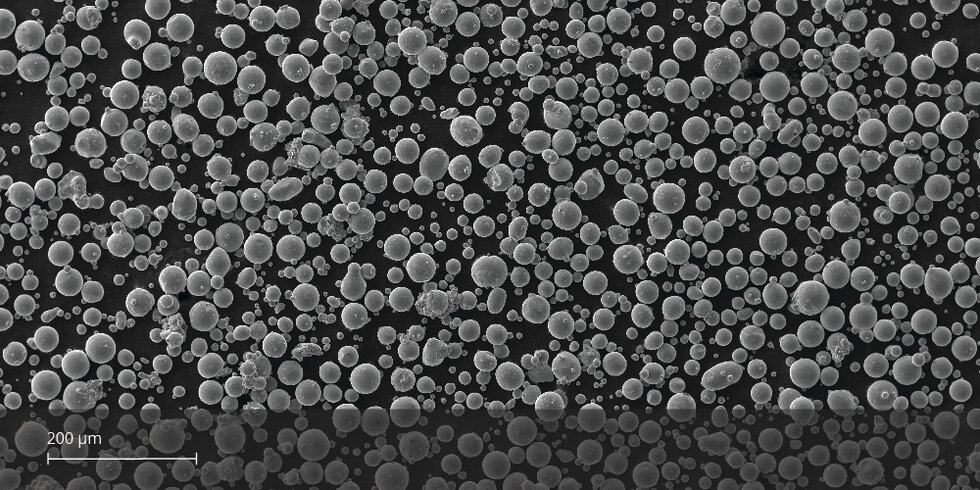

POWDER PROPERTIES

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Al | 5.5 | 6.75 |

| V | 3.5 | 4.5 |

| O | - | 0.2 |

| N | - | 0.05 |

| C | - | 0.08 |

| H | - | 0.015 |

| Fe | - | 0.3 |

| Y | - | 0.005 |

| Other Elements Each | - | 0.1 |

| Other Elements Total | - | 0.4 |

| Ti | Balance | |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 25 - 55 μm | |

|---|---|---|

HEAT TREATMENT

2 hours at 800ºC in Argon atmosphere.

EOS Titanium Ti64 for EOS M4 ONYX | 60 µm

EOS M4 ONYX - 60 µm

Process Information Metal

The M 4 ONYX Ti64 60 µm process combines significant productivity gains, excellent surface finish, and exceptional cleanliness, making it ideal for demanding titanium applications.

Key innovations include optimized scanning strategies and exposure techniques that dramatically reduce non-productive movements, enabling faster builds with outstanding quality.

Please note that the following data is a preview. Additional statistics and detailed insights will be published shortly.

Highlights:

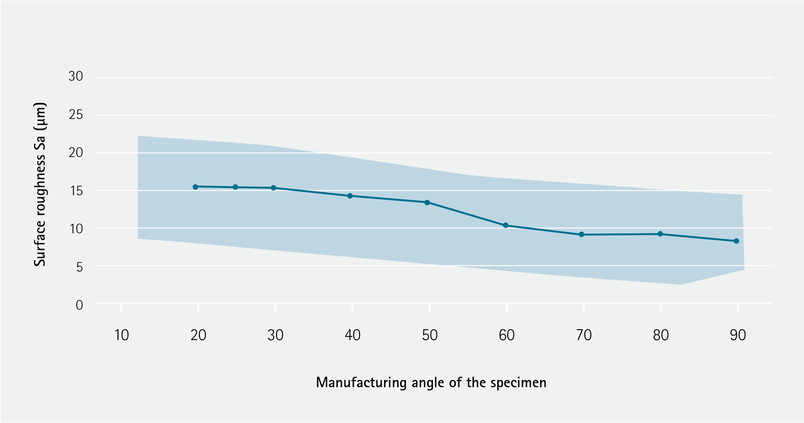

- Outstanding surface quality: Sa values < 15 µm down to 25°.

- Improved buildability: Down to 20°/25° without support.

| System Setup | EOS M4 ONYX |

|---|---|

| Required Software Plan | EOS BUILD |

| Recoater Blade | HSS (High Speed Steel) |

| Inert gas | Argon |

| Sieve | 63 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 60 µm |

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 60 µm | < 0.01 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 1075 | 1140 | 14 | - | - | - |

| Horizontal | 1035 | 1020 | 11 | - | - | - |

2h @ 800°C in vacuum

Surface Roughness