EOS ToolSteel H13

Material Data Sheet

EOS ToolSteel H13

High strength tool steel for hot and cold work tooling applications

EOS ToolSteel H13 is a versatile high strength tool steel for hot and cold work tooling applications. The high toughness and excellent thermal properties of H13 make it one of the most used material in hot work tooling. EOS ToolSteel H13 provides excellent properties to successfully bring AM into use for die casting production.

- Chemical composition is similar to ASTM A681-08

- Excellent toughness and ductility

- Good high temperature strength

- High hot wear resistance

- Die cast tooling

- Forging

- Hot extrusion tools

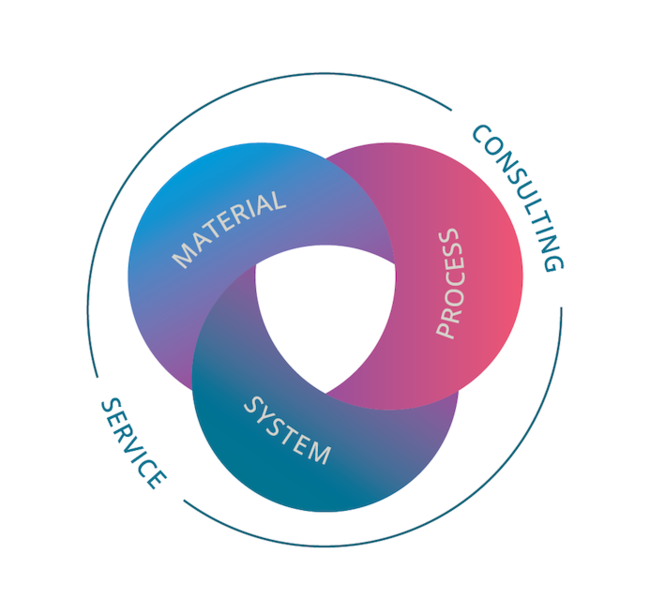

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

EOS ToolSteel H13 powder chemistry is according to ASTM A681-08.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Fe | Balance | |

| Cr | 4.75 | 5.5 |

| Mo | 1.1 | 1.75 |

| Si | 0.8 | 1.25 |

| V | 0.8 | 1.2 |

| Mn | 0.2 | 0.6 |

| C | 0.32 | 0.45 |

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 63 μm | |

|---|---|---|

HEAT TREATMENT

EOS ToolSteel H13 can be heat treated to various hardness levels to match the needs of different applications. Heat treatment consists of three stages. First stage is a soft annealing process to relieve stresses form the built part. This treatment is to performed for parts on the building platform. After soft annealing parts can be removed from the building platform and needed post processing and hardening heat treatment can be applied.

1. Soft annealing

Heating with moderate heating rate and then hold 30 min at 850 °C (±10 °C) when parts have thoroughly heated through. Next cool slowly to 650 °C with a cooling rate of 10 °C/ hour. After reaching 650 °C cooling in air or with low pressure gas cooling.

2. Hardening

Heating with moderate heating rate and then hold 30 min at 1 045 °C (±10 °C) when parts have thoroughly heated through. Quench the parts with high speed gas cooling or warm oil. Optimally continue directly to tempering when reaching 50-70 °C.

3. Tempering

2 times 2 h at 580-650 °C depending on the desired hardness level.

Hold for 2 h at desired temperature when parts have thoroughly heated through. Cool to room temperature between temperings.

EOS ToolSteel H13 for EOS M 290 | 40 µm

EOS M 290 - 40 µm - TRL 3

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | H13_040_CoreM291 |

| Software Requirements |

EOSPRINT 2.6.21 or newer |

| Recoater Blade | Ceramic |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon, Nitrogen |

| Sieve | 90 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | 3.7 mm³/s |

Chemical and Physical Properties of Parts

Chemical composition of built parts matches the chemistry of EOS ToolSteel H13 powder.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | 0.08 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Number of Samples | |

|---|---|---|---|---|---|---|

| Vertical | 1490 | 1680 | 9 | - | - | - |

| Horizontal | 1480 | 1670 | 9 | - | - | - |

Heat treated to 50 HRC

EOS ToolSteel H13 can be heat treated to various hardness levels to match the needs of different applications. Heat treatment consists of three stages. First stage is a soft annealing process to relieve stresses form the built part. This treatment is to performed for parts on the building platform. After soft annealing parts can be removed from the building platform and needed post processing and hardening heat treatment can be applied.

1. Soft annealing

Heating with moderate heating rate and then hold 30 min at 850 °C (±10 °C) when parts have thoroughly heated through. Next cool slowly to 650 °C with a cooling rate of 10 °C/ hour. After reaching 650 °C cooling in air or with low pressure gas cooling.

2. Hardening

Heating with moderate heating rate and then hold 30 min at 1 045 °C (±10 °C) when parts have thoroughly heated through. Quench the parts with high speed gas cooling or warm oil. Optimally continue directly to tempering when reaching 50-70 °C.

3. Tempering

2 times 2 h at 580-650 °C depending on the desired hardness level.

Hold for 2 h at desired temperature when parts have thoroughly heated through. Cool to room temperature between temperings.

Please note:

Due to high stress build up consideration on part size and shape is needed. Parts with 150 mm cross-section can be reliably built with good design principles and when instructions are followed.

Multiple smaller parts can be built on the same platform. To control temperature a 10 mm perforated hatch support is to be applied for each part unless when building a hybrid part on H13 base. For hybrid parts, size of the H13 base needs consideration due to limited heating capacity of hardware.

A soft annealing heat treatment (stage 1) is to be applied to parts on building platform before any manipulation, post processing or removal from platform.

After soft annealing parts can be heat hardened and tempered according to instructions and post processed as conventional H13 parts.

Surface Roughness

Coefficient of Thermal Expansion

| ASTM E228 | Temperature |

|---|---|

| 11.3*10-6/K | 25 – 100 ºC |

| 11.7*10-6/K | 25 – 200 ºC |

| 12.1*10-6/K | 25 – 300 ºC |

| 12.5*10-6/K | 25 – 400 ºC |

| 12.8*10-6/K | 25 – 500 ºC |

| 13*10-6/K | 25 – 600 ºC |