Process Data Sheet

EOS Aluminium Al2139 AM for EOS M 400-4 | 50 µm

EOS M 400-4 - 50 µm - TRL 3

Process Information Metal

High performance process with good microstructure and excellent mechanical properties and low anisotropy after heat treatment. Good mechanical properties at elevated temperatures in heat treated condition. Process offers good buildability of small features with soft recoating. Part and support design for high strength aluminium is required.

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | Al2139AM_050_CoreM404 |

| Software Requirements |

EOSPRINT 2.10 or newer EOSYSTEM 2.14 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Build Platform Temperature | 195 °C |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 50 µm |

| Volume Rate | up to 4 x 5.0 mm³/s |

| Wall Thickness | 0.4 mm |

Chemical and Physical Properties of Parts

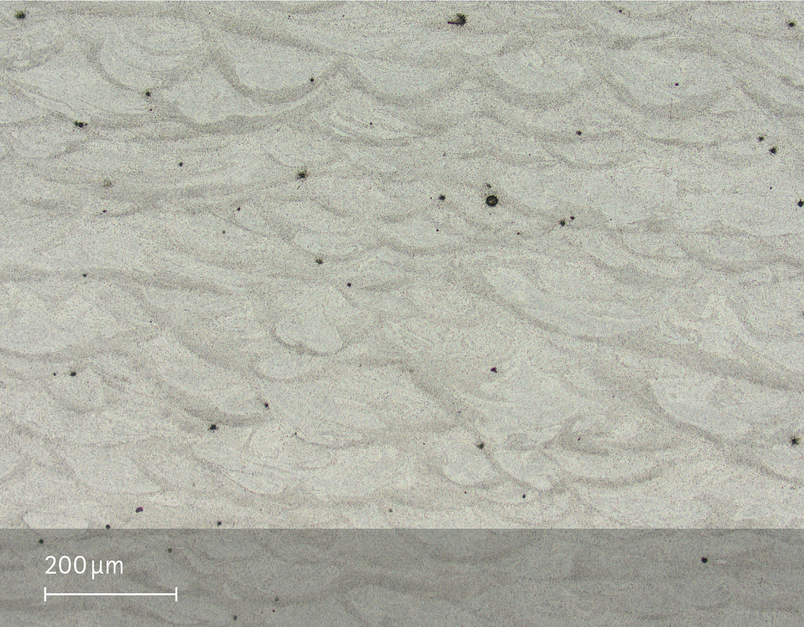

Micrograph etched as manufactured

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 50 µm | 0.1 % | - |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 50 µm | ≥ 2.84 g/cm³ | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | 50 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 450 | 530 | 6 | - | - | - |

| Horizontal | 460 | 550 | 7 | - | - | - |

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | 50 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 380 | 430 | 8 | - | - | - |

| Horizontal | 380 | 430 | 10 | - | - | - |

Hardness

EN ISO 6506-1 Heat Treated |

|

|---|---|

| Value | 168 |

| Unit | HBW 2.5/62.5 |

EN ISO 6506-1 As Manufactured |

|

|---|---|

| Value | 115 |

| Unit | HBW 2.5/62.5 |

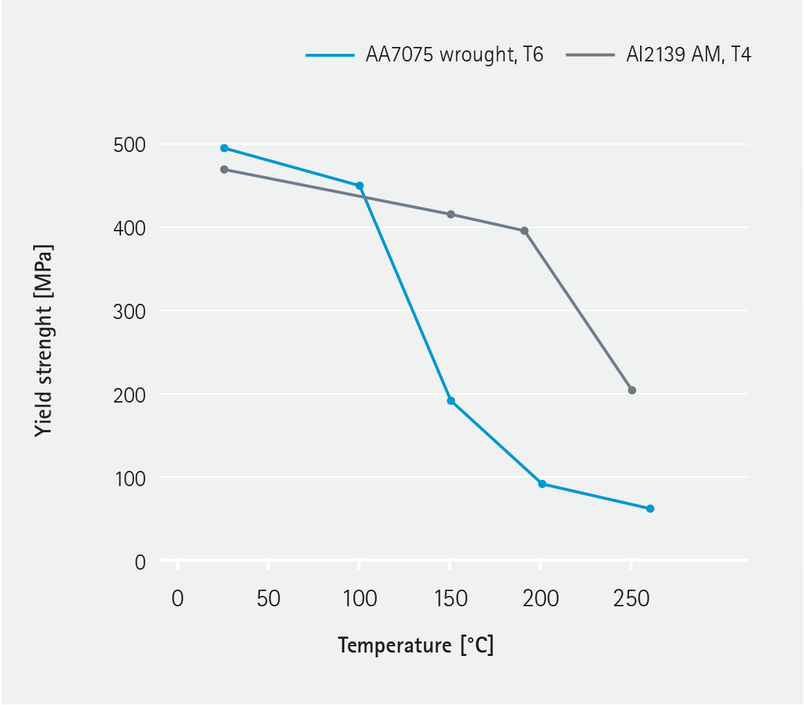

Elevated temperature properties

Elevated temperature properties

Elevated temperature tensile testing of EOS Aluminium

Al2139 AM (T4) and a wrought grade reference material

(T6 HT state) according to EN 2002-002.