Process Data Sheet

EOS Aluminium Al5X1 for EOS M 290 | 40 µm

EOS M 290 - 40 µm - TRL 3

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | Al5X1_040_CoreM291_100 |

| Software Requirements |

EOSPRINT 2.11 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | 4.8 mm³/s |

Chemical and Physical Properties of Parts

The chemical properties of the parts are the same as that of the powder.

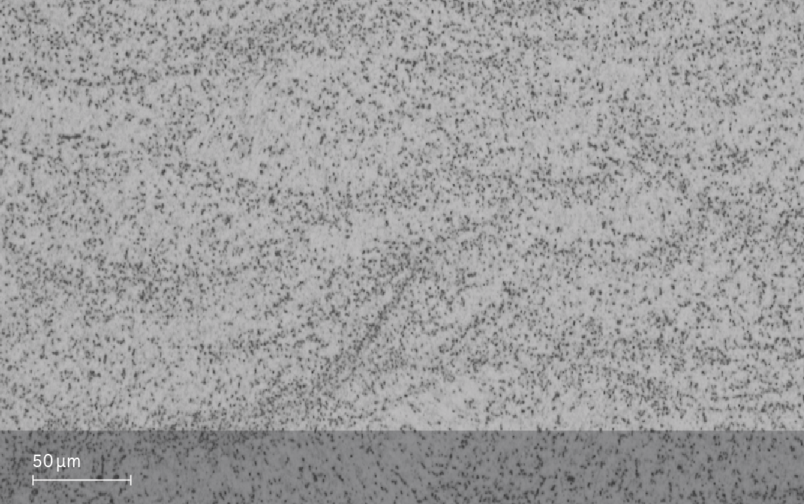

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | 0.15 % | - |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 40 µm | 2.69 g/cm³ | - |

Mechanical Properties

Mechanical Properties Heat Treated

| ASTM E8 Room Temperature | 40 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 380 | 415 | 14.5 | - | - | - |

| Horizontal | 385 | 415 | 14.5 | - | - | - |

ASTM E8, strain rate 0.00762 mm/s

Mechanical Properties As Manufactured

| Room Temperature | 40 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 240 | 310 | 23 | - | - | - |

| Horizontal | 260 | 310 | 23 | - | - | - |

Hardness

| Heat Treated | |

|---|---|

| Value | 127 |

| Unit | HBW 2.5/62.5 |

Brinell

| Heat Treated | |

|---|---|

| Value | 71 |

| Unit | HRB |

Rockwell

| As Manufactured | |

|---|---|

| Value | 86 |

| Unit | HBW 2.5/62.5 |

Brinell

| As Manufactured | |

|---|---|

| Value | 40 |

| Unit | HRB |

Direct aging heat treatment

6 hours at 400 °C. Immediate gas quenching (air cooling

with maximal air flow).

Preferred inert atmosphere during furnace treatment.

Rockwell

Thermal Conductivity

| ASTM E1461-13 | Orientation | [W/m*K] |

|---|---|---|

| Heat Treated | Vertical | 132 |

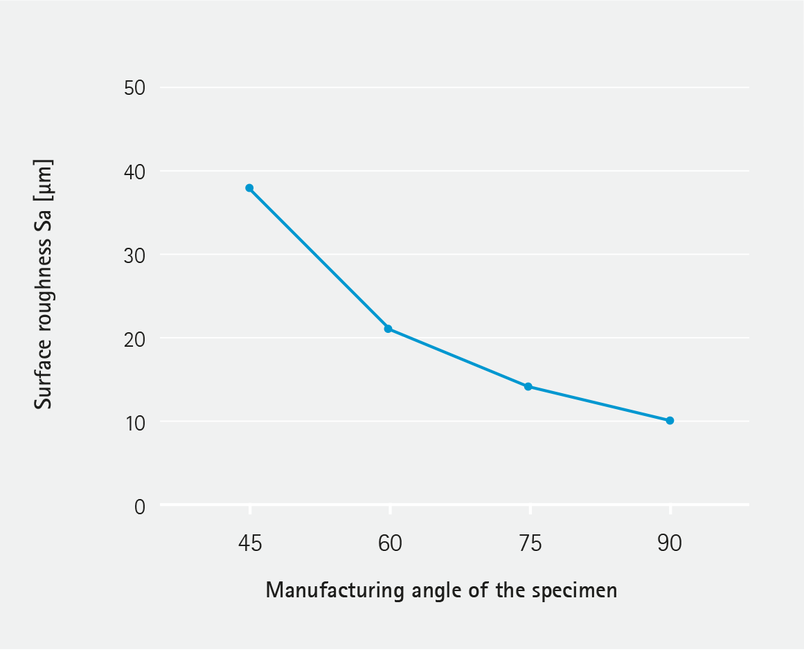

Surface Roughness

Specific heat capacity at 25°C

| AST E1269-11 Heat Treated | |

|---|---|

| Value | 0.87 |

| Unit | J/g/°C |

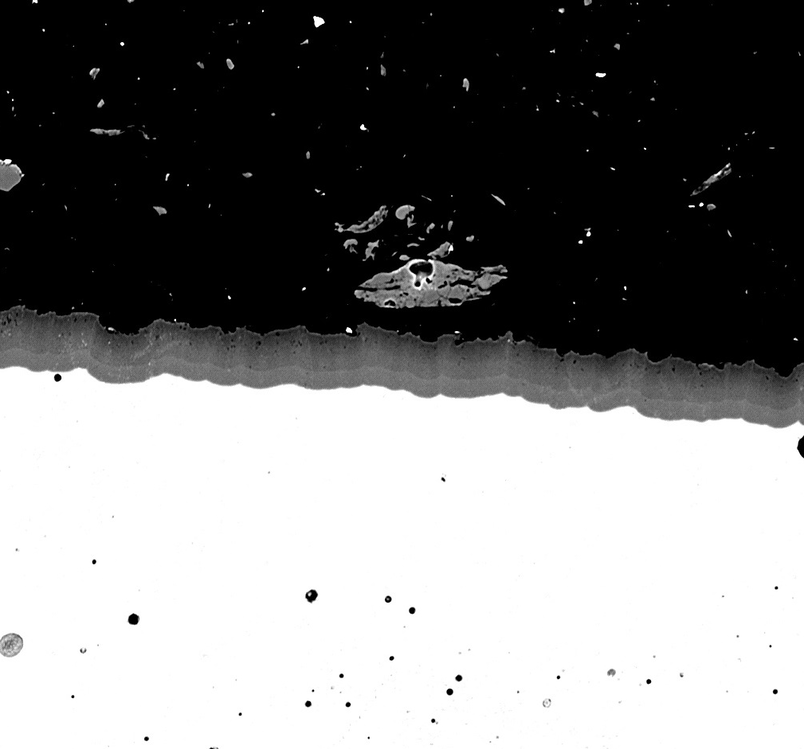

Anodization

SEM image of the anodizing layer.

Anodized according to Mil-A-8625 Type III

Thickness of anodization layer

depends on used anodization

process.

Electrical Conductivity

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| As Manufactured | 40 µm | | Vertical | 23 |

| ASTM E1004-17 | Orientation | Typical Electrical Conductivity [%IACS] |

|---|---|---|

| Heat Treated | 40 µm | | Vertical | 34 |