Process Data Sheet

EOS Aluminium Al2139 AM for EOS M 290 | 60 µm

EOS M 290 - 60 µm - TRL 3

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | Al2139AM_060_CoreM291_110 |

| Software Requirements |

EOSPRINT 2.7 or newer EOSYSTEM 2.11 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 60 µm |

| Volume Rate | 7.2 mm³/s |

| Wall Thickness | 0.4 mm |

Chemical and Physical Properties of Parts

The chemical properties of the parts are the same as that of the powder.

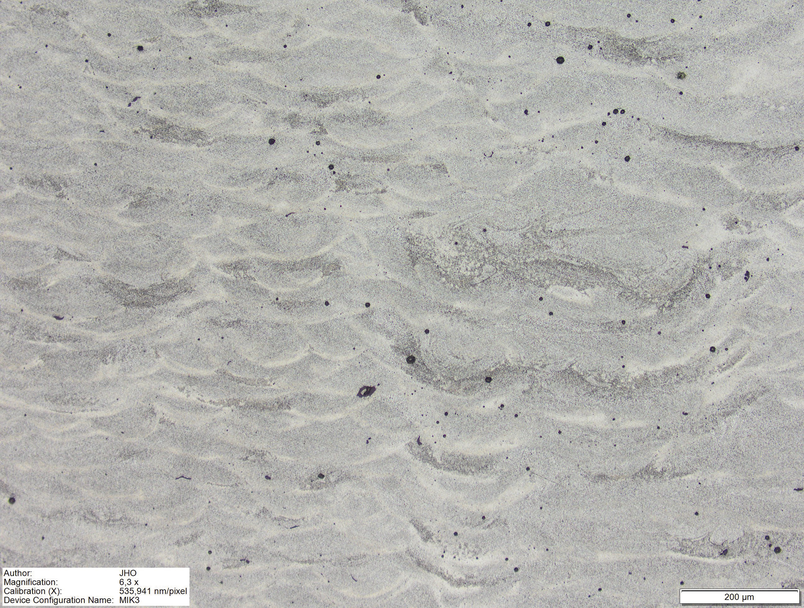

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 60 µm | 0.2-0.3 % | - |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 60 µm | ≥ 2.84 g/cm³ | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 460 | 520 | 4 | - | - |

| Horizontal | 460 | 540 | 6 | - | - |

Mechanical Properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] | Reduction of Area Z [%] | Number of Samples |

|---|---|---|---|---|---|

| Vertical | 350 | 380 | 6 | - | - |

| Horizontal | 350 | 380 | 8 | - | - |

Hardness

| Heat Treated | |

|---|---|

| Value | 162 |

| Unit | HBW 2.5/62.5 |

| As Manufactured | |

|---|---|

| Value | 112 |

| Unit | HBW 2.5/62.5 |

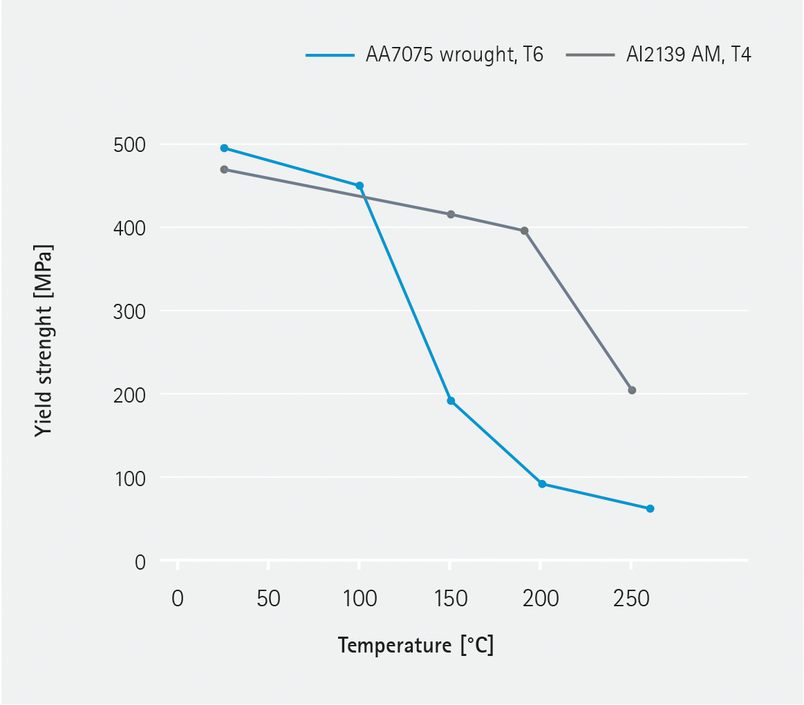

Elevated temperature properties