Process Data Sheet

EOS StainlessSteel 254 for EOS M 290 | 60 µm

EOS M 290 - 60 µm - TRL 3

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | 254_060_CoreM291_100 |

| Software Requirements |

EOSPRINT 2.8 or newer EOSYSTEM 5.20 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 60 µm |

| Volume Rate | 6.1 mm³/s |

Chemical and Physical Properties of Parts

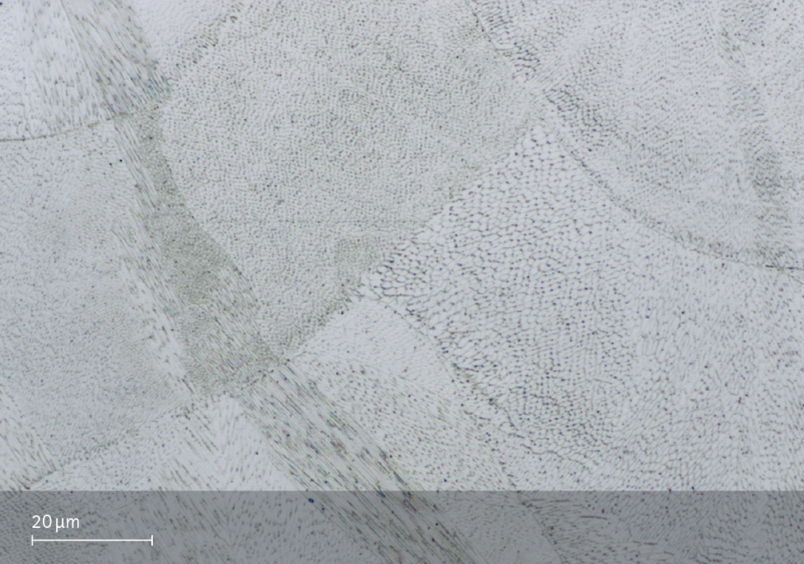

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 60 µm | 0.02 % | - |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 60 µm | ≥ 8.07 g/cm³ | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | 60 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 360 | 660 | 48 | - | - | - |

| Horizontal | 360 | 700 | 44 | - | - | - |

Optional solution annealing

At 1 180 °C for 2 h after parts have fully heated through, water quenching.

Typical dimensional change after heat treatment: 0.06 %

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | 60 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 580 | 730 | 36 | - | - | - |

| Horizontal | 660 | 800 | 30 | - | - | - |

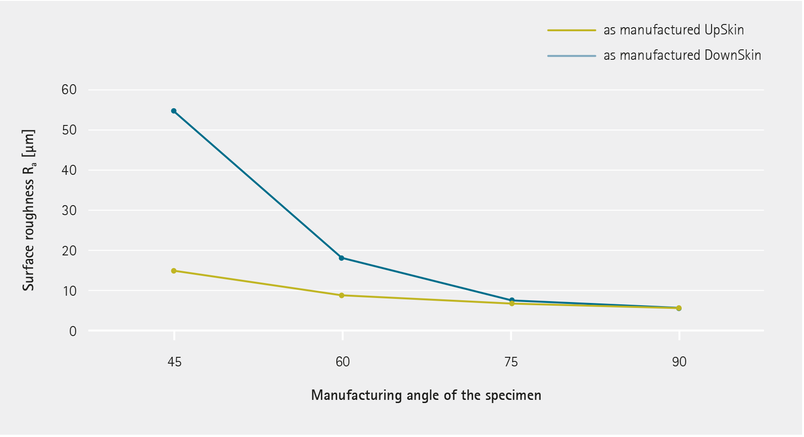

Surface Roughness

Coefficient of Thermal Expansion

| ASTM E228 | Temperature |

|---|---|

| 14.8*10-6/K | 25 – 100 ºC |

| 15.7*10-6/K | 25 – 200 ºC |

| 16.3*10-6/K | 25 – 300 ºC |

| 16.7*10-6/K | 25 – 400 ºC |