Process Data Sheet

EOS StainlessSteel 316L-4404 for EOS M 290 | 40µm

EOS M 290 - 40 µm - TRL 3

Process Information Metal

EOS StainlessSteel 316L-4404 has chemical composition corresponding to DIN EN 10088-3. For more information regarding the powder product, please refer to the EOS StainlessSteel 316L-4404 Material Data Sheet.

The following data was generated using the system and process described below. All EOS StainlessSteel 316L parameter sets, including 40/80 µm, are compatible with EOS StainlessSteel 316L-4404 powder.

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | 316L_040_FlexM291 |

| Software Requirements |

EOSPRINT 2.7 or newer EOSYSTEM 2.11 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 63 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | 3.7 mm³/s |

| Typical Dimensional Change after HT [%] | + 0.02 % |

Chemical and Physical Properties of Parts

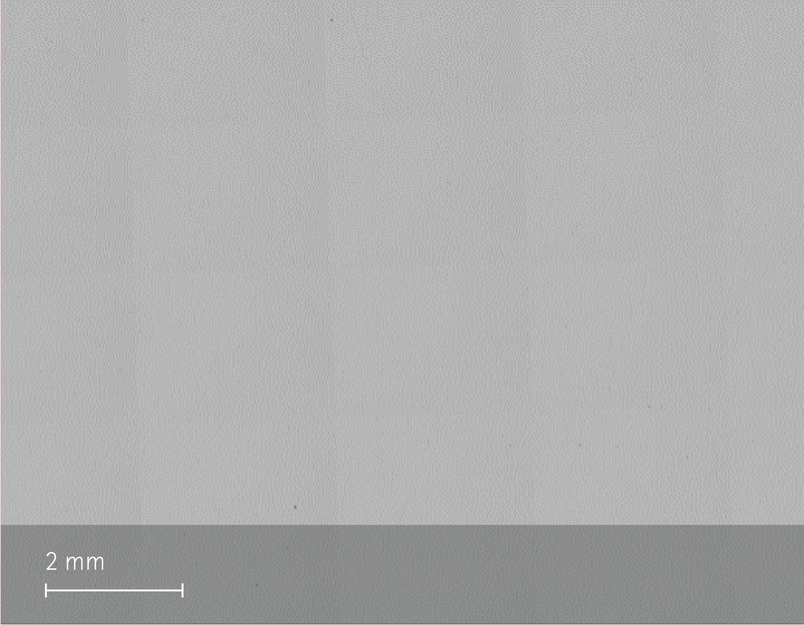

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | <0.05 % | - |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 40 µm | ≥7.97 g/cm³ | - |

Mechanical Properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 | 40 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 490 | 600 | 55 | - | - | - |

| Horizontal | 560 | 690 | 40 | - | - | - |

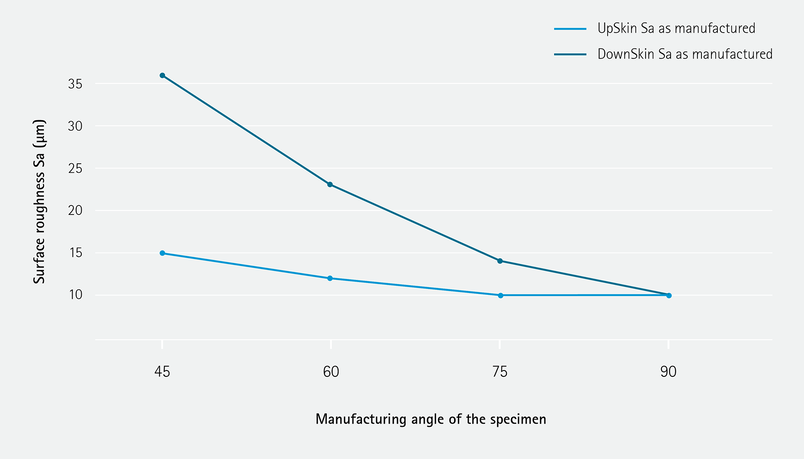

Surface Roughness