Process Data Sheet

EOS StainlessSteel 316L-4441 for EOS M 290 | 20 µm

EOS M 290 - 20 µm - TRL 9

Process Information Metal

This process product is optimized for robustly building parts with EOS M290 system using EOS StainlessSteel 316L-4441. The mechanical properties have been validated to TRL9 level.

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | 316L_Surface |

| Software Requirements |

EOSPRINT 2.7 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | Standard |

| Inert gas | Argon |

| Sieve | 63 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 20 µm |

| Volume Rate | 2.0 mm³/s |

| Wall Thickness | 0.3 - 0-4 mm |

| Typical Dimensional Change after HT [%] | +0.02 % |

Chemical and Physical Properties of Parts

Chemical composition of built parts is compliant to EOS StainlessSteel 316L powder chemical composition.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 20 µm | 0.018 % | 45 |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 20 µm | ≥7.97 g/cm³ | 45 |

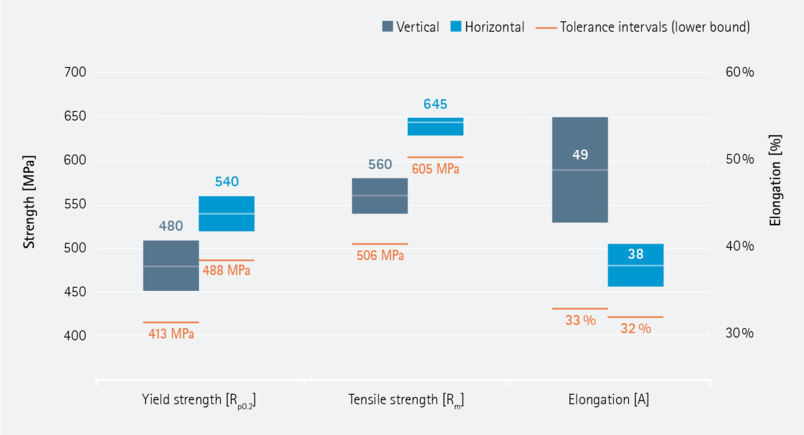

Mechanical Properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | 20 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 480 | 560 | 49 | - | - | 363 |

| Horizontal | 540 | 645 | 38 | - | - | 246 |

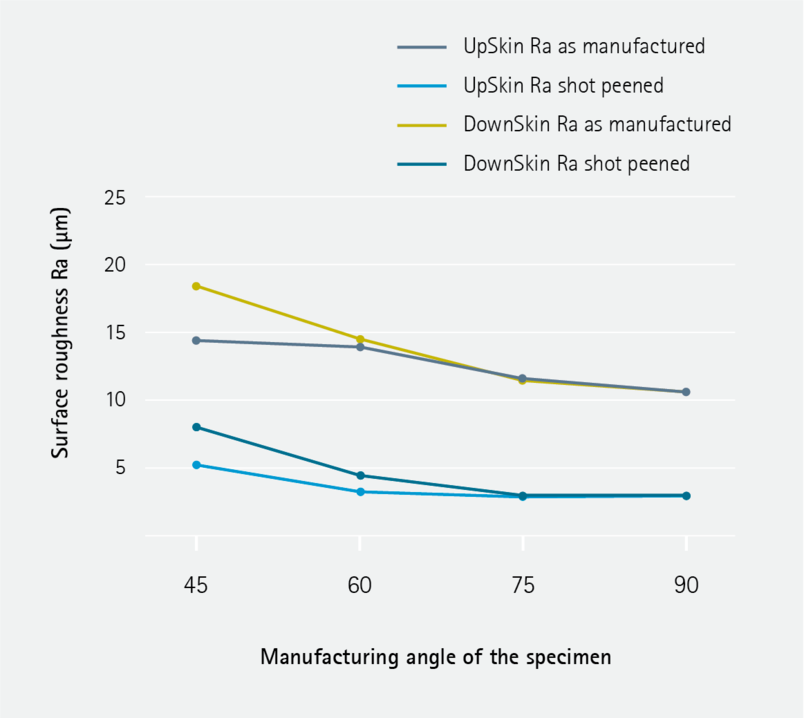

Surface Roughness

Coefficient of Thermal Expansion

| As Manufactured | Temperature |

|---|---|

| 15.72*10-6/K | 25 – 100 ºC |

| 16.75*10-6/K | 25 – 200 ºC |

| 17.27*10-6/K | 25 – 300 ºC |

| 17.7*10-6/K | 25 – 400 ºC |