Process Data Sheet

EOS StainlessSteel 316L-4441 for EOS M 290 | 40 µm

EOS M 290 - 40 µm - TRL 7

Process Information Metal

This process product is optimized for building high quality parts with EOS M 290 system reliably using EOS StainlessSteel 316L-4441. Mechanical properties have been validated to TRL7 level.

| System Setup | EOS M 290 |

|---|---|

| EOS Material set | 316L_040_FlexM291 |

| Software Requirements |

EOSPRINT 2.7 or newer |

| Recoater Blade | HSS (High Speed Steel) |

| Nozzle | EOS Grid Nozzle |

| Inert gas | Argon |

| Sieve | 63 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40 µm |

| Volume Rate | 3.7 mm³/s |

| Wall Thickness | 0.1 mm |

| Typical Dimensional Change after HT [%] | +0.2 % |

Chemical and Physical Properties of Parts

Chemical composition of built parts is compliant to EOS StainlessSteel 316L powder chemical composition.

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | 0.015 % | 20 |

| Density EN ISO 3369 | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 40 µm | ≥7.97 g/cm³ | 20 |

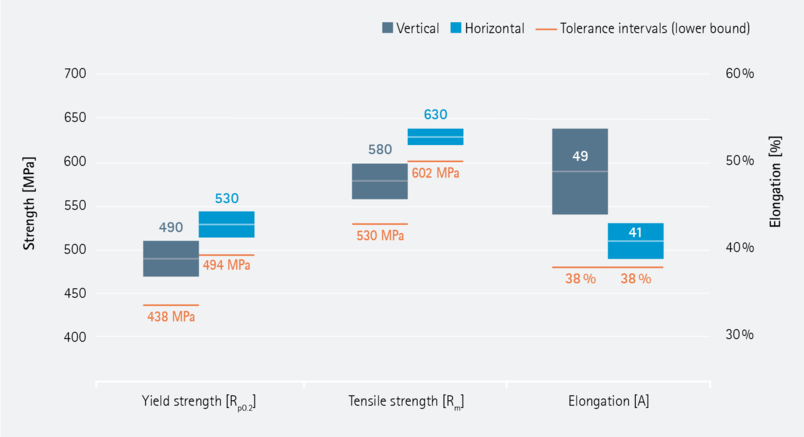

Mechanical Properties

Mechanical Properties As Manufactured

| EN ISO 6892-1 Room Temperature | 40 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 490 | 580 | 49 | - | - | 162 |

| Horizontal | 530 | 630 | 41 | - | - | 72 |

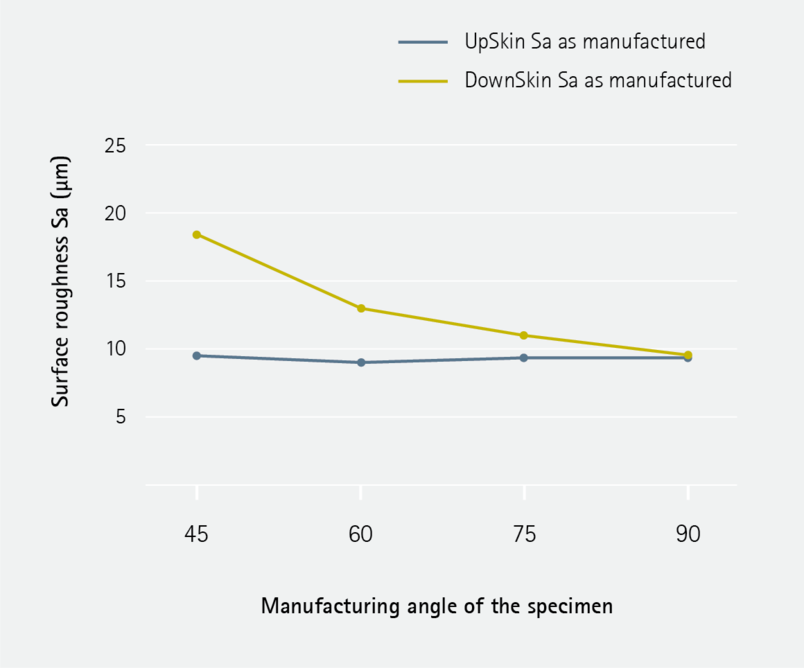

Surface Roughness