EOS StainlessSteel CX for EOS M 400-4 | 40/80 µm

EOS M 400-4 - 40/80 µm - TRL 3

Process Information Metal

This process product is optimized for flexible and fast production of CX parts with EOS M 400-4 system. The parameter set has three different layer thickness options that can all be utilized within the same build: 40µm, 80 µm and 40/80 µm Skin. For high productivity needs a 80 µm parameter set is included with a build rate more than double the long established 40 µm parameter set. Both can be used separately for different parts or combined by using 40/80 µm Skin with faster 80 µm for the core of the part and higher quality 40 µm building for the surface of the part with defined thickness. Sectionioning parts in vertical direction for different parameters is also possible.

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | CX_040_080_Core M404 |

| Required Software Plan | EOS BUILD |

| Software Requirements |

EOSPRINT 2.16 or higher |

| Recoater Blade | Ceramic |

| Nozzle | Standard |

| Inert gas | Nitrogen |

| Sieve | 75 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 40/80 µm |

| Volume Rate | 4.1 -7.8 per laser mm³/s |

| Typical Dimensional Change after HT [%] | +0.1 % |

Chemical and Physical Properties of Parts

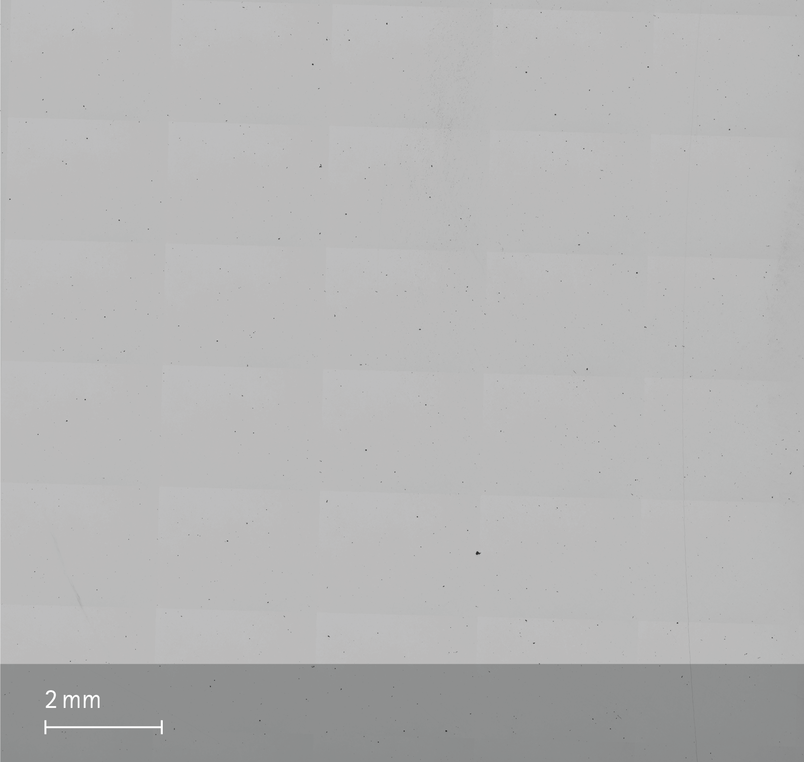

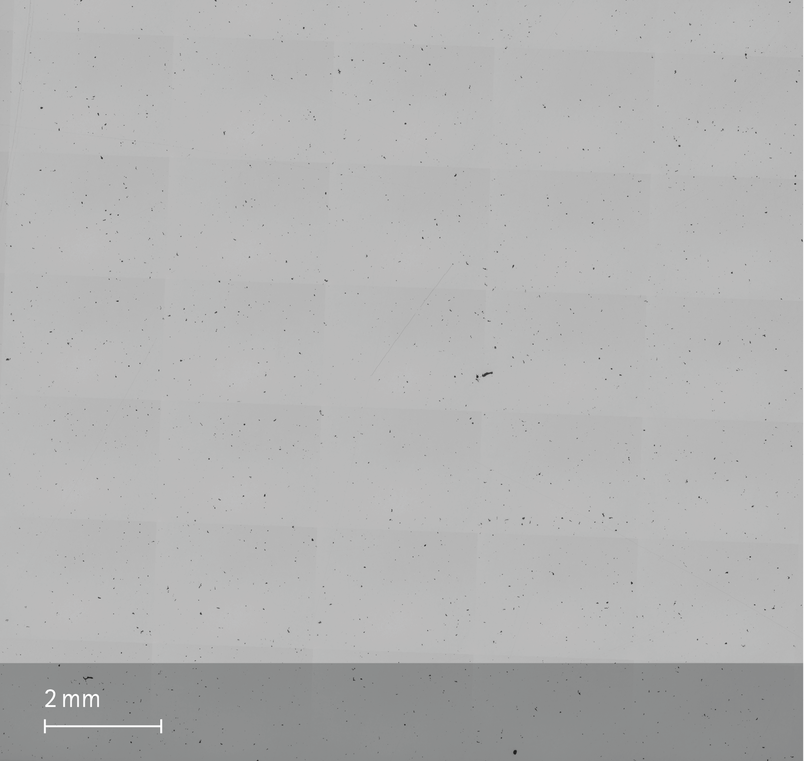

Etched micrograph of powder with 40 µm (left), 80 µm (right)

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 40 µm | <0.1 % | - |

| Density | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Density | 80 µm | <0.2 g/cm³ | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | 40 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 1650 | 1720 | 5.5 | - | - | - |

| Horizontal | 1650 | 1720 | 6.5 | - | - | - |

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | 80 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 1600 | 1690 | 4.5 | - | - | - |

| Horizontal | 1610 | 1700 | 5.5 | - | - | - |

Impact Toughness

| EN ISO 148-1, Charpy-V Heat Treated | |

|---|---|

| Typical Impact Toughness [J] | 14 |

| Layer Thickness | 40 µm |

| Heat Treated | |

|---|---|

| Typical Impact Toughness [J] | 10 |

| Layer Thickness | 80 µm |

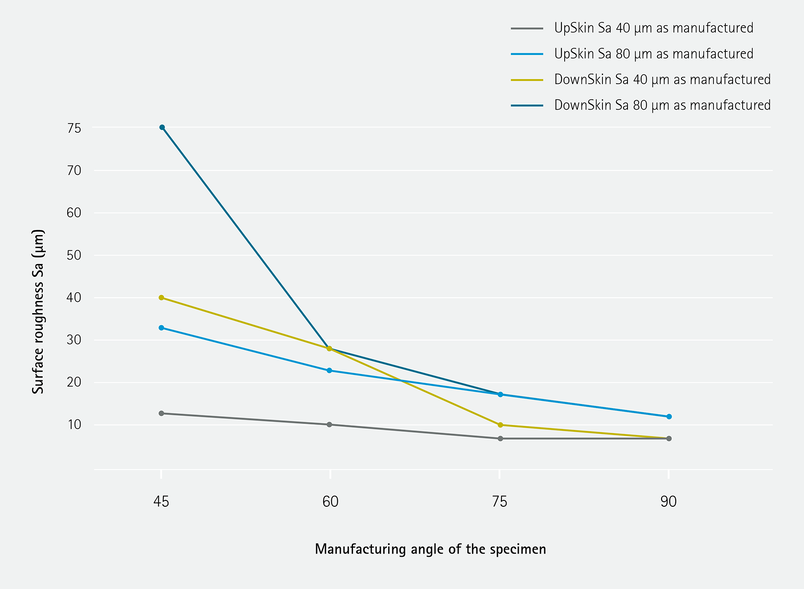

Surface Roughness