Process Data Sheet

EOS Titanium Ti64 for EOS M4 ONYX | 60 µm

EOS M4 ONYX - 60 µm

Process Information Metal

The M 4 ONYX Ti64 60 µm process combines significant productivity gains, excellent surface finish, and exceptional cleanliness, making it ideal for demanding titanium applications.

Key innovations include optimized scanning strategies and exposure techniques that dramatically reduce non-productive movements, enabling faster builds with outstanding quality.

Please note that the following data is a preview. Additional statistics and detailed insights will be published shortly.

Highlights:

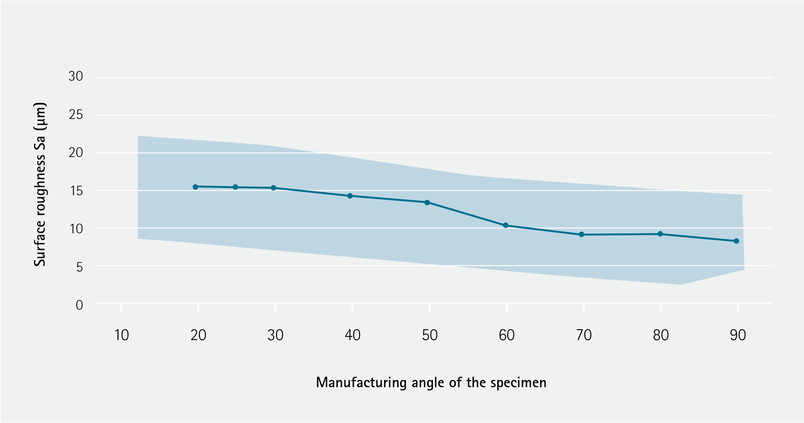

- Outstanding surface quality: Sa values < 15 µm down to 25°.

- Improved buildability: Down to 20°/25° without support.

| System Setup | EOS M4 ONYX |

|---|---|

| Required Software Plan | EOS BUILD |

| Recoater Blade | HSS (High Speed Steel) |

| Inert gas | Argon |

| Sieve | 63 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 60 µm |

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 60 µm | < 0.01 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | 60 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 1075 | 1140 | 14 | - | - | - |

| Horizontal | 1035 | 1020 | 11 | - | - | - |

2h @ 800°C in vacuum

Surface Roughness