EOS MaragingSteel MS1 for EOS M 400-4 | 80 µm

EOS M 400-4 - 80 µm - TRL 3

Process Information Metal

This process product is optimized for fast production of MS1 parts with EOS M 400-4.

| System Setup | EOS M 400-4 |

|---|---|

| EOS Material set | MS1_080_CoreM404 |

| Required Software Plan | EOS BUILD |

| Software Requirements |

EOSPRINT 2.16 or newer |

| Recoater Blade | Ceramic |

| Nozzle | EOS Aerospike Nozzle |

| Inert gas | Nitrogen |

| Sieve | 63 µm |

| Additional Information | |

|---|---|

| Layer Thickness | 80 µm |

| Volume Rate | up to 4 x 7.68 mm³/s |

Chemical and Physical Properties of Parts

Chemical composition of built parts is compliant to EOS MaragingSteel MS1 powder chemical composition.

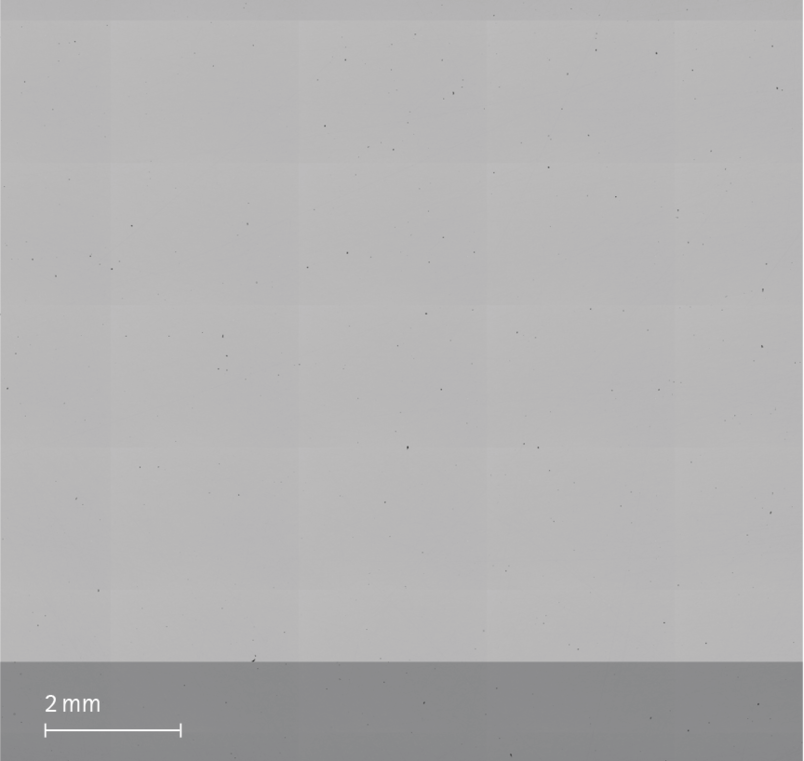

Microstructure of the Produced Parts

| Defects | Thickness | Result | Number of Samples |

|---|---|---|---|

| Average Defect Percentage | 80 µm | <0.1 % | - |

Mechanical Properties

Mechanical Properties Heat Treated

| EN ISO 6892-1 Room Temperature | 80 µm | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break A [%] | Reduction of Area Z [%] | Modulus of elasticity [GPa] | Number of Samples |

|---|---|---|---|---|---|---|

| Vertical | 1980 | 2050 | 4 | - | 190 | - |

| Horizontal | 1990 | 2055 | 4 | - | 190 | - |

Modulus of Elasticity according to ASTM E 132-04

EOS MaragingSteel can be heat treated to match various needs of different applications. The two step heat treatment can be performed under vacuum or inert gas atmosphere. First step is solution annealing to minimize amount of austenite in the martensitic matrix. The needed hardness and strength is achieved through aging treatment where hardening takes place through forming of intermetallic phases and precipitates.

Solution annealing:

2 h at 940 °C (±10 °C) measured from the part followed by rapid air cooling to room temperature (below 32 °C). Cooling rate 5-60 °C/min.

Reaching room temperature before starting aging treatment is required to achieve desired microstructure.

Aging:

For peak hardness of 54 HRC age 6 h at 490 °C (±10 °C) measured from the part followed by air cooling.

Mechanical properties presented in this document achieved through this aging procedure.

Modulus of Elasticity according to ASTM E 132-04

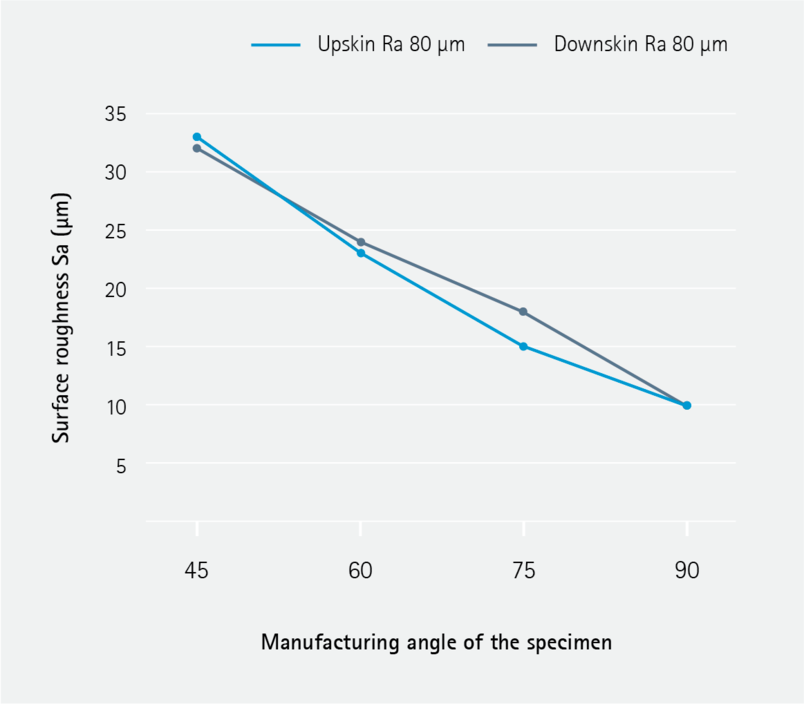

Surface Roughness

Coefficient of Thermal Expansion

| Temperature | |

|---|---|

| 10.6*10-6/K | 25 – 100 ºC |

| 10.9*10-6/K | 25 – 200 ºC |

| 11.2*10-6/K | 25 – 300 ºC |

| 11.5*10-6/K | 25 – 400 ºC |