EOS Steel 42CrMo4

Material Data Sheet

EOS Steel 42CrMo4

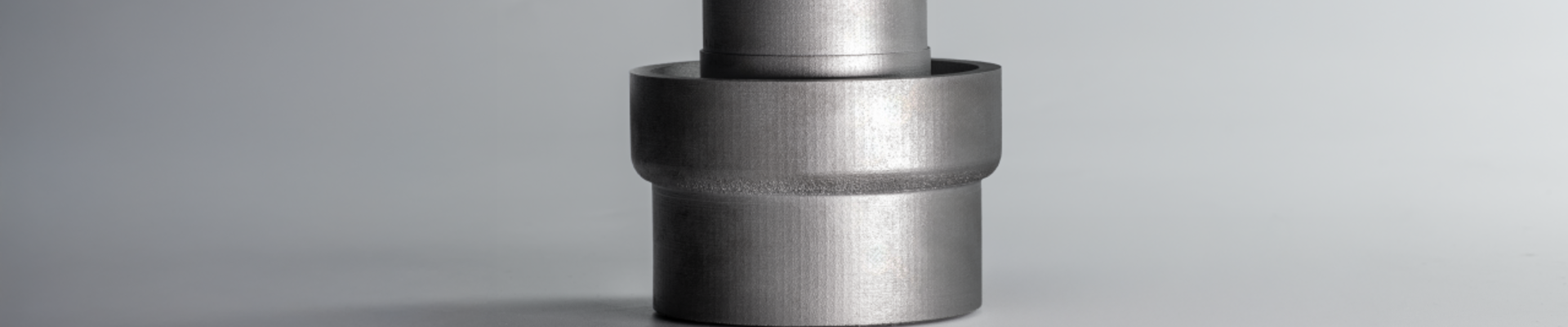

EOS Steel 42CrMo4 is a martensitic carbon hardening quench and tempering steel with high strength and toughness. EOS 42CrMo4 corresponds to EN 10083-3 (1.7225, AISI 4140). 42CrMo4 can be heat treated for use in components with different requirements.

- High strength

- High toughness

- Engineering components

- Shafts

- Gears

The EOS Quality Triangle

EOS incorporates these TRLs into the following two categories:

- Premium products (TRL 7-9): offer highly validated data, proven capability and reproducible part properties.

- Core products (TRL 3 and 5): enable early customer access to newest technology still under development and are therefore less mature with less data.

All of the data stated in this material data sheet is produced according to EOS Quality Management System and international standards

POWDER PROPERTIES

The chemical composition of EOS Steel 42CrMo4 is in compliance with EN 10083-3.

Powder Chemical Composition (wt.-%)

| Element | Min. | Max. |

|---|---|---|

| Fe | Balance | |

| Cr | 0.9 | 1.2 |

| Mn | 0.6 | 0.9 |

| C | 0.38 | 0.45 |

| Si | - | 0.4 |

| Mo | 0.15 | 0.3 |

| S | - | 0.035 |

| P | - | 0.025 |

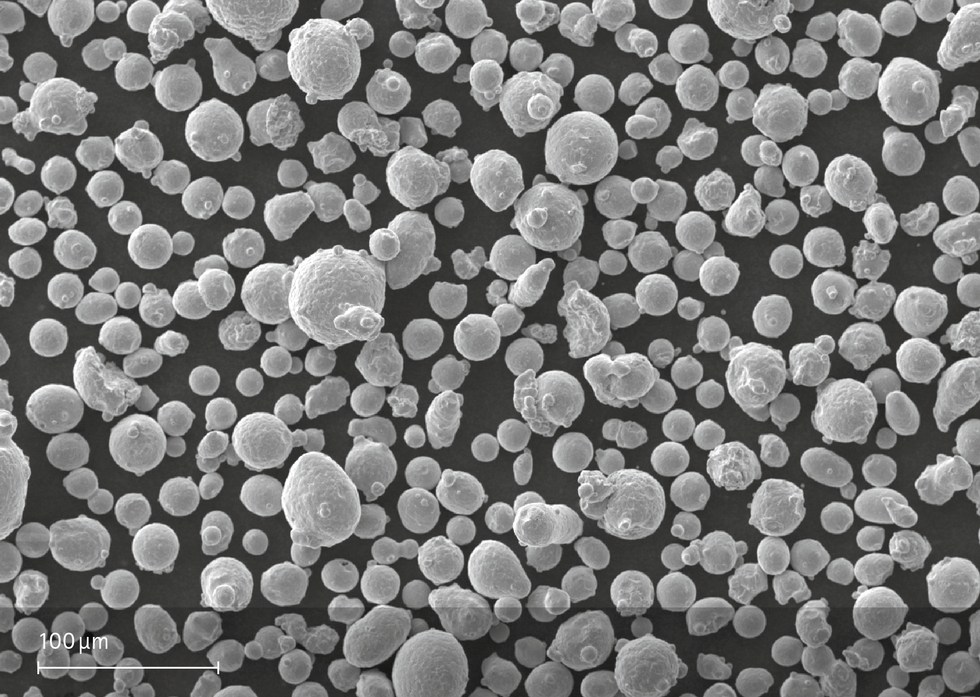

Powder Particle Size

| GENERIC PARTICLE SIZE DISTRIBUTION | 15 - 53 μm | |

|---|---|---|

SEM image of powder

HEAT TREATMENT

EOS 42CrMo4 can be heat treated to match various needs of different applications. The two step heat treatment can be performed under vacuum or inert gas atmosphere. First step is austenizing and quenching to achieve martensitic structure. Second step is tempering. Optionally 42CrMo4 can be stress relieved before quench and tempering.

Optional Stress Relieve

2 h at 600 °C followed by cooling in air

Quench

0.5-1 h at 860 °C (±20 °C) measured from the part followed by quenching in oil or water to room temperature (below 32 °C).

Tempering

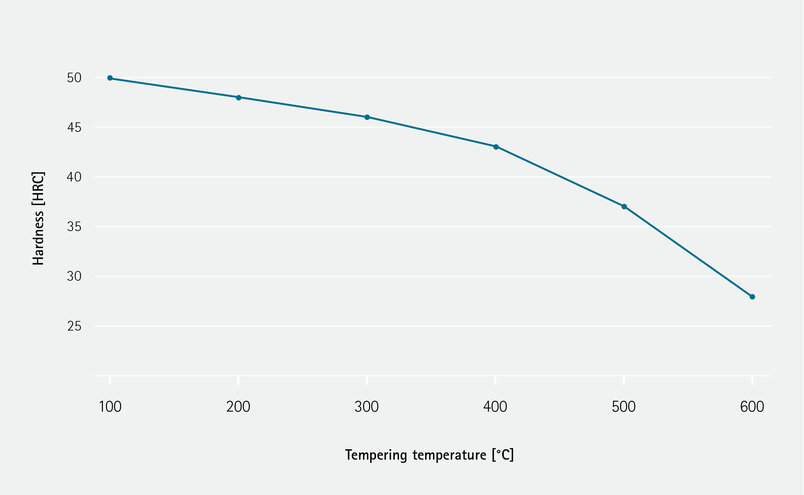

1-2 h at 550 °C (±20 °C) followed by cooling in air. This tempering gives optimum combination of strength and toughness. Tensile data in this MDS is from this heat treatment. If other hardness is required choose tempering temperature from the graph below.