POLYMER SOLUTIONS

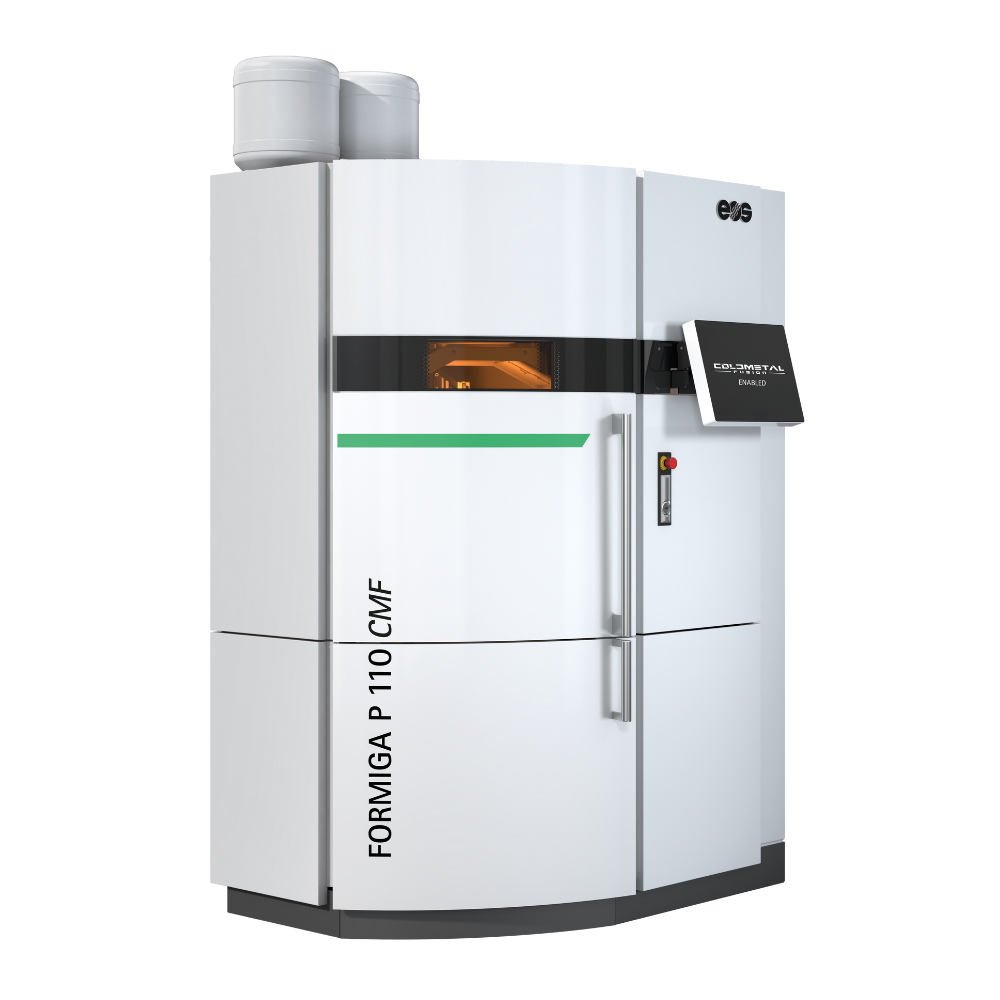

System Data Sheet: FORMIGA P 110 CMF

- Support‑Free Titanium Production: Complex geometries — including impellers, diffusers, and internal flow channels — can be manufactured without support structures, maximizing build productivity and enabling designs not achievable through casting or forging.

- Low‑Temperature CMF Process: Selective laser sintering of CMF feedstock at approx. 30–50 °C.

- Sinter‑Based Titanium Properties: After debinding and furnace sintering, components achieve powder‑metallurgical Ti‑6Al‑4V quality with excellent corrosion resistance and fatigue performance.

- Optimized for CMF Feedstocks: Hardware upgrades include titanium‑compatible material containers, pneumatic‑assisted powder feeding, enhanced grounding and cabling, and CMF‑specific process monitoring (oxygen and thermal environment control).

- CMF Feedstock by Headmade Materials: All unused powder can be 100 % reused without aging or degradation, reducing operating costs and improving process reliability.

- Low‑CAPEX Entry into Metal AM: The FORMIGA P 110 CMF leverages a mature polymer SLS platform, enabling cost‑efficient adoption of metal additive manufacturing without investment in high‑power laser or reactive‑metal systems.

FORMIGA P 110 CMF

Industrial ColdMetalFusion Machine for Titanium (Ti‑6Al‑4V) Production

The FORMIGA P 110 CMF is an industrial ColdMetalFusion (CMF) system engineered for the cost‑efficient production of titanium components. Based on the proven FORMIGA platform, the P 110 CMF enables support‑free, low‑temperature printing of Ti‑6Al‑4V green parts using CMF polymer‑metal feedstocks, followed by standard debinding and furnace sintering. The result is a reliable, accessible, and scalable titanium casting alternative designed for pumps, valves, fluid‑handling systems, and other industrial applications requiring corrosion‑resistant, lightweight, and highly complex components.

EXPOSURE MODULE

LASERS

- 1 x

30 W

FORMIGA P 110 CMF

TECHNICAL DATA

| BUILD VOLUME | 200 x 250 x 330 mm (7.9 x 9.8 x 13.0 in) |

| LASER TYPE | CO₂; 1 x 30 W |

| PRECISION OPTICS | 1 F-theta-lens(es); 1 High-speed scanner(s) |

| SCAN SPEED | up to 5.0 m/s (16.4 ft/s) |

| POWER SUPPLY | 1 x 16 A |

| POWER CONSUMPTION | max. 5.0 kW / typical 3.0 kW |

MATERIALS & PROCESSES

EOS has exceptional materials expertise and a comprehensive portfolio of highly developed materials for additive manufacturing. Our materials, systems and process parameters fit together optimally. With the right materials, you can realize the desired property profiles in the best possible way for your products