EOS Pilot Production Line - Ready for you!

December 07, 2021 | Reading time: 5 min

EOS can optimize and verify customer production throughput, part quality, and business cases for critical parts and workflows with metal and polymer pilot production lines. Our digital factory near Munich airport is ready for your ideas with state-of-the-art Additive Manufacturing and post-processing equipment.

Test and optimize your AM production line

Establishing an AM production line for a new part can be tedious and take a long time because many variables exist. I want to guide you through a step-by-step approach that includes a high degree of flexibility and customized focus. The result will be a clear production line vision with all relevant costs and a transparent way forward.

Introducing our new four-pillar AM Production Optimization service (AMPO)

Why do we offer such a complex service? EOS decided to invest in a comprehensive production line for its customers to address their main pain points such as:

- I am not sure that how to achieve my specific application-driven business case

- The risk to execution is too high

- My factory is complex, and I am not getting the most value out of it, but how do I know what to change to improve it?

- My EOS printer's downtime is too high and the maintenance too expensive.

If you ask yourself some of these questions, our offering can be the right way to go. Let me explain in detail what you can expect.

The Setup

Near Munich Airport, in Maisach, we are running two separate production factories for metal and polymer Additive Manufacturing that we make available to you. Each factory has multiple production lines using different EOS systems and periphery equipment. The first three pillars shown above are a great start to understanding if outsourcing or insourcing is beneficial. EOS offers a unique service with the fourth pillar: Customers can verify all variables directly in a real production environment!

Together with trainers and application specialists, we set up a production environment and test critical production steps in an operational factory used for internal EOS sinter parts. Essential production steps are no longer only determined after making an investment decision and after installation at a customer. This minimizes the risk and enables a smooth transition to production.

Moreover, your staff can be trained in our 600m² facilities to get a firsthand understanding of the operation, cleaning intervals, process optimization, and possible outlooks to future automation concepts with the latest state-of-the-art equipment!

Currently, we have the following production equipment and software integration installed that is now ready to use. Also, if this does not cover your specific requirement, we can easily add other EOS machines or even 3rd party equipment if needed.

Equipment and Software

AMPO Equipment PDF - An overview of the hardware and software that is ready for you

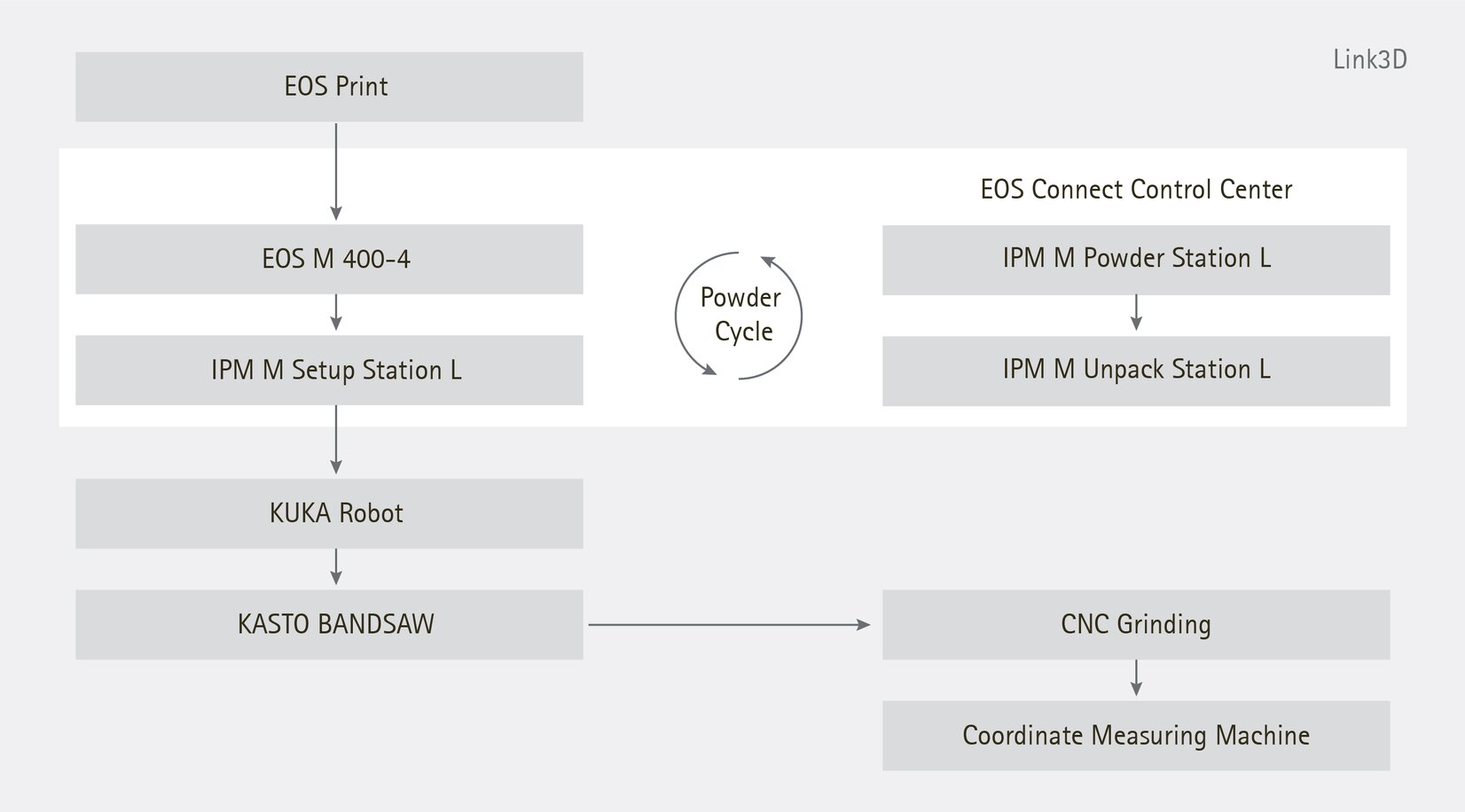

A possible combination of an EOS M 400-4 line with different post-processing equipment to simulate the product flow from the beginning with the preparation in EOSPRINT to the finished part. The last step in this layout is measuring the part on a Coordinate Measuring machine by Zeiss to verify the quality requirements on this production line. For a more thorough cleaning, the integration of a Solukon fine cleaning machine is possible after the IPM M Setup Station L.

Combination with the EOS P 500 line

For the polymer line, a possible setup includes an EOS P 500 and different post-processing equipment. We can always customize scenarios to the need of your specific business case. The software suggested here can be changed to a more suited one for your company. Please get in contact with us anytime if you have a special request.

Deep dive into our modules

1. Planning Table and rough layout

The first station to evaluate the production plant is our planning table. With theplanning table, we aim to test various machine and equipment setups. After identifying the optimal configuration, we can load the configuration in Siemens Tecnomatix and calculate the first estimations for productivity to determine the best solution.

The recognition happens instantly with a camera above the setup and recognizes machines, powder management or post-processing equipment on the planning table. A software then places the models in a virtual simulation to give a first glance on:

- Machine utilization

- Total part throughput

- Failure rate

- And many more details

2. Simulation in Tecnomatix

Now we take your initial layout to the next level and simulate it. A successful business case for serial production needs an in-depth analysis of all the production parameters that impact the output and the costs. These production parameters are often related to each other in a non-linear way, and therefore, it isn't easy to optimize them using a formula. On the other hand, simulation software takes all production-related complexities into account and can solve the optimization problem easier than a spreadsheet tool. Here we use Tecnomatix Plant Simulation from Siemens. The learning curve for such a simulation tool can be high, and hence it makes sense for the customer to contact us. Not only do we have the expertise to simulate production, but we also have the best know-how of our AM machines and auxiliary equipment. This helps us model a customized simulation efficiently and is also time-saving for the customer.

We are using the simulation software not only for the AM process but also for the post-processing steps. It is essential for a successful AM business to analyze the post-processing throughput and costs, which can sometimes make or break a business case. Simulation makes it easier to scrutinize the complex process chain when you need to consider numerous parameters.

3. Cost calculation tailored to you needs

The financials behind the simulation are accessible for you. With our financial calculator, we can take a deep dive into the world of unforeseen costs beyond the machine running costs. Our focus is on the complete production workflow, from file preparation with specific software tools to the finished product with its post-processing steps. Again, we can customize these steps to your need.

We can also include different worker costs, consider holidays, unplanned downtime, powder price development over a certain period, or, as shown in the following picture, what the biggest levers for cost reduction are. We can then use this result to either optimize the production workflow or the part geometry itself. Sometimes, a different viewpoint on a part can open new possibilities to print those parts economically.

Test-run verify simulation and calculation results

In Maisach, we can offer you access to a fully functioning production line with the state-of-the-art polymer and metal equipment mentioned above. Here, we verify together with a trained team the simulation and cost calculation side and can look at critical factors or process steps. This allows us to eliminate the last doubts to start producing the parts with additive manufacture.

How we set-up production for YOU MAWO

The production start of the YOU MAWO eyewear company was tested and pushed to serial production at EOS in Maisach. Together with our experts, we set up a complete production line for polymer and optimized the whole workflow to get a profitable result. Especially regarding surface roughness, we could meet the high demand of YouMawo's requirements. YouMawo is now producing eyewear frames in large quantities.

We have proven with this pilot line that the eyewear production process meets quality and cost per part.

Sebastian Zenetti | CEO YOU MAWO