3D Printing for Aviation

Enabling Lightweight, High-Performance Aircraft Components Through Advanced AM

Industrial 3D printing is reshaping how aircraft components are designed and manufactured. Whether for engines, turbines, or lightweight cabin structures, additive manufacturing enables highly complex geometries, improved aerodynamic performance, and significant weight reduction — all while lowering production costs and shortening lead times.

Lightweight design, functional integration, and material efficiency are crucial for improving fuel consumption and meeting increasingly strict sustainability and regulatory requirements. As a result, leading aerospace OEMs and suppliers are integrating additive manufacturing into their long-term production strategies to remain competitive and accelerate innovation.

EOS empowers this transformation with end-to-end additive manufacturing solutions: industrial-grade 3D printing systems, validated materials, proven process qualification, and deep aerospace expertise. This close collaboration has resulted in numerous certified applications and is driving continuous innovation across the global aviation sector.

Expanding the Potential of AM: From Aircraft to Advanced Drone & UAV Systems

The same AM advantages - lightweight structures, optimized performance, and rapid design iteration - are becoming critical in next-generation drone and UAV applications. Additive manufacturing enables faster development cycles, improved payload efficiency, and highly customized aerodynamic components, making it a strategic technology for the future of unmanned flight. See more details on the Drones & UAVs page.

Advantages of 3D Printing for Aviation

EOS Projects From Practice

Manufacture Engine Parts for Aviation

Industrial 3D printing enables highly efficient engine and turbine components by combining complex geometries, optimized aerodynamics, and lightweight structures - often up to 60% lighter than conventionally manufactured parts. Even demanding superalloys can be processed more economically thanks to reduced material waste, resulting in lower fuel burn and a smaller environmental footprint. Monolithic, single-piece components offer enhanced strength and durability. With fewer joints and seams, they deliver higher reliability and contribute to improved engine safety.

Sogeti High Tech

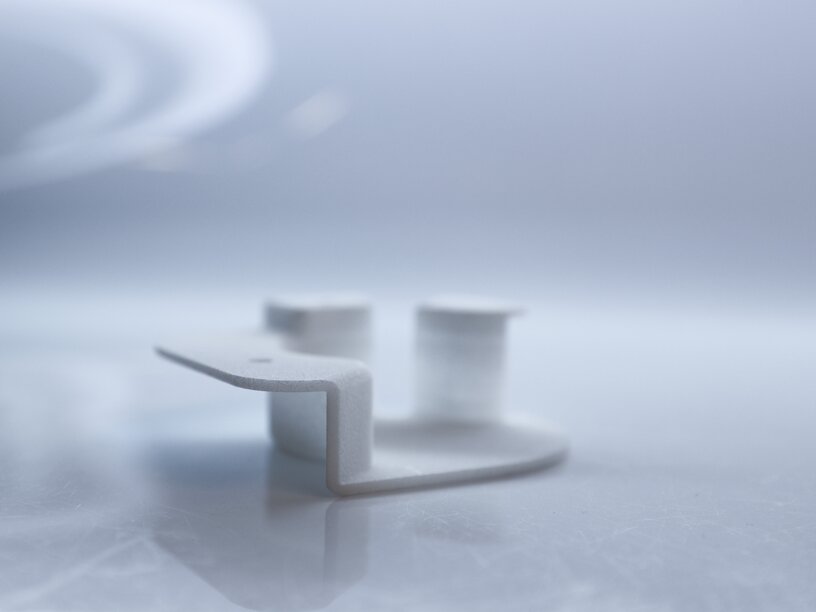

Sogeti High Tech and EOS developed an additively manufactured, fully integrated cable-routing mount for the Airbus A350 XWB in just two weeks, reducing 30 parts to one, cutting production time by over 90%, and lowering the component’s weight by 135 grams.

- -29 Single Parts Functional integration

- -90% Reduction of production time

- -135 Grams Reduction of weight

MTU Aero Engines

MTU Aero Engines, Germany’s leading engine manufacturer, has optimized its EOS machines to manufacture safe and cost-efficient parts in series. Using additive manufacturing, MTU builds borescope bosses for the geared turbofans of the new generation of PurePower® PW1100G-JM engines by Airbus A320neo. The low-pressure turbine in the A320neo turbofan is the first turbine ever to be equipped with additively manufactured borescope bosses by default. The cost benefits of EOS technology were one of the decisive factors for both production and development.

Quality Assurance for Aviation

Aviation requires maximum safety, meaning every flight-critical part must be monitored with zero defects allowed. EOS and MTU Aero Engines jointly developed EOSTATE Exposure OT, an optical tomography solution for in-process monitoring. It delivers detailed layer-by-layer quality insights, enhances reproducibility, and enables cost-efficient quality assurance for serial AM production.

Airbus

3D printing technology by EOS helps Airbus to build a more cost- and resource-efficient aircraft. An AM locking shaft for aircraft doors achieved remarkable results:

-

45% weight reduction with identical robustness

-

25% lower production costs through reduced material & assembly time

-

Reduction from 10 parts to 1 integrated component

-

Over 4 kg weight reduction across all 16 door shafts per A350 aircraft

Manufacture Assemblies and Structural Parts

AM unlocks new possibilities for structural aerospace components. By consolidating multiple parts into a single optimized component, it reduces assembly steps, complexity, and cost drivers.

On-demand production transforms spare-parts logistics and eliminates the need for large inventories. Significantly lighter components also improve aircraft efficiency and reduce CO₂ emissions.

Transforming the Future of MRO

The blog explains how industrial 3D printing is transforming aircraft MRO (Maintenance, Repair and Overhaul) by enabling faster, cheaper and more flexible on-demand production of certified spare parts - especially cabin interior components - while reducing inventory, shortening lead times, and improving sustainability through lighter, more efficient designs.

3D Printing for Aircraft Interiors

Polymer-based AM is becoming increasingly important for aircraft cabin interiors, where high customization, tool-free production, and strict flammability requirements are essential. Industrial polymer 3D printing processes certified materials, allows complex geometries, and ensures repeatable builds with minimal post-processing.

It also enables digital spare-part strategies with virtual inventories and on-demand production - making polymer AM an efficient, compliant, and highly adaptable solution for cabin components.

Etihad Engineering

Etihad Engineering is the largest MRO service provider in the Middle East, offering design, composite repairs, cabin refitting, and part services at its modern facilities in Abu Dhabi.

"Together with EOS, Etihad opened the first EASA-approved 3D printing facility in the Middle East for designing and manufacturing aircraft parts."

Using the EOS P 396 and materials such as PA 2241 FR, Etihad can quickly produce certified polymer cabin parts - both for scheduled C-checks and for fast replacements during regular line maintenance.