3D Printing in the Manufacturing Sector

Applications and Practical Examples

Best Practices for 3D Printing in Manufacturing & Production Environments

Cost pressure, regulatory requirements, increasing demands from customers, and much more. Companies in production and industry face a constantly expanding collection of challenges. At the same time, issues such as energy and resource efficiency are becoming increasingly important.

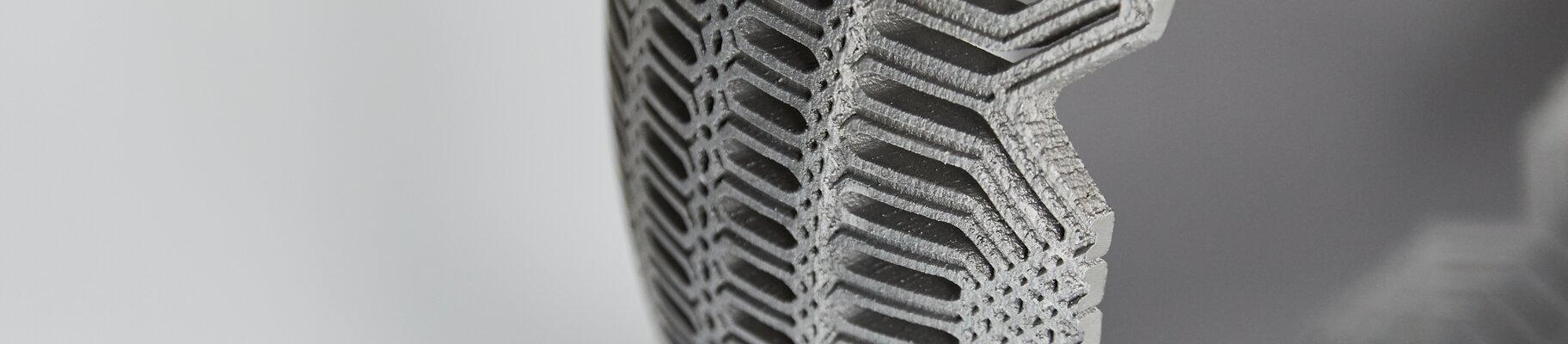

Additive manufacturing offers a broad spectrum of potential cost-efficient and sustainable advantages to companies in production and industry.

Industrial 3D printing opens new opportunities and provides solutions in many different ways, from part production to optimizing return on investment. At EOS, we offer custom solutions from a single source for technology and everything else you need for a safe and rapid transition.