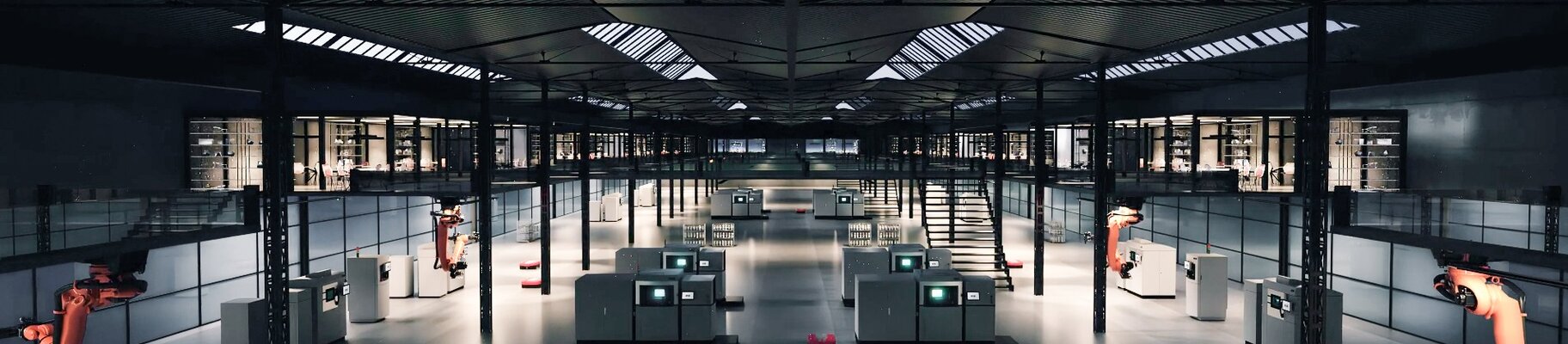

Introducing the Machine State App - your go-to tool for monitoring and controlling your machines. With a comprehensive dashboard, the app provides real-time insights on the status of your machines — reporting on all system messages — and provides graphs of the sensor data for quick error analysis.

In addition to monitoring, the Machine State App offers remote control capabilities, allowing you to stop or pause a build job from anywhere using your mobile device. The app also provides information on the current material in use and print progress, giving you complete transparency into your equipment's performance.

The Machine State App is an innovative cloud-based solution that provides access to all of your equipment information in one place, from any device. It's designed to increase your equipment's efficiency and productivity while reducing downtime, helping you to maximize your profits.

If you're looking for a reliable tool to optimize your equipment utilization, the Machine State App is the perfect solution.