Metal Manufacturing at its Best:

DMLS 3D Printing

Metal 3D Printing - The DMLS Technology

How Does it Work in Detail?

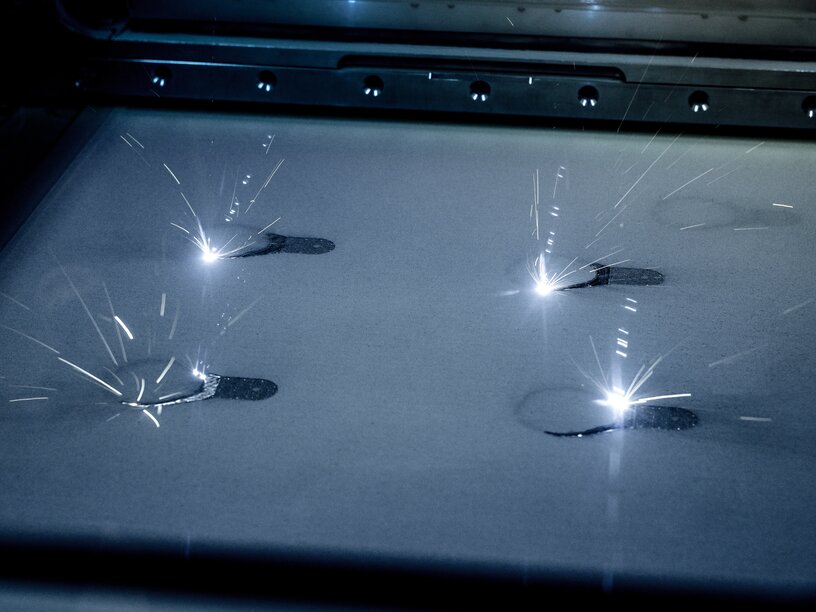

With DMLS it is possible to create metal 3D printed parts directly from a CAD model. The main requirement to create such a part is a metal powder in a metal 3D printer, where an ultra-fine layer of the metal powder is spread across the building platform.

Then, a powerful laser in the 3D printer melts the powder exactly at the points defined by the CAD model. Layer by layer, the process repeats until the part is completed.

What is Metal Additive Manufacturing?

DMLS technology, follows the principle of - "Direkt Metall Laser Schmelzen" (DMLS, Englisch translation Direct Metal Laser Melting). It is a Laser Powder Bed Fusion, or short LPBF technology, and stands for one of the world's most advanced and reliable technologies in metal additive manufacturing.

This industrial grade 3D printing technology is used for serial manufacturing of 3D printed metal parts for a wide range of industries. The main applications are aerospace, automotive, medical, tool and turbomachinery. EOS is the leading global provider for industrial metal 3D printers, materials, and services and has employed DMLS technology for more than three decades.