EOS Demo-Case Metal

Industrial 3D printing offers a wide range of technologies and processes. We support you in selecting the right material and the corresponding technical solution for your needs.

Our extensive portfolio offers a wide range of high-tech materials specifically designed for industrial 3D metal printing with our DMLS technology.

With over 20 alloys and more than 70 validated processes for all DMLS systems, additive manufacturing is possible in a wide range of different applications.

Bionic CPU Cooler

Manufactured with the EOS M 290 using EOS Aluminium AlSi10Mg.

Prove how new design freedom paves the way for radical innovations

- Usage of full flexibility of AM to increase surface areas

- Form can be adapted to any shape cavities

- Pins can be easily customized to individual chip thermal footprint

Project partner: AM METALS

Spring

Manufactured with the EOS M 290 using EOS Titanium Ti64, 60µm.

- Support-free leaf

- Surface design, single vector exposure

- 105 leaf per job

- Build time 46h28min or 9 mins per leaf

Impeller

Manufactured with the EOS M 290 using EOS StainlessSteel 316L.

Support-free DMLS® Technology allows most conventional designs to be printed while maintaining mechanical properties.

- Design optimization for weight reduction

- 3D printed and post-processed with Abrasive Flow Machining

- Small lot sizes manufactured cost-efficiently

- 300+ printed per year

- approx. 1590 EUR per impeller - 25% lower than AM with supports

- 10% material savings due to support-free printing

Project partner: AM METALS

Footrest

Manufactured with the EOS M 290 using EOS Titanium Ti64.

Foodrest printed with 60 µm process and Smart Fusion

- 50 % fewer supports

- 36 % reduction in build time per part

- 26 % reduction in cost-per-print

- Significant reduciton in post-processing

- Higher machine uptime

Project partner: Pankl Racing Systems; KTM

Bracelet

Manufactured with the EOS M 290 using EOS Stainless Steel 316L.

- No assembly necessary, printed as one part

- Locking mechanism realized with the 3D printing

- Use of pulsed laser feature for smoother surface properties

Inductor

Manufactured with the EOS M 290 1kW using EOS Copper Cu.

- Fast production of complex inductors without solder joints compared to conventional production

- Very high electrical conductivity

- Can be manufactured with all 1KW EOS Printer

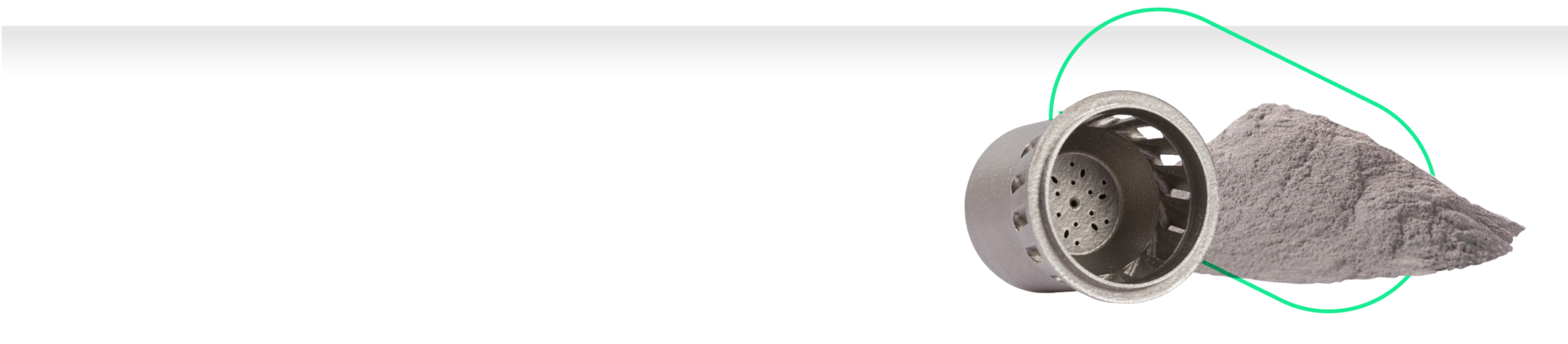

DMLS Technology Demonstration Part

Manufactured with the EOS M 290 using EOS Stainless Steel 316L.

- 36 pieces on on full building platform

- Layer thickness: 40 µm

- Building time: 76 h

- Designed by: Vincenzo Abbatiello, EOS

Conceptual CPU Cooler

Manufactured with the EOS M 300-4 using EOS Al2139 AM.

- Can be easily customized to individual chip thermal foodprint

- Can be adapted to any shape cavities

- Less weight and volume

- Support-free DMLS® Technology

Stacked PLIF Cages

Manufactured with the EOS M 290 using EOS Titanium 64 Grade 23, 40µm.

- Support-free stacked PLIP cages

- High fatigue properties without HIP

- 595 MPa fatigue strength for 10 Million cycles

- Voronoi and Gyroid lattice integrated

- 540 PLIF cages per job

- Build time 84 hours or 9,3 mins per cage

Project partner: ADDITIVE Biomechanics

Bracked

Manufactured with the EOS M 290 using EOS AlSi10Mg.

- Topology optimized bracket (aerospace)