EOS Demo-Case Polymer

Industrial 3D printing offers a wide range of technologies and processes. Selecting the most appropriate one for your needs can be tricky.

Additive manufacturing produces 3D objects by depositing material layer by layer. The process of selectively melting the powder material is particularly delicate. EOS is one of the pioneers in industrial 3D printing and has perfected the powder bed method over the past 30 years.

Customized Eyewear

Manufactured with the FORMIGA P 110 Velocis using PA 2200.

Customized series production of tailored eyewear using an app-based scan for individual face topography

- Production is 3x more sustainable as conventional manufacturing and causes 80% less waste

- CO2 footprint of eyewear is 58% lower

- Shorter supply chains, no overproduction

- White raw material ideal for dyeing

- Frames are stronger and lighter than acetate

- Custom built for custom fit

Graduated Lattice

Manufactured with the EOS P 396 using TPU 1301.

- Tune each voxel (volume pixel) for superior characteristics and true customization using 3D printing

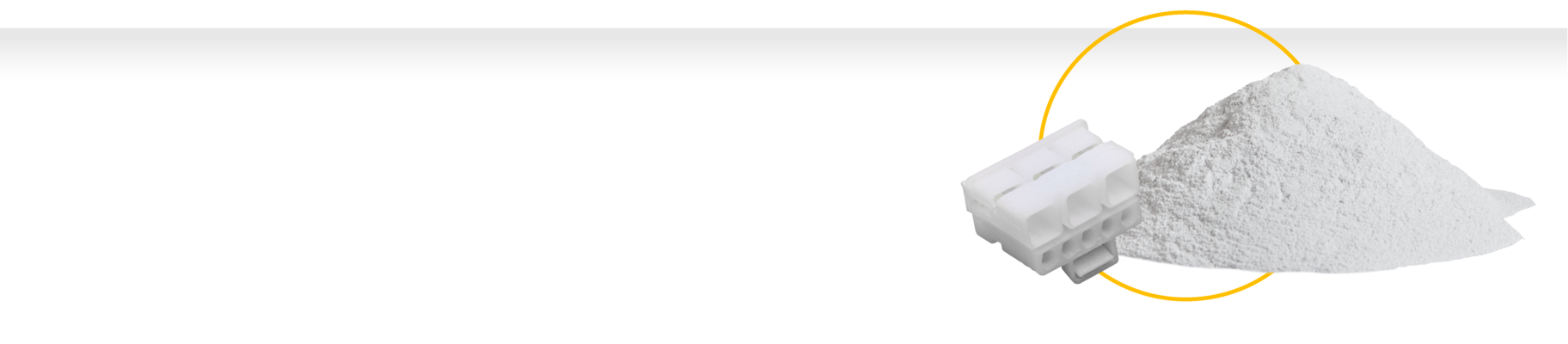

Connector Fine Detail Resolution (FDR)

Manufactured with the FORMIGA P 110 FDR using PA 1101.

- Complex and stable connector with labeling and superfine surface

Unique CO laser and new laser scanner set up producing the most delicate, yet durable parts in the market

- Extremely fine details

- Bio based PA 11 material

Book Fine Detail Resolution (FDR)

Manufactured with the FORMIGA P 110 FDR using PA 1101.

Unique CO laser and new laser scanner set up producing the most delicate, yet durable parts in the market

- Extremely fine details

- Bio based PA 11 material

Feature Box Fine Detail Resolution (FDR)

Manufactured with the FORMIGA P 110 FDR using PA 1101.

Unique CO laser and new laser scanner set up producing the most delicate, yet durable parts in the market

- Extremely fine details

- Bio based PA 11 material

Lattice Cube Fine Detail Resolution (FDR)

Manufactured with the FORMIGA P 110 FDR using PA 1101.

Unique CO laser and new laser scanner set up producing the most delicate, yet durable parts in the market

- Extremely fine details

- Bio based PA 11 material

Texture Cover

Manufactured with the EOS P 770 using PA 2200.

- Post-processing: PSS* (Compression blasting), DDC* (Coloring), PSS* (Compression blasting)

Hummingbird

Manufactured with the FORMIGA P 110 Velocis using PA 1101.

- Responsible manufacturing contributes to less material consumption, less over-production and less waste