Standing on History with Additive: EOS Team Member Receives 3D Printed Bone-Growth Geometry in Double Hip Replacement

3D printed titanium implants simplify hip replacement surgery and improve patient outcomes. Advanced technology has helped make hip replacement an important option for younger patients—like Everlee.

- 3D printed surface geometry encourages fusion with bone

- Price of 3D printed implants has come down, so some hospitals now use it as standard

- Implant technology has helped make hip replacement easier and more accessible

Few hip replacement recipients know as much about their implants as Everlee DeWall, Sales Manager at EOS’ Additive Manufacturing Customized Machines (AMCM) group. More than a decade ago while working for EOS, Everlee witnessed the creation of the same type of implant that later enabled him to walk with little to no pain after his dual hip surgeries in 2025.

In fact, Everlee even knew a bit more than his surgeon. He had been told by the surgeon he would not be receiving 3D printed implants, as those were used for special cases involving reconstruction. This was a disappointment. But then, when he looked at his chart and recognized the brand label of his implants, he knew that in fact he had received implants that had been made with EOS technology.

Hip Replacement: Now an Option for Younger Patients

Everlee suffered from hip dysplasia, a condition in which the hip socket is shallow and therefore only loosely holds the ball of the hip. Over time, the condition leads to increasing pain. And for Everlee, the combination of this condition plus degenerative osteoarthritis had led to the loss of cartilage in both hips. Initial attempts to relieve the pain including extensive physical therapy, arthroscopy and joint injections had reached the limits of their effectiveness. A specialist in hip dysplasia recommended surgery.

“The doctor said, ‘We can go in and do arthroscopy again. We can do injections forever; you can do medicine. But you are to the point where you are just buying time, so I would recommend you to a surgeon for replacement,” Everlee says.

At age 55, he thought he might have been too young for hip replacement. He expressed this concern. But the application of hip surgery has changed. Everlee’s age put him in good company, because thanks in part to easier surgeries and improved outcomes resulting from implant advances, the fastest-growing group of hip implant beneficiaries is not retirees anymore, but people age 55 to 64.

Everlee recalls, “I asked them, ‘Can I get 3D printed hip cups?’” A career in additive manufacturing (AM) has made him a witness to the way hip implants, particularly the acetabular cup component of the implant, have changed thanks to 3D printing.

The surgeon said no. 3D printed implants were customized only for reconstruction, not for a more routine surgery like this one.

But then, after the first of the two surgeries he received, Everlee says, “I was looking at my surgical notes online, and I thought, ‘That’s weird: I recognize that brand name.’”

3D Printed Implants Match the Geometry of Bone

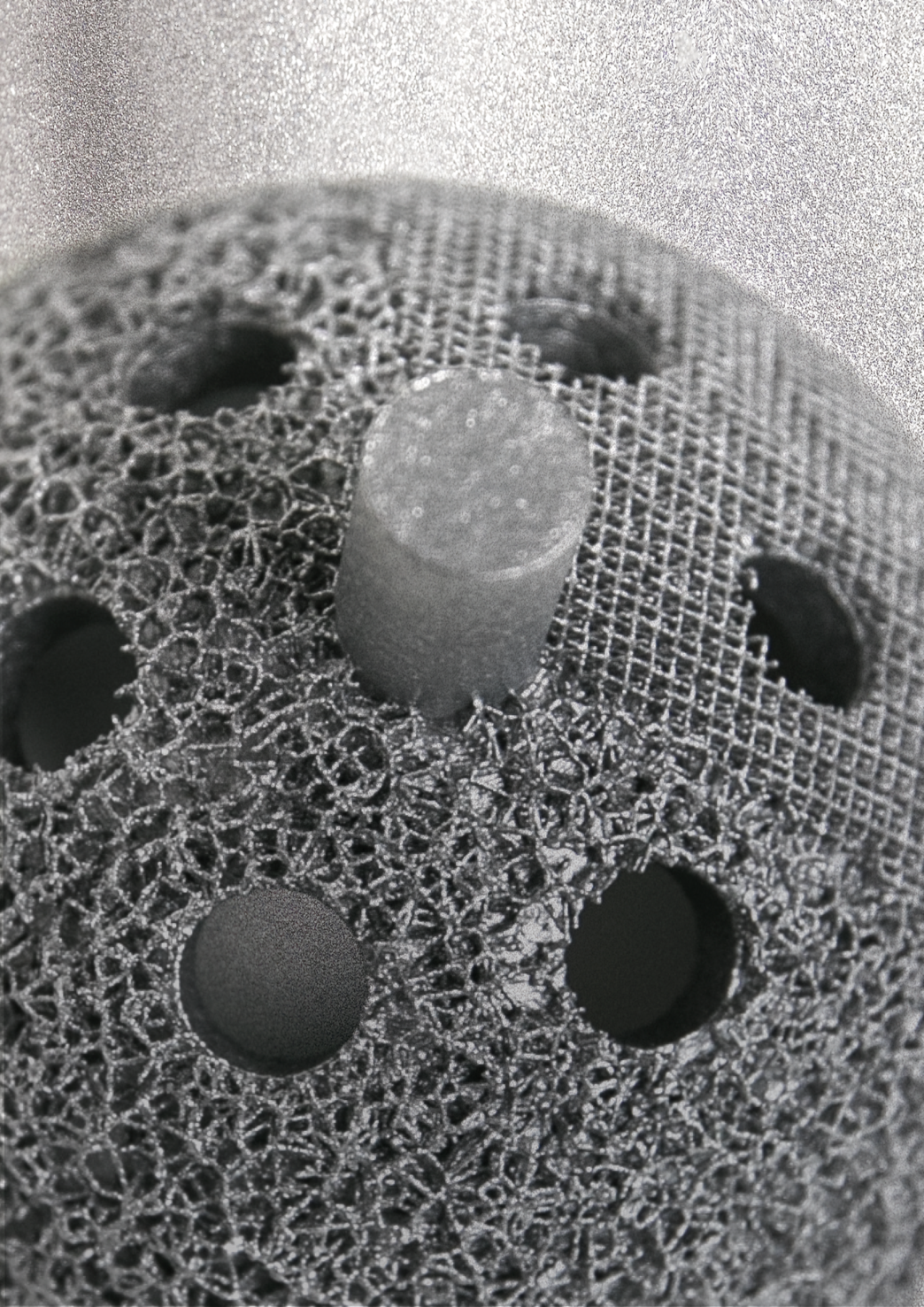

To print acetabular cups, metal 3D printing via direct metal laser solidification (DMLS) is used to produce the Ti6AI4V component, purposedly made with 70% porosity and average pore size of 475 microns, geometry that in both respects mimic the human bone. This similarity encourages bone to grow into it, creating a bond as strong as natural bone about four weeks after implanting (according to research findings). Acetabular cups are now well-established and widely used, while many surgeons may not even realize how their implants are made.

Implant selection is typically up to the surgeon’s discretion, based on what type of cup is best for a particular patient. However, now that AM has reached a higher level of production maturity and efficiency, the price difference between 3D printed acetabular cups and more conventional cups made via porous plasma spray has come down. Surgeons are now more apt to choose this better-bonding implant, and some hospitals simplify inventory by stocking only the 3D printed ones.

His surgeon knew only how well the implants work. When Everlee told him the implants were 3D printed, the surgeon went on to describe how the geometric form had changed the surgery. “For younger patients [like Everlee], now we just grind out the socket and beat the implants in,” the surgeon said, according to Everlee. “If a young patient has good bone density, no screws are needed.” The patient’s bone growth fuses with the implant. “In six weeks, you can’t pull the implants out,” the surgeon said.

EOS Technology Used from the Start

Everlee says he learned a great deal about the use of DMLS for medical implant geometry while working with the former founder and CEO Dr. Siavash Mahdavi of Within Lab’s and major medical manufacturers in the beginning of his career with EOS. Dr. Mahdavi’s Within Medical software (later acquired by Autodesk) was groundbreaking in enabling the use of EOS metal systems in the production of Titanium implants, especially acetabular cups.

Today, these medical manufacturers mass-produce implants that have fully realized this idea on the latest EOS M 290 machines in their AM production facilities both in the U.S. and abroad. By tracking the serial number of the implant, Everlee was able to confirm his original theory -- the implant he received was made with an EOS system.

Everlee Has Both Seen and Experienced How Far Hip Replacement Has Advanced

The total surgery time for each of Everlee’s surgeries was just over 80 minutes. The recovery was equally fast. Within a few hours of the procedure, he was able to climb two flights of stairs, and within two days of the procedure he was able to walk without a crutch. Further healing was still needed, but his mobility began to return quickly.

Everlee’s real-life example shows what modern hip replacement technology now makes possible. Surgical options for hip pain are now more accessible, allowing patients to choose surgery earlier instead of relying on less effective preventative care or pain management, and even to be performed as outpatient procedures.

When people imagine hip replacement surgery, says Everlee, “they may think of the surgeries from 20 or more years ago where patients may have been in the hospital for several days, followed by endless painful therapy sessions, after which they still struggled to walk ‘normal’ for a very long time.” Hip replacement has come a long way since then and even has come a long way since Everlee began with EOS. And part of the reason for this advance, this tremendous improvement in the prospects for hip pain sufferers relates to the work he was involved in near the start of his career. Today Everlee gets to walk around bragging about the technology he sells, “I’m proud to say my chassis is now equipped with 3D printed titanium hip cups produced on the systems I sell every day!”