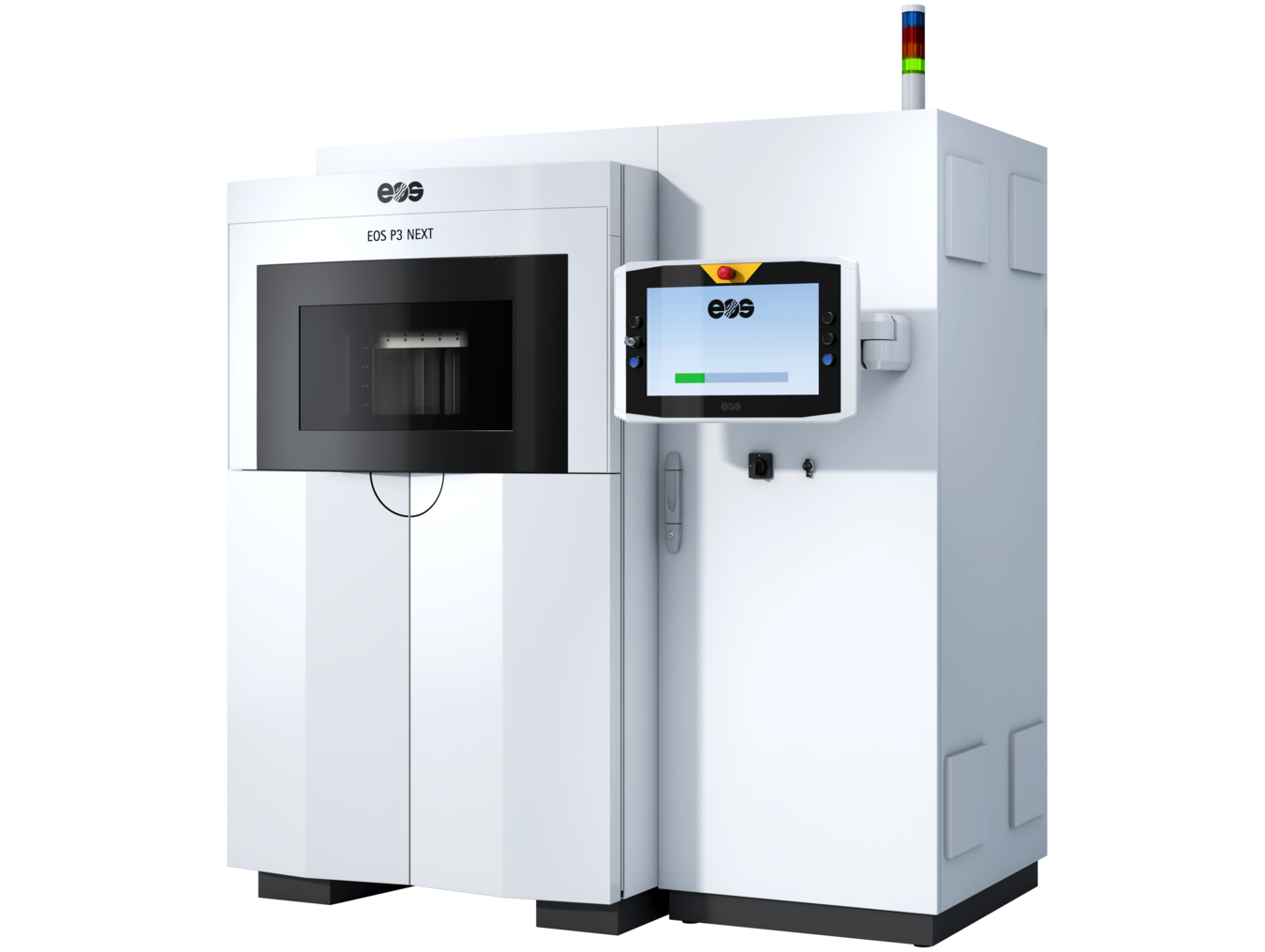

Maximum Versatility to Grow at Your Own Pace

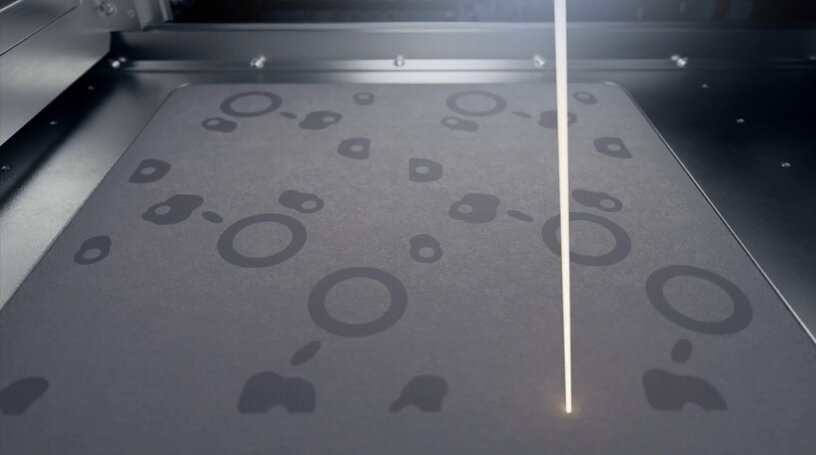

33 % faster pre-heating time

More homogeneous part quality over job height

180 mm/s recoater speed

Increase system productivity

Faster process control

36 % faster build process and more uniform temperature profiles across layers

External cooling module

90 % less cool down time and faster unpacking of builds

| BUILD VOLUME | 340 x 340 x 600* mm (13.4 x 13.4 x 23.6 in) |

| Laser Type | CO₂; 1 x 70 W |

| Scan Speed | up to 6.0 m/s (19.7 ft/s) |

| Focus Diameter | approx. 480 µm (0.01890 in) |

| Power Supply | 1 x 32 A |

| Power Consumption | max. 10.0 kW / typical 2.1 kW |

| Machine Dimensions | 2030 x 1270 x 2400 mm (79.9 x 50.0 x 94.5 in) |

| Recommended Installation Space | min. 4530 x 3970 x 3000 mm (178.3 x 156.3 x 118.1 in) |

| Weight | approx. 1400 kg (3086 lbs) |

| Software | EOS BUILD , EOS SYSTEM SUITE |

* M 290 Series: including build platform and application dependent. M 300, M 400 & M4 ONYX Series: including build platform.

** For machine dimensions, please contact us

Materials & Processes

The EOS P3 NEXT enables consistent achievement of the necessary quality for target applications by providing extended access to parameters for optimizing both quality and productivity. With enhanced parameter controls, users can fine-tune process settings for superior quality and performance. Additionally, the new reuse-optimized materials ensure a lower total cost of ownership (TCO), making previously unattainable business cases feasible.

EOS Software Solutions

EOS Build Polymer is designed to streamline the assignment and optimization of process parameters, including the use of ready-to-use EOS Material Sets. This powerful tool offers process development and optimization, advanced exposure strategies and seamless data prepatarion workflow. Ensure a smooth and integrated process from design to production.

EOS System Suite provides comprehensive access to all machine data, enabling effective management and control of production processes, including data for quality assurance. It streamlines workflows and provides full control on the shopfloor and part quality and a 30 % reduction in order-to-print lead time.

View our EOS Software

EOS Service Solutions

EOS Service ensures fully secured system performance, providing peace of mind for your operations. With remote support solutions, you can access expert assistance with just one click, all backed by the highest security standards. The service safeguards continuity and helps you maintain control over your total cost of ownership. Additionally, configurable premium options offer flexible and customizable services to meet your specific needs. With the FullServiceFlex package, customers can achieve up to 90 % system availability, ensuring maximum productivity and reliability.