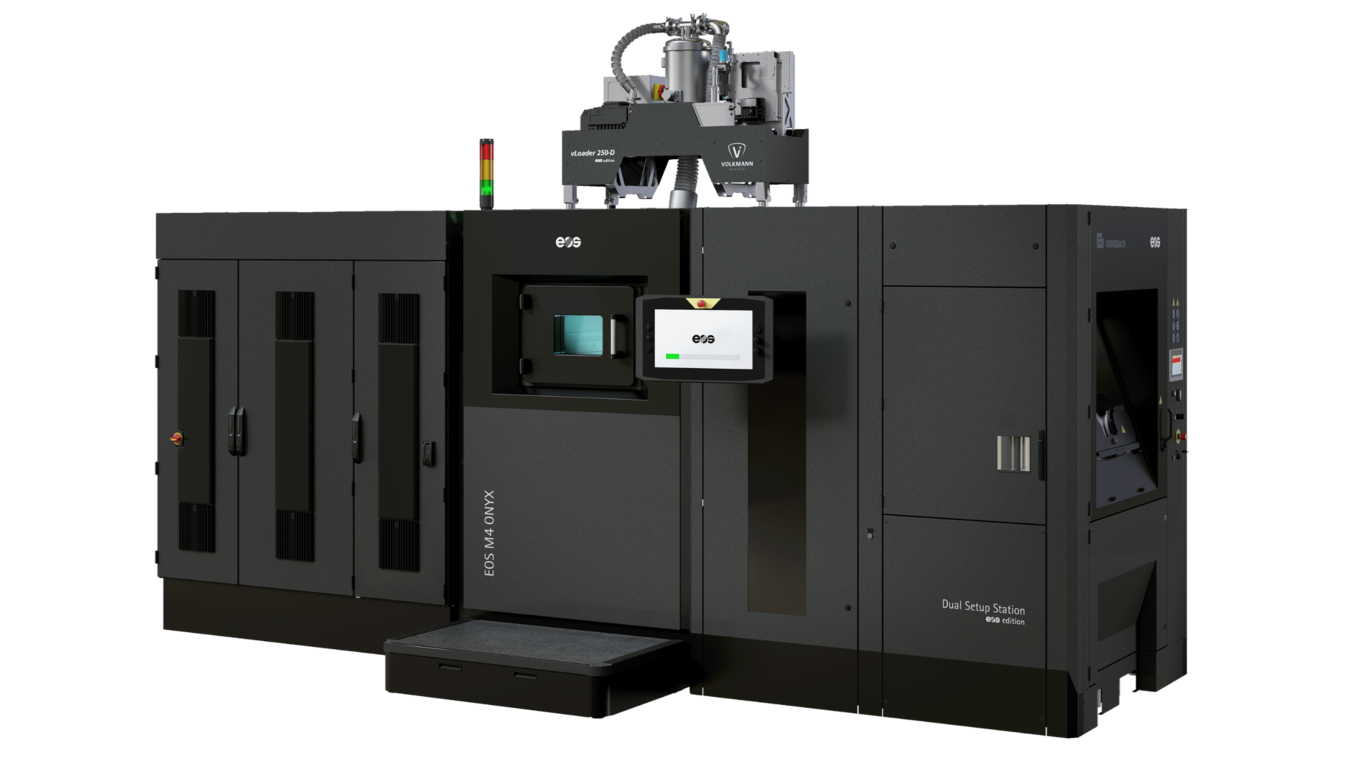

Setting a New Standard in Industrial Metal 3D Printing

Engineered for maximum productivity and reliability, the EOS M4 ONYX combines a spacious build volume with cutting-edge laser technology and intelligent process control. Delivering consistent high-quality results, it empowers manufacturers to scale additive production with confidence.

Have a Closer Look

Smart Waste Handling

RFS Pro filter system simplifies disposal, reduces hazardous waste, and eliminates extra filter media.

Efficient Powder Management

Closed-loop automation with the Volkmann Automated Powder Handling – EOS Edition, which ensures safety and process efficiency.

Optimized Gas Flow

Homogeneous gas flow ensures clean optics, consistent part quality, and shorter purge times.

Maximized Build Volume

30% more space with a build size of 450 × 450 × 400* mm – ideal for large parts and higher throughput.

*including build platform

Smart Process Optimization

EOS Smart Fusion reduces supports, improves surface quality, and minimizes post-processing effort.

Automated Job Handling

Overnight starts and fast job changeovers (<30 min) with the Grenzebach Dual Setup Station – EOS Edition.

Next-Gen Laser Power

Up to six advanced Light Engines deliver high precision and maximum productivity.

| BUILD VOLUME | 450 x 450 x 400* mm (17.7 x 17.7 x 15.7 in) |

| Laser Type | Yb-fiber laser; 6 x 400 W |

| Presicion Optics | 6 F-theta-lens(es); 6 High-speed scanner(s) |

| Scan Speed | up to 7.0 m/s (23.0 ft/s) |

| Focus Diameter | approx. 90 µm (0.00354 in) |

| Power Supply | 3 x 54 A |

| Power Consumption | max. 45.0 kW / typical 29.0 kW |

| Compressed Air Supply | 7 Bar; 20 m³/h (102 psi; 706 ft³/h) |

| Machine Dimensions | 5500 x 2370 x 2730 mm (216.5 x 93.3 x 107.5 in) |

| Recommended Installation Space | min. 7100 x 6000 x 3300 mm (279.5 x 236.2 x 129.9 in) |

| Weight | approx. 5700 kg (12566 lbs) |

Build volume including build platform

Materials & Processes

The EOS M4 ONYX combines high-performance hardware with a robust material and process portfolio for demanding industrial requirements. At launch, validated processes include Ti64 with a new 60 µm parameter set, and IN718, ensuring consistent part quality across diverse applications.

The Ti64 60 µm process offers faster build rates, improved microstructure, reduced porosity, and better surface finish. Optimized powder utilization minimizes waste, supporting sustainability and lowering total cost of ownership. Advanced process control further enhances productivity and quality.

With these capabilities, the EOS M4 ONYX unlocks new opportunities for scalable metal additive manufacturing in aerospace, energy, and industrial sectors.

Get Inspired

Expand Your AM Knowledge & Skills

EOS Software Solutions

EOS Software for Metal delivers a transparent, connected workflow from design to production. Open interfaces like OPC UA and the EOSPRINT API integrate with CAD tools such as Siemens NX, streamlining data preparation, reducing errors, and cutting lead time by 30%. EOS Build is the foundation for efficient additive manufacturing. It enables data preparation and job optimization via EOSPRINT with full control over process parameters. EOS Hub allows remote machine monitoring. As a site license, EOS Build covers your entire machine park for consistent quality and streamlined workflows.

Smart Monitoring fingerprints reference jobs and compares them with serial builds, reducing non-destructive testing by up to 50%. Thermal management features like Smart Fusion and Replay improve surface finish, reduce supports and post-processing. Beam shaping and low-angle processes boost productivity and enable complex geometries. EOS System Suite bundles essential software for scaling and industrializing AM production. It includes EOSTATE Quality Reports, Powder Bed Monitoring, and EOSCONNECT Core for complete machine and sensor data access. Seamless integration with MES, CAQ, or PLM systems supports data-driven decisions and compliance with industry standards.

EOS Service Solutions

EOS Service ensures fully secured system performance, providing peace of mind for your operations. With remote support solutions, you can access expert assistance with just one click, all backed by the highest security standards. The service safeguards continuity and helps you maintain control over your total cost of ownership. Additionally, configurable premium options offer flexible and customizable services to meet your specific needs.

With the FullServiceFlex package, customers can achieve up to 97 % system availability, ensuring maximum productivity and reliability in industrial production environment, with a joint EOS–customer co-operation in ramp-up phase.