Helping Pioneer Zero-Emission Aviation with 3D Printed Thermal Management

Conflux Uses Additive Manufacturing to Produce Lightweight Cooling System for Hydrogen-Electric Vertical Takeoff Aircraft

“We’re excited to work with Conflux, whose reputation for delivering at Formula 1 speed combined with AS9100D manufacturing and quality certification will be critical in enabling Vertiia to become the world’s first long-range passenger-capable hydrogen VTOL”

Simon Coburn | Hydrogen Systems Lead | AMSL Aero

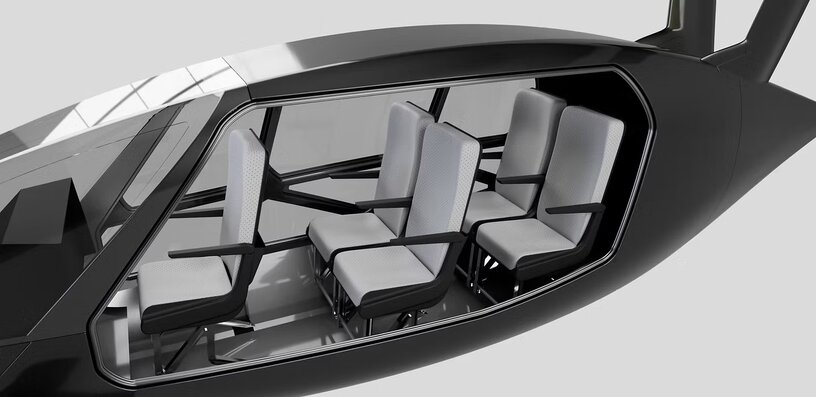

Conflux Technology collaborated with Australian aircraft manufacturer AMSL Aero to develop a custom cooling solution for Vertiia, a hydrogen-powered vertical takeoff and landing (VTOL) aircraft. This cooling solution is made from Conflux’s patented 3D printed heat exchanger technology, enabling effective and lightweight thermal management of the hydrogen fuel cell system for this groundbreaking zero-emissions aircraft.

Designed to fly up to 1,000 kilometers (621 miles), Vertiia pushes the limits of what electric aviation can do. Unlike conventional electric aircraft limited by battery capacity, Vertiia uses hydrogen fuel cells, which generate electricity without emitting CO₂. But the energy generated by hydrogen fuel cells generates significant heat - especially during energy-intensive maneuvers like takeoff and hovering –requiring a fresh approach to designing and manufacturing an advanced cooling system.

Challenge

Design a high-performance, compact cooling system for a hydrogen-electric aircraft

Hydrogen fuel cells offer enormous benefits for zero-emission aviation, a groundbreaking innovation in the quickly emerging advanced air mobility market. For Vertiia, fuel cells always need to remain within precise temperature limits during critical phases like takeoff, flight, and landing. Any overheating could compromise system efficiency or safety.

Traditional cooling systems add bulk and weight - unacceptable in an aircraft where every gram matters. The challenge: create a lightweight, compact, and highly responsive cooling solution that integrates seamlessly into the aircraft’s tightly constrained geometry and performs under highly dynamic thermal loads.

This is crucial during vertical flight, where hydrogen fuel cells experience high transient heat loads and rapid shifts in temperature.

Solution

Additive manufacturing with EOS metal 3D printing and Conflux’s patented heat exchanger design

Conflux Technology, a global innovator of 3D printed thermal systems, leveraged its experience in motorsport and aerospace to deliver a new generation of high-performance heat exchangers for Vertiia.

Computational Fluid Dynamics (CFD) guided the early design process, simulating heat transfer under real flight conditions. These heat exchangers are not just optimized for performance; they are built to endure the demanding thermal cycles and spatial constraints of vertical takeoff and sustained flight.

This approach enables highly efficient thermal transfer while minimizing volume and weight - essential for aviation. It also allows for rapid iteration: in the first development phase, Conflux produced three novel heat exchanger concepts tailored to the needs of fuel cell architecture.

All three designs use EOS laser powder bed fusion (LPBF) systems and EOS Aluminum AlSi10Mg material, producing an ultra-compact, thin-walled heat exchanger with high surface area density and fluid-optimized internal geometries.

Results

A lightweight, high-performance cooling system for the world’s first long-range hydrogen-electric VTOL aircraft

The collaboration between AMSL Aero and Conflux has already delivered tangible results. In phase one, three heat exchanger designs were delivered, demonstrating the ability to manage heat during vertical lift and rapid power transitions. These components are compact, high-efficiency, and precisely tailored for integration into Vertiia’s architecture.

The program has now moved into phase two: system-level integration and testing of a full-scale prototype within the actual powertrain. This will validate performance under real-world conditions, ensuring that the fuel cells can maintain optimal temperature and efficiency across a full flight profile.

Conflux’s role in the project marks another step forward in applying additive manufacturing to aerospace challenges - beyond propulsion into broader energy management systems.

“Hydrogen fuel cells represent a transformative technology in Australia’s pursuit of sustainable energy solutions. We are proud to incorporate our heat exchange technology to enhance the efficiency and performance of Vertiia’s hydrogen fuel cells”

Michael Fuller | CEO | Conflux Technology

“Our partnership with Conflux Technology is a great example of the ecosystem of advanced manufacturers and developers we are working with to build here in Australia through our co-development approach. In Vertiia, we are building a hydrogen-electric aircraft that flies record-breaking distances at Formula 1 speeds, making Conflux, with its history of innovation in motorsport and aviation, a great partner for us”

Adriano Di Pietro | CEO | AMSL Aero

With the combined strengths of advanced additive manufacturing and high-performance thermal management engineering, this partnership is helping pioneer a cleaner, more efficient future for aviation.