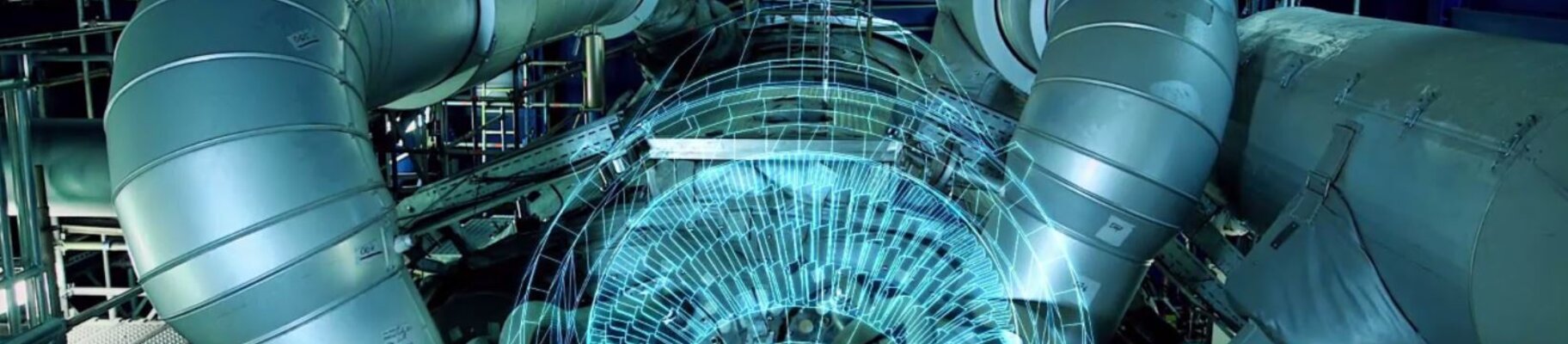

3D Printing for High Performance Industrial Gas Turbines

Siemens | Case Study

Swedish-based company, Siemens ENERGY, manufactures gas turbines for power generation in industrial and oil & gas applications. The performance spectrum of these Siemens industrial turbines ranges between 15 and 60 MW. Besides construction, the Siemens subsidiary also provides long-term service and maintenance for these engineering masterpieces. In an effort to help reduce maintenance costs, Siemens works with the development and implementation of Additive Manufacturing technology, utilising EOS technology and equipment.

"Additive Manufacturing opens up new dimensions for us in the use of integrated design and production. This technol ogy enables us to manufacture and repair components for our industrial gas turbines far quicker than before. At the same time the functionality and performance of the part is increased."

Dr. Vladimir Navrotsky | Head of Technology and Innovation, Siemens Energy Service | Oil & Gas and Industrial Applications

Challenge

The gas turbine consists of an air inlet, compressor, combustor, turbine and hot gas outlet. The air going through the engine is compressed by the compressor. In the combustion chamber the compressed air is mixed with fuel and burned in order to increase the kinetic energy of the flow. In the turbine the kinetic energy of the flow is converted into mechanical energy. This mechanical energy is used to turn the gas turbine compressor and generator (to generate electricity) or other driven equipment (e.g. compres- sor to pump the gas/oil through the pipelines). During operation the components in the engine's hot gas path are exposed to high temperatures, at times in excess of 1,000°C (e.g. blades and vanes). This, in turn, leads to a high level of wear of the hot gas path components.

This is also true for the burner tip – the point at which the ignition of the fuel-air mixture takes place. Here, the effects of wear and tear can be clearly seen and measured. The manufacturer undertook rigorous testing to establish a prescribed operating period after which the burners typically need to be repaired.

Conventional repair procedure required prefabrication of big sections of the burner tip.

This prefabricated unit is used for replacement of the burner tip after the specified operation time (cutting out the old one and welding on the prefabricated one). Conventional repair procedure can be time-consuming involving a significant number of sub- processes and examinations. To help simplify and speed up the repair procedure Additive Manufacturing technology was implemented at Siemens.

Solution

Undertaking such an operation requires an innovative partner. Siemens found just that in EOS: in addition to having the right Additive Manufacturing technology, EOS was also able, within a short time frame, to individually adapt one of its in-house machines – an EOSINT M 280 – for metal processing.

The alterations concerned, in particular, the scale of the machine's interior, which had to be enlarged to accommodate the 800 mm burner. The manufacturer also amended further hardware components such as a camera system and an optical measuring system and made corresponding adjustments to the software. EOS carried out the extensive re-working of the EOSINT system in under a year.

From the outset it was clear that the approach was reaping benefits. Rather than replacing a large portion of the burner tip, Siemens began by removing the damaged material only. Moreover during repair, former versions of the burners in the fleet could be re-built to the latest design. This meant that older fleet burner versions could not only be repaired, but also improved – thus bringing new meaning to the term “Additive Manufacturing".

Results

Figures, data and facts clearly detail the success of the new repair process. Siemens ENERGY will be able to make a significant impact on the central concern – the reduction of the repair time frame: for the operator it is equally important that the turbines are quickly ready to return to service. This also opens up additional opportunities for potential cost reductions with regard to the repair process as well as maintenance.

In addition to improving its own repair process, Siemens can now offer its customers strategic advantages: Thanks to this new process, experts can make improvements to turbine technology by integrating the components into the repair process. In this way, operators can make use of the latest technology, even if their turbines have seen years of service.

Dr. Vladimir Navrotsky, Head of Technology and Innovation at Siemens Energy Service, Oil & Gas and Industrial Applications, summarizes: “with this new repair technology we are looking to carry out these high precision jobs much more quickly."

It's not only the Swedish Siemens' subsidiary which views the project as a significant achievement. “We have successfully pushed our technology into the repair arena. We've shown that we are capable of modifying our system quickly to meet customer-specific requirements. In this case the modifications to both hardware and software were significant. Everyone involved can look back with satisfaction, not only at the end result but also the route to achieving it," says Stefan Oswald from EOS.

The Results at a Glance

- Innovative: old burner versions can quickly be brought up to the latest standards of technology

- Cost-effective: potential cost reductions already seen at an early stage

- -90 % reduction of time required for the repair process

EOS Case Studies

Explore three decades of pioneering 3D printing excellence with EOS