3D Printing for Implants & Surgery

Enabling Personalized, High-Performance Medical Solutions With AM

High clinical demands, patient-specific anatomies, and strict regulatory requirements are shaping the development and production of implants and surgical solutions. Precision, reliability, and reproducibility are essential - while scalability and performance remain critical.

Additive manufacturing enables patient-specific implants and advanced surgical solutions.

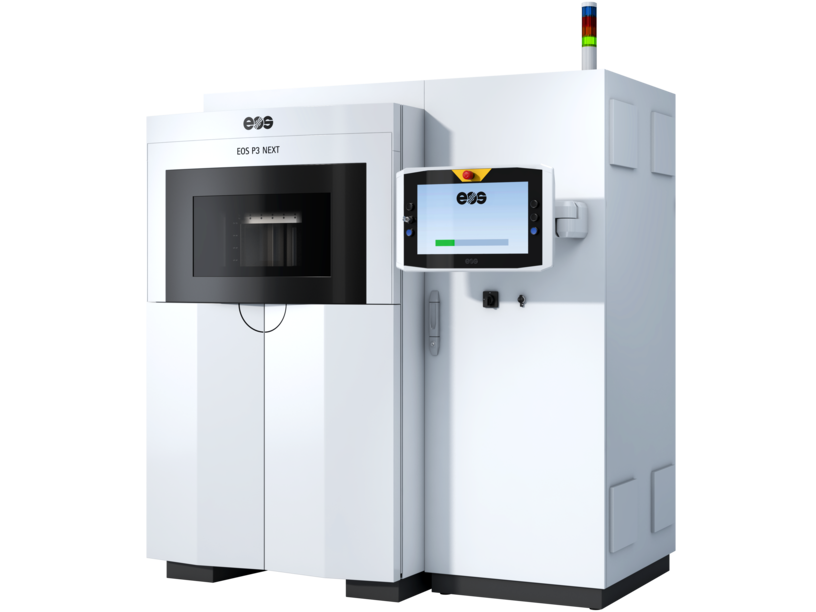

With more than 20 years of experience in medical additive manufacturing, EOS enables reliable serial production for implants and surgical applications. Our metal and polymer technologies deliver precision, reproducibility, and regulatory-ready quality at scale. Advanced materials such as Ti64 ELI, CoCr, and PA2200 meet the highest standards for biocompatibility and enable complex geometries, lightweight structures, and functional surfaces - including osseointegration features - that cannot be achieved with conventional manufacturing.

From concept development to certified serial production, EOS supports implant and surgical solution manufacturers with validated processes, application expertise, and scalable production systems - enabling safe, efficient, and compliant manufacturing.

Why Choose 3D Printing for Your Medical Production?

EOS Projects From Practice

AM for the Series Production in Medical

Additive Manufacturing is transforming the medical industry. It accelerates development, enables patient-specific care, strengthens supply-chain resilience, and supports scalable production of certified devices.

EOS is Your Proven AM Partner for Medical Applications for Metal & Polymer

AM gives manufacturers a powerful way to accelerate development, reduce risk, and deliver highly customized, clinically optimized devices at scale. From orthopedics to cranio-maxillofacial care, clinicians and patients benefit from improved fit, faster recovery, and enhanced osseointegration - while manufacturers gain shorter lead times, flexible production capacity, and consistent, repeatable quality.

- Faster to market: development cycles reduced from years to months

- Better clinical outcomes: up to 50% more bone-to-implant contact at 2 weeks

- On-demand, local manufacturing: lower inventory needs and reduced supply-chain risk

- Proven serial production: 500+ EOS M 290 medical systems operating worldwide

3D Printing Applications in Medical

FHC

-

Increased operating‑room efficiency & throughput

-

Cost savings through streamlined production & reduced material use

-

Enhanced quality ofcCare & differentiated patient experience

EOS Enables a New Step Forward

3D printed titanium implants simplify hip replacement surgery and improve patient outcomes. Advanced technology has helped make hip replacement an important option for younger patients - like Everlee.

- 3D printed surface geometry encourages fusion with bone

- Price of 3D printed implants has come down, so some hospitals now use it as standard

- Implant technology has helped make hip replacement easier and more accessible

Accelerating US Medical Device Approval

The EOS Medical Device Master File helps medical device manufacturers accelerate regulatory approval for the U.S. market. By providing pre-validated process, material, and machine data, EOS reduces regulatory complexity while protecting intellectual property and shortening time-to-market.

-

Faster regulatory approval and reduced time-to-market by avoiding redundant validation and testing

-

Lower regulatory effort and increased compliance confidence through the use of proven, pre-approved EOS data

Anatomics

Anatomics’ SpineBox™ system leverages EOS SLS 3D printing to pre-plan and personalize spinal fusion surgeries, significantly improving surgical efficiency, reducing radiation exposure and operating time, and enhancing patient outcomes.

- Improved efficiency of entire workflow from planning through recovery

- Radiation exposure reduced by 38.5 %

- Operating time reduced by 17 %

- All patients mobilized day one post-operation