3D Printing Innovations

Where We Go From Here

Future-Proof Technologies?

Challenge Accepted!

We are constantly working on the future: on the development of our additive manufacturing solutions, but also on the more general answers that industrial 3D printing can provide to challenges in different industries. Learn more about our latest 3D printing innovations and how our customers have solved their challenges with EOS additive technologies.

Our 3D Printing Innovations - Your Opportunities

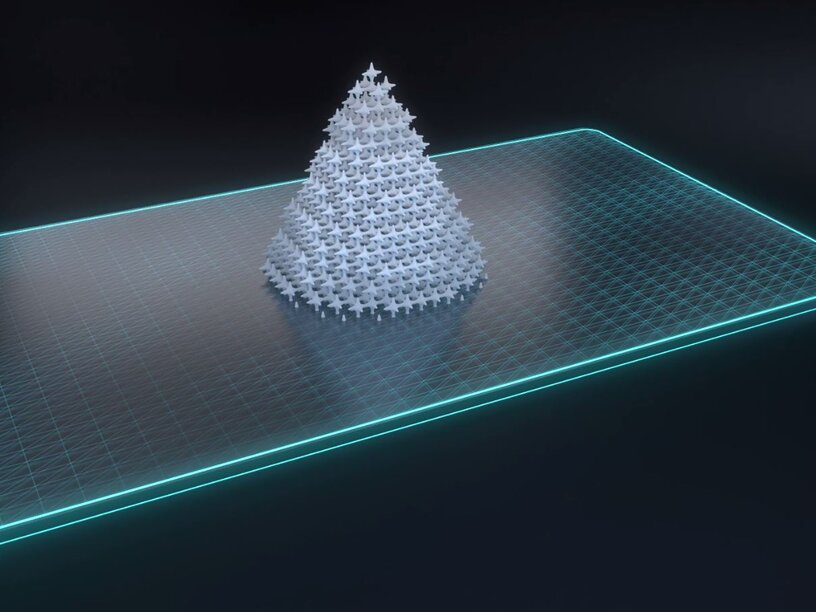

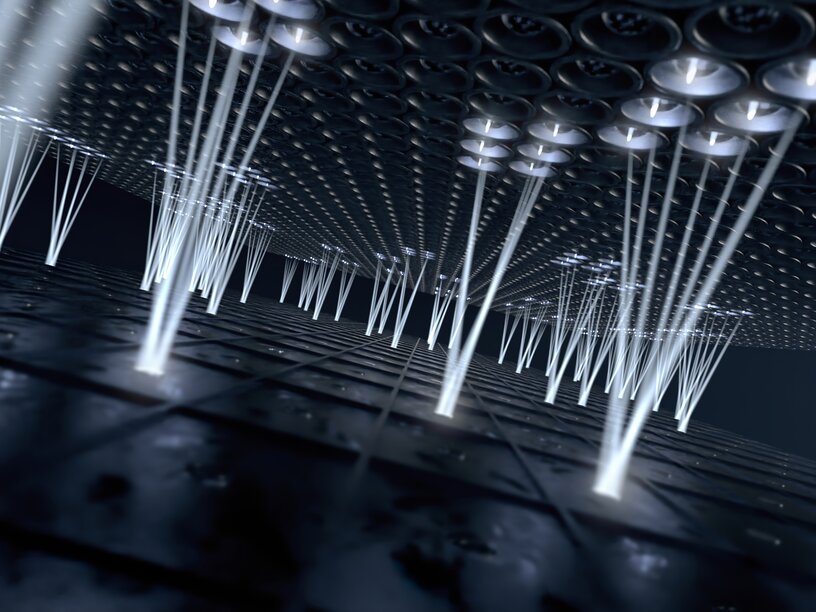

3D printing offers many benefits, from advanced technologies to more cost-effective printing processes and innovative materials. With a state-of-the-art 3D printer, you can produce high-quality parts faster and without expensive tooling. Instead, a digital design file is simply sent to the printer. Additive manufacturing also enables the creation of complex structures - opening up unprecedented opportunities for companies in a wide range of fields, including science, engineering and healthcare, as well as medical, aerospace and automotive.

EOS' advanced technologies could revolutionize your business model, too. Read more about our technology innovations and they enable our customers from different industries to be successful in the future.

Re-envisioning Metal 3D Printing: Breaking the Boundaries of Manufacturing

At the Pulse of Change

3D printing innovations are a fundamental part of the EOS story. We have been a pioneer in additive manufacturing for more than 30 years. During this time, we have perfected the laser powder bed fusion process and developed the ideal combination of 3D printing systems, materials and processes. Our technology delivers parts that meet the most demanding industrial requirements for dimensional accuracy, surface quality and strength. Together with our customers, we are constantly working to optimize our processes and technology, because we engineer for your success.