Our History

35 years of innovation and success in additive manufacturing

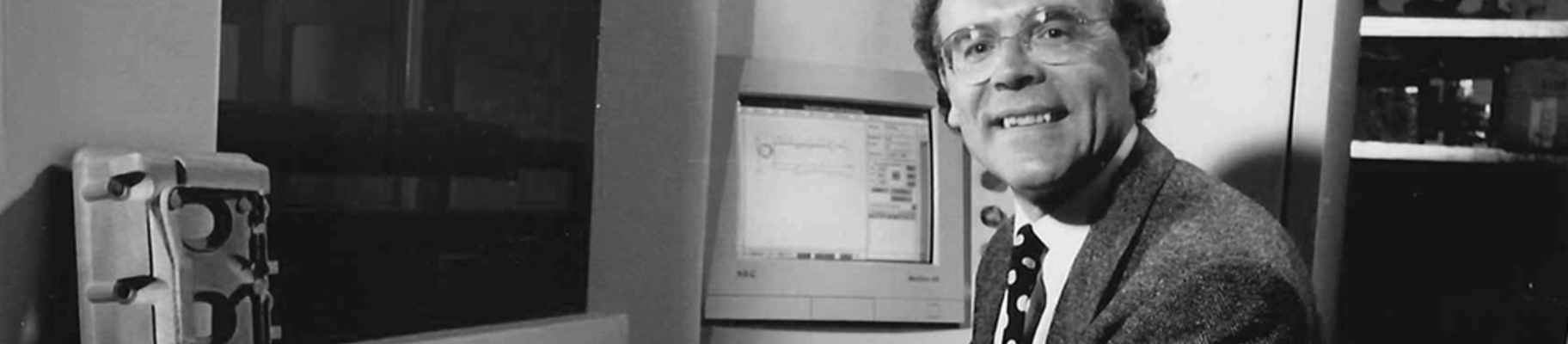

On April 24, 1989, Dr. Hans J. Langer founded EOS GmbH in Gräfelfing, a small municipality south of Munich. This marked the first day in our history, which has been shaped by pioneering spirit, conviction and courage ever since.

Today, EOS is a global leader in the industrial 3D printing of metals and plastics and offers integrated solutions in additive manufacturing (AM). The company currently employs more than 1,350 employees in 15 countries and serves customers around the globe.

The EOS Story

___1989

-

EOS GmbH is founded by Dr. Hans J. Langer and Dr. Hans Steinbichler.

-

The company first offers rapid prototyping (RP) solutions and sees its first market successes in the U.S.

___1990

-

BMW is the first customer to order the STEREOS 400 stereolithography (SLA) system.

-

The company relocates from Gräfelfing to Planegg.

-

Dr. Steinbichler sells his shares in EOS GmbH to Dr. Langer.

-

After just a year in business, EOS is becoming a technology leader for high-end rapid prototyping (RP).

___1991

-

The company introduces the STEREOS 400 stereolithography system.

-

EOS Electro-Optical Systems S.A.S. is founded in Lyon, France.

___1992

-

The STEREOS 600 system is launched, and first installed for Mercedes Benz.

-

EOS presents its layering build process for the first time at the Dayton RP Conference (U.S.).

___1993

-

EOS develops the world’s first active coating technology for stereolithography systems.

-

First systems sold in Japan (two STEREOS 600 machines).

-

The first two EOSCAN 100 systems are installed at BMW and IPT Aachen.

___1994

-

EOS becomes the world’s first provider of both SLA and laser sintering systems.

-

Carl Zeiss Jena buys a majority stake in EOS, maintaining it until 1997.

-

The company introduces the EOSINT P 350, the first European laser sintering system for manufacturing plastic prototypes.

-

Also introduced: the STEREOS Desktop model.

-

New metal system introduced: EOSINT M 160, the first commercial system for the Direct Metal Laser Solidification (DMLS) process.

___1995

-

Launched: EOSINT S 350, the world’s first sand laser sintering system for sand cores and molds.

-

Introduced: STEREOS MAX 600; the first system is installed at Foxbit in Italy.

-

The company also introduces the EOSINT M 250, the first generation of series-production DMLS systems; this marks the start of rapid tooling for metal.

-

EOS is now the technology leader for high-end rapid tooling systems.

___1996

-

Introduced: PA 1500, a polyamide material for the EOSINT P 350, and PA 1300, a glass-filled variation for the same system.

-

The first EOSINT S 700 sand laser sintering system is installed at BMW in Landshut.

___1997

-

EOS acquires worldwide patent rights for the introduction of laser sintering technology.

-

Introduced: Integrated Process Chain Management (IPCM), a peripheral for EOSINT S 700.

-

Introduced: PA 2200, the most successful LS material worldwide (based on its processability).

-

New company branch founded: EOS s.r.l. Electro-Optical Systems, in Milan, Italy.

___1998

-

EOS receives ISO 9001 certification for its quality management system.

-

Two new metal materials introduced: DirectMetal 50-V1 and V2, and DirectMetal 100-V3.

___1999

-

Introduced: EOSINT P 360, a plastic laser sintering system.

___2000

-

Launched: EOSINT P 700, the world’s first double-headed system (for plastic) with the highest build rate.

-

Founded: EOS Oy in Turku, Finland, for developing metal materials.

___2001

-

Founded: EOS Electro-Optical Systems Ltd. in Warwick, U.K.

-

Founded: EOS North America in Novi, Michigan (U.S.).

-

Introduced: EOSINT P 380, a new plastic laser sintering system.

-

Introduced: New DMLS system generation with the EOSINT M 250 Xtended.

___2002

-

EOS and The TRUMPF Group sign a mutual licensing agreement for DMLS technology.

___2003

-

Introduced: Alumide, an aluminum-filled fine polyamide material.

-

Introduced: DirectSteel H 20, a metal material for tool-making.

-

Introduced: EOSINT S 750, a new double laser sintering system.

___2004

-

Introduced: CarbonMide, a carbon-fiber-filled material made from fine polyamide.

-

Introduced: EOSINT M 270, the first commercial DMLS system with a fiber laser.

___2005

-

Founded: EOS India Branch Office in Chennai, India.

___2006

-

EOS and TRUMPF Group sign a patent licensing agreement with Concept Laser for the DMLS process.

-

The FORMIGA P 100, a plastic laser sintering system, sets new standards with “FORMIGA quality."

-

Introduced: PA 2210 FR, the world’s first flame-retardant plastic material.

-

Introduced: Quality management for metal materials.

-

Founded: EOS Singapore Pte. Ltd. in Singapore.

___2007

-

New plastic materials introduced: PrimePart DC, PrimePart ST, PA 2202 black, PA 2203 gray.

-

New metal material introduced: EOS Titanium Ti64.

-

Founded: EOS GmbH Korea Branch Office in Incheon City, South Korea.

___2008

-

EOS founder Dr. Hans J. Langer is honored with the Bavarian State Medal.

-

Introduced: EOSINT P 800, a plastic laser sintering system for processing EOS PEEK HP 3.

-

Introduced: Integrated Quality Management System (IQMS) and Integrated Process Chain Management (IPCM).

-

Launched: EOS CobaltChrome SP2, a CE-certified material for dental crowns and bridges.

___2009

-

Founded: EOS subsidiary in Chemnitz specializing in micro laser sintering.

-

Introduced: EOSINT P 395 and EOSINT P 760, plastic laser sintering systems.

-

Introduced: EOS NickelAlloy IN718 and EOS Aluminium AlSi10Mg metal materials.

-

Introduced: EOS Part Property Management to standardize the part properties.

___2010

-

Introduced: EOSINT M 280, a metal laser sintering system with 200-W or 400-W fiber lasers

-

Introduced: NickelAlloy IN 625, a metal material

-

Founded: Electro Optical Systems Nordic AB in Göteborg, Sweden, serving northern Europe and the Baltic states.

___2011

-

EOS passes the threshold of 1,000 laser sintering systems sold worldwide.

-

TCT Magazine selects Dr. Langer as one of the 20 most influential personalities in the field of additive manufacturing.

-

Introduced: Two quality assurance modules for metal applications — Laser Power Monitoring (LPM) and Comfort Powder Module (CPM).

-

New materials: Tungsten W1

___2012

-

Introduced: PrimePart FR (PA 2241 FR), the first flame-retardant material for the aviation industry.

-

Introduced: PrimePart PLUS (PA 2221), the first refresh-optimized laser sintering material (30% refresh rate).

-

Founded: EOS GmbH Electro-Optical Systems Ltd. in Hong Kong.

-

Introduced: FORMIGA P 110, a compact plastic system.

___2013

-

EOS opens an office and technology center in Shanghai.

-

Presented: EOS P 396, a plastic system equipped with EOSAME to homogenize the part mechanics.

-

Launched: EOS M 400 metal system and the first modular production platform.

-

Introduced: Plastic materials PrimePart ST (PEBA 2301) and PrimePart® FR (PA 2241 FR).

-

New Materials: StainlessSteel 316L

___2014

-

EOS celebrates its 25th anniversary.

-

The Krailling technology and customer center — and eventual EOS headquarters — opens.

-

Introduced: EOS M 290, a modular metal laser sintering system for series production.

-

Introduced: EOSYSTEM and EOSPRINT software, which enable decoupled data preparation — a milestone for AM industrialization.

-

Launched: PRECIOUS M 080, the first commercial system for processing gold

___2015

-

Introduced: AM recycling program for used powder.

-

Introduced: EOSTATE MeltPool, a quality assurance (QA) module for build process analysis.

-

Introduced: EOSTATE Everywhere, a QA module for insight into the process status.

-

Introduced: EOS CobaltChrome RPD, a CE-certified material for dental crowns and bridges.

-

Launched: EOS M 100, an entry-level system for the production of complex metal parts.

___2016

-

EOS founds the Additive Minds business division for technology consulting and knowledge transfer.

-

The company expands its U.S. presence, opening a new location in Pflugerville, Texas.

-

Presented: EOS M 400-4, the largest and fastest DMLS system (so far).

-

Launched: EOS P 770, a high-performance plastic system with a production volume greater than 150 liters.

___2017

-

Dr. Hans J. Langer is inaugurated into the “TCT Hall of Fame” for 3D printing.

-

EOS opens a new production site in Maisach.

-

Launched: EOS P 500, the world’s first automatable industrial system for polymer series production.

-

Presented: EOSPRINT 2, a new generation of data preparation and process management software.

-

Introduced: EOSTATE ExposureOT, allowing real-time monitoring of metal AM build processes.

-

Partnership: “NextGenAM” project with Premium AEROTEC and Daimler.

___2018

-

Launched: EOS P 810, the world’s first high-temperature laser sintering system for PEKK-CF.

-

Launched: EOS PA 1101, a polyamide material with high chemical resistance.

-

Introduced: EOS M 300 series, the first metal AM system equipped for digital production.

-

Opened: Innovation Center in Düsseldorf.

-

Founded: EOS Electro-Optical Systems Japan K.K. in Shinyokohama, Japan.

___2019

-

Marie Langer becomes the new CEO of EOS GmbH as the company celebrates its 30th anniversary.

-

Dr. Langer receives the German Leadership Award 2019.

-

Additive Minds receives the “Top Consultant 2019” award — again.

-

Launched: EOS CopperAlloy CuCrZr and Copper Cu, our first foray into copper-based additive manufacturing.

-

Launched: TPU 1301, a highly hydrolysis-resistant thermoplastic elastomer.

___2020

-

New metal materials: EOS ToolSteel 1.2709, NickelAlloy IN939, Copper CuCP.

-

Flagship project POLYLINE brings together 15 industry and research partners to develop a next-generation digitalized production line.

-

#3DPrintingAgainstCorona provides the industry with relevant data, impactful initiatives, and trustworthy downloadable files to help with shortages in Medical at the pandemic’s peak.

-

EOS Purpose Presentation: We exist to accelerate the world’s transition to responsible manufacturing with industrial 3D printing.

___2021

-

Launching our podcast Additive Snack to help businesses achieve growth and success through AM.

-

New materials: CaseHardeningsteel 20MnCr5, StainlessSteel 254.

-

Launched EOS Store — starting with refurbished systems and trainings.

-

EOS awarded Silver Leadership in Engineering Achievement Program (LEAP) award for the EOS M 300-4.

___2022

-

Customers use our first Virtual Reality Mobile App for the EOS M 290.

-

The EOS vlog “Blueprint” is online.

-

EOS’ Additive Minds Consultancy team is awarded the TOP CONSULTANT seal 2022.

-

New technology: Fine Detail Resolution (FDR) technology.

___2023

-

EOS and Wilson develop a first-of-its-kind airless basketball that only relies on a 3D-printed structure and research-grade materials to replicate the bounce of a traditional basketball.

-

Release of Smart Fusion — the first real-time intelligent heat management software focused on eliminating support structures while performing 2x-5x faster than other technologies.

-

New products for Responsible Manufacturing: The EOS Cost & Carbon Calculator. On top, EOS launches PA1101 as climate-neutral and PA2200 as a carbon-reduced polymer material.

-

Launched EOS M300-4 1kW