Growing with

Polymer 3D Printing

Unleash Your Potential Now!

EOS – The Trailblazers of Polymer 3D Printing

While industrial 3D printing promises more flexibility and creative freedom than traditional manufacturing, understanding different materials and technologies can be a challenge. Here’s your easy path into the limitless world of polymer 3D printing.

The 30-year span of EOS' experience and dedication in polymer additive manufacturing (AM) represents the perfect combination of reliable industrial-scale 3D printing systems, cutting-edge software, and a high-quality polymer materials portfolio. This has laid the foundation to produce end-use polymer parts that meet numerous industries' needs for high dimensional accuracy and homogeneous mechanical part properties.

Originating as a German engineering company, driving the future of polymer 3D printing will always matter more than resting on the laurels of our past. The unique balance of established and reliable technologies like selective laser sintering (SLS) and our experts' restless urge to innovate is what allows EOS to offer effectively integrated polymer industrial 3D printing solutions. EOS polymer 3D printers, materials, and services support flexible, cost-efficient production of end-use polymer parts at any scope — from rapid prototyping to industrial-scale manufacturing.

Break Free of Manufacturing Limitations with Industrial Polymer 3D Printing

If there is one benefit of our organization's experience that we prize above all others, it's that we intimately understand the challenges our polymer customers face and tailor our solutions to meet those pain points.

-

Reliability

Our polymer 3D printers and powders form the basis of industrial-quality, durable and stable parts, at a high level of dimensional accuracy and reproducibility — no matter the complexity of your design parameters. -

Compliance

The parts our printers produce are pure polymer, meeting rigorous standards of highly regulated industries such as aerospace and medical device manufacturing. -

Customization

EOS CAM tools enable comprehensive control and optimization of all relevant build parameters. That offers experts greater freedom to create parts that precisely meet the specifications of their applications. - Responsibility

EOS responsible products are designed to reduce the carbon emissions of your production. The climate-friendly polymer materials enable the production of carbon-reduced, and even climate-neutral parts. - Expertise

The award-winning Additive Minds Consulting team is always available to help you develop sustainable strategies that empower long-term success in polymer 3D printing.

Identifying the Right EOS System for Your Production Needs

EOS’ industrial 3D printing systems can integrate seamlessly into existing polymer production infrastructure or be the centerpiece of a state-of-the-art shop floor. As your organization grows, your EOS solution can scale and grow alongside your business.

Our reliable polymer 3D printers have different build space sizes and laser power ratings. The portfolio ranges from powerful compact machines processing a wide range of materials, to ultra-fast two-laser systems for high-quality serial part production to innovative FDR solutions to produce delicate parts with a high-detail resolution.

Naturally, our SLS and FDR technology only require consumed material and power for part production. That not only gives cost transparency, but the waiving of agents or binders excludes risks right from the start because they have an impact on material properties like durability and biocompatibility of parts.

Our Portfolio of Polymer 3D Printers

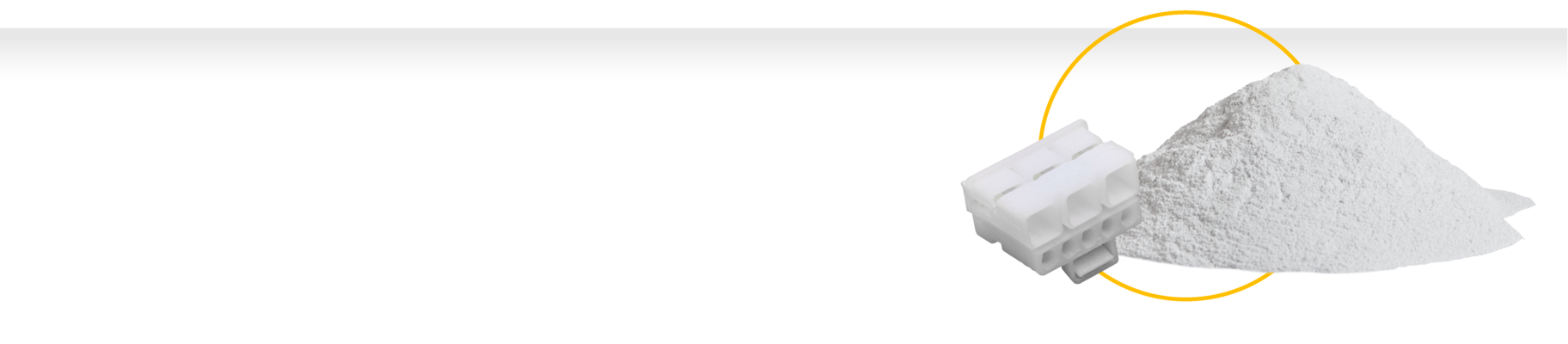

Material Selection for Your Polymer Additive Manufacturing System

At EOS, we have exceptional materials expertise and a comprehensive portfolio of plastic materials. Our portfolio currently encompasses the following grades: Polyamides (PA), Thermoplastic Elastomers (TPE) and Polyaryletherketones (PAEK). The over 16 tried-and-tested materials and more than 28 validated processes can effortlessly be adjusted to the most diverse industry requirements and enhance application performance. Our PA 1101 and PA 2200 materials are also available in a carbon reduced and even neutral version.

Our material supply chain is quality-controlled from the source to delivery, ensuring regulatory compliance, lot traceability, flexible volumes and fast delivery. All of our materials, process parameters, and plastic 3D printers are aligned to provide reliable and repeatable part properties to exceed your production goals.