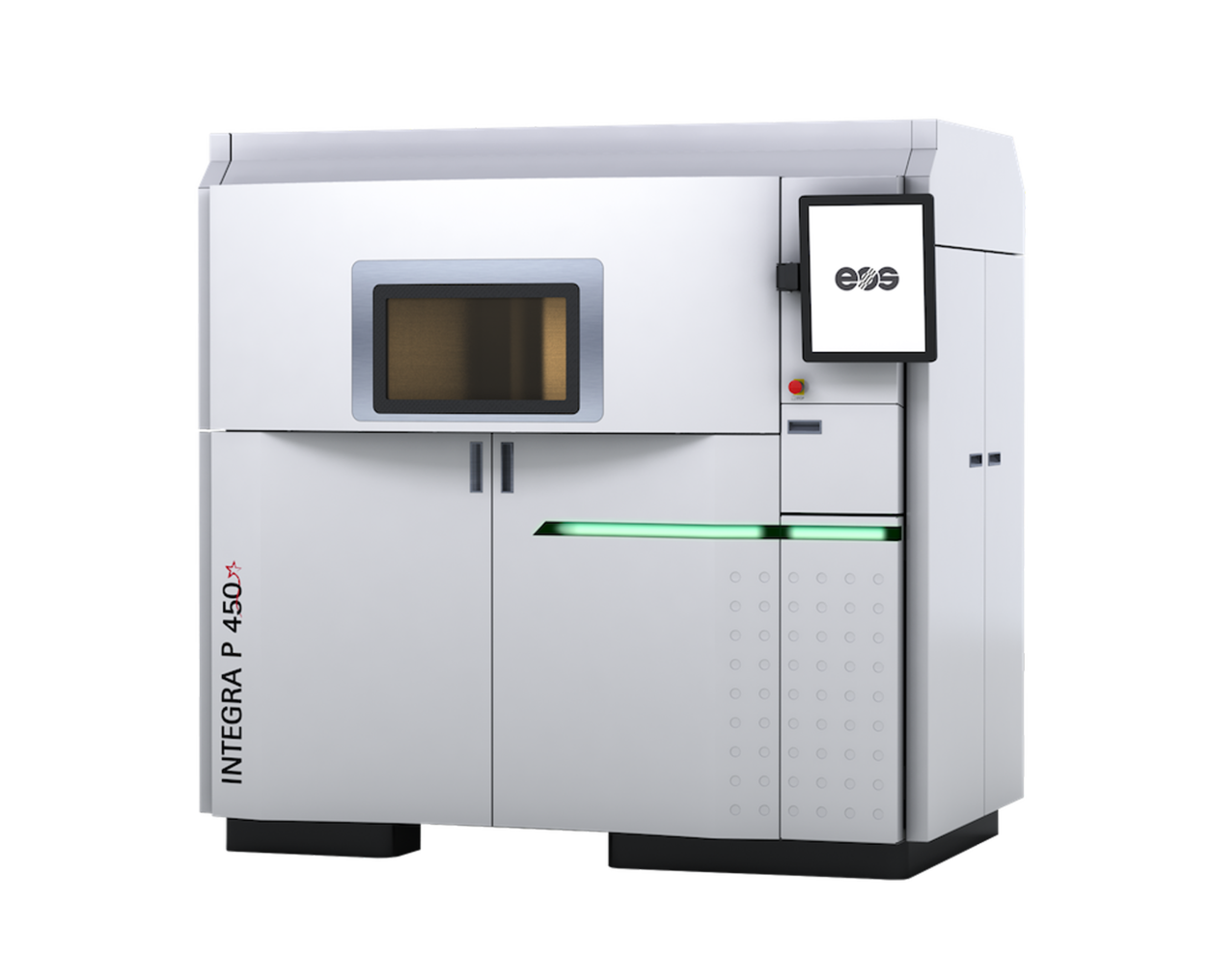

P 450

Built upon decades of industry feedback, the INTEGRA P 450 helps you move from prototyping to serial production.

This system is available only to customers in North America.

Bridging the Gap from R&D to Production

Built upon decades of industry feedback, the INTEGRA P 450 helps you move from prototyping to serial production.

| Build Volume | 420 x 420 x 500 mm (16.5 x 16.5 x 19.7 in) |

| Laser Type | CO₂; 1 x 120 W |

| Scan Speed | up to 12.7 m/s (41.7 ft/s) |

| Power Supply | 1 x 40 A |

| Power Consumption | max. 12.5 kW / typical 8.3 kW |

| Machine Dimensions | 2080 x 1320 x 2460 mm (81.9 x 52.0 x 96.9 in) |

| Recommended Installation Space | min. 4600 x 4100 x 3300 mm (181.1 x 161.4 x 129.9 in) |

| Weight | approx. 1815 kg (4001 lbs) |

Materials & Processes

EOS has extremely high materials expertise and a comprehensive portfolio of highly developed polymer materials for additive manufacturing. Our materials, systems and process parameters fit together optimally. With the right materials, you can realize the target property profiles in the best possible way for your products. Explore below which polymer materials are compatible with the INTEGRA P 450.

Get Inspired

Expand Your AM Knowledge & Skills

Software Solutions that Scale to Your Needs

From getting started to sustainable success

We always focus on your success. From a certified start in the 3D printing process to qualified system maintenance and globally available support with a convenient service portal which provides you with information around your machine and service tickets 24/7.

Pick the Service Plan that fits best for your needs and enjoy the option for remote service availabel for many of our solutions. Our EOS SystemCare Program is tailored to your specific requirements.