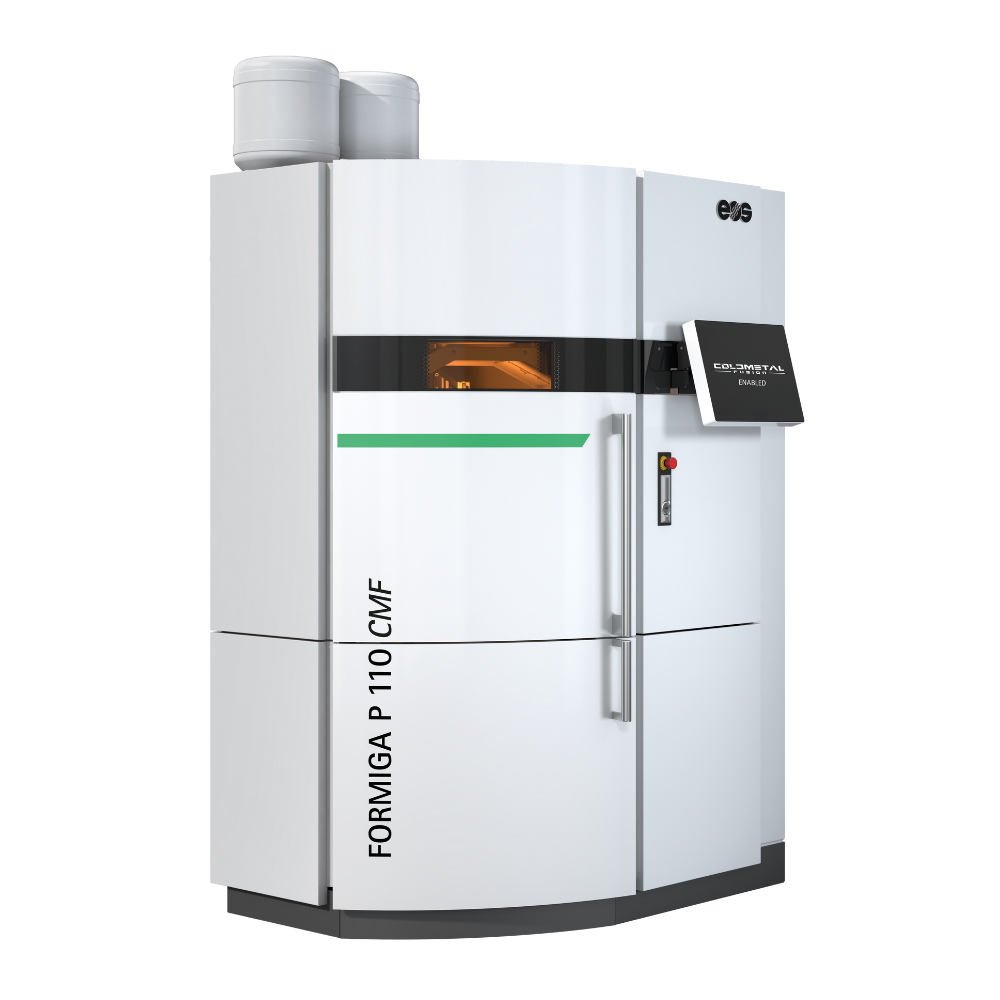

FORMIGA

P 110 CMF

Industrial ColdMetalFusion Machine for Titanium (Ti‑6Al‑4V) Production

Industrial ColdMetalFusion System for Titanium (Ti‑6Al‑4V) Production

The FORMIGA P 110 CMF is the first industrial ColdMetalFusion (CMF) system built on a proven EOS platform. It enables cost-efficient production of titanium components—especially impellers, diffusers, flow components and housings—for pumps, valves, and other industrial applications. The solution is optimized for CMF feedstocks developed by Headmade Materials and offers a reliable, low-temperature metal workflow with casting-like economics and additive manufacturing design freedom.

| BUILD VOLUME | 200 x 250 x 330* mm (7.9 x 9.8 x 13.0 in) |

| Laser Type | CO₂; 1 x 30 W |

| Presicion Optics | 1 F-theta-lens(es); 1 High-speed scanner(s) |

| Scan Speed | up to 5.0 m/s (16.4 ft/s) |

| Power Supply | 1 x 16 A |

| Power Consumption | max. 5.0 kW / typical 3.0 kW |

| Machine Dimensions | 1320 x 1067 x 2204 mm (52.0 x 42.0 x 86.8 in) |

| Recommended Installation Space | min. 3200 x 3500 x 3000 mm (126.0 x 137.8 x 118.1 in) |

| Weight | approx. 600 kg (1323 lbs) |

* M 290 Series: including build platform and application dependent. M 300, M 400 & M4 ONYX Series: including build platform.

** For machine dimensions, please contact us

Materials & Processes

EOS Build

All job and parameter optimization of EOSPRINT with ready-to-use EOS Material Sets - and more - now available as subscription model for efficiency and flexibility in additive manufacturing.

EOS Build offers a new approach to the industry-leading job and process optimization EOSPRINT software with ready-to-use EOS Material Sets, via two new subscription plans.

All EOSPRINT features to optimize build jobs and the process parameters make it a go-to solution for metal additive manufacturing (AM) are now available in the EOS Build and Build+ Plans.

The included high-quality "EOS Material Sets" for all standard materials are designed to deliver excellent results in the first run, saving time and money.